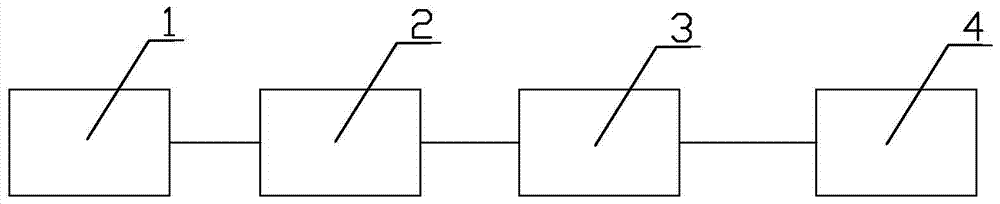

Production process of dibutyl phthalate plasticizer

A technology of dibutyl phthalate and a production process, which is applied in the field of production technology of dibutyl phthalate plasticizer, can solve the problems of frequent manual operation of the process, unstable product quality, high labor intensity and the like, and achieves the Reduced corrosion resistance, stable product quality, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

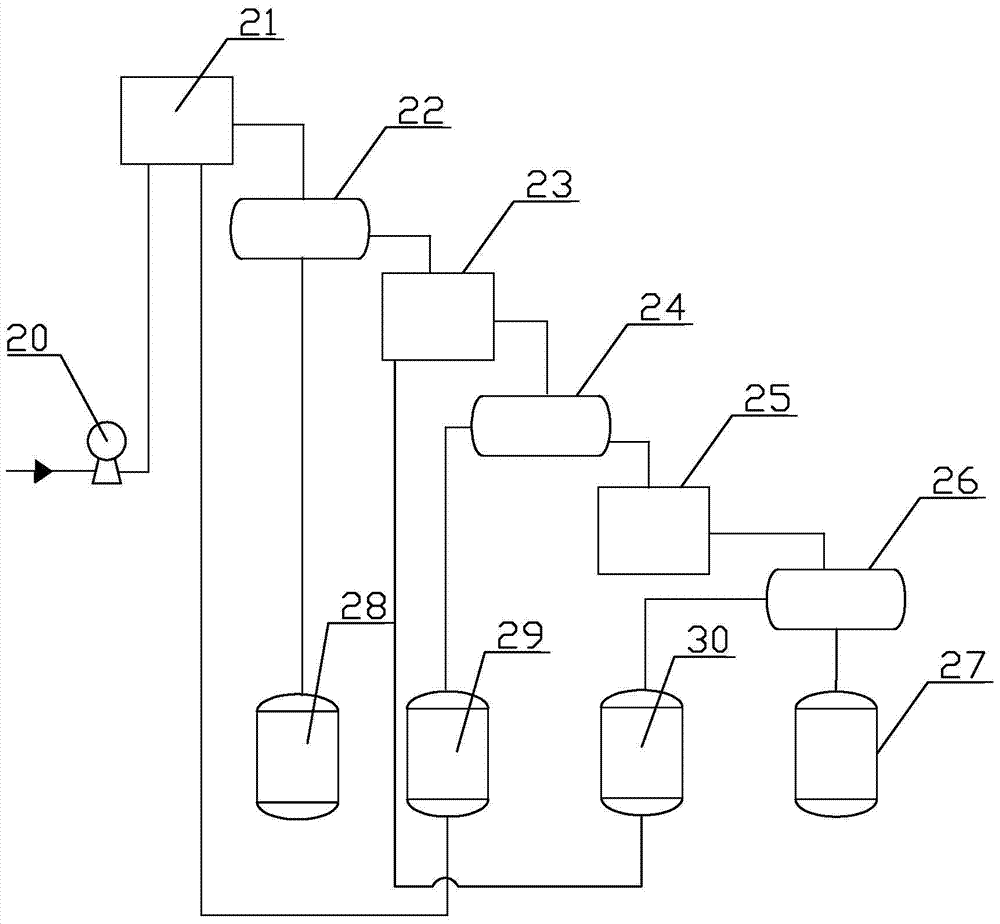

[0064] (1) Esterification process:

[0065] Add the raw materials phthalic anhydride, n-butanol and solid acid catalyst into the esterification reaction kettle through the first feed port, and then close the first feed valve. Under the agitation of the first agitator, use the internal coil to heat, and gradually raise the temperature to 150°C for 3 hours of reaction. The ester formed by the reaction is cooled by the second condenser and then enters the buffer tank.

[0066] Wherein, the mass ratio of phthalic anhydride, n-butanol and solid acid catalyst is: 1:1.4:0.02.

[0067] The gas phase evaporated in the esterification reaction kettle enters the esterification tower and contacts the reflux alcohol entering the top of the tower in reverse, then enters the first condenser to cool, and then enters the first alcohol-water separation tank for alcohol and water phase separation, and the water-saturated alcohol is separated from the second The upper part of the alcohol-water se...

Embodiment 2

[0083] (1) Esterification process:

[0084] Add the raw materials phthalic anhydride, n-butanol and solid acid catalyst into the esterification reaction kettle through the first feed port, and then close the first feed valve. Under the action of stirring by the first stirrer, use the internal coil to heat, and gradually raise the temperature to 120°C for 5 hours of reaction. The ester formed by the reaction is cooled by the second condenser and then enters the buffer tank.

[0085] Wherein, the mass ratio of phthalic anhydride, n-butanol and solid acid catalyst is: 1:1.2:0.05.

[0086] The gas phase evaporated in the esterification reaction kettle enters the esterification tower and contacts the reflux alcohol entering the top of the tower in reverse, then enters the first condenser to cool, and then enters the first alcohol-water separation tank for alcohol and water phase separation, and the water-saturated alcohol is separated from the second The upper part of the alcohol-...

Embodiment 3

[0102] (1) Esterification process:

[0103] Add the raw materials phthalic anhydride, n-butanol and solid acid catalyst into the esterification reaction kettle through the first feed port, and then close the first feed valve. Under the action of stirring by the first agitator, use the internal coil to heat, and gradually raise the temperature to 180°C for 1 hour of reaction. The ester formed by the reaction is cooled by the second condenser and then enters the buffer tank.

[0104] Wherein, the mass ratio of phthalic anhydride, n-butanol and solid acid catalyst is: 1:1.8:0.04.

[0105] The gas phase evaporated in the esterification reaction kettle enters the esterification tower and contacts the reflux alcohol entering the top of the tower in reverse, then enters the first condenser to cool, and then enters the first alcohol-water separation tank for alcohol and water phase separation, and the water-saturated alcohol is separated from the second The upper part of the alcohol-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com