A kind of polypropylene transparent material for fused deposition molding and preparation method thereof

A fused deposition modeling, transparent material technology, applied in the field of 3D printing technology and plastic processing, can solve the problems of opacity, reduce shrinkage and deformation of printed parts, expand polypropylene materials, etc., and achieve the phenomenon of improved light transmittance and large area crystallization The effect of suppressing and improving light transmittance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

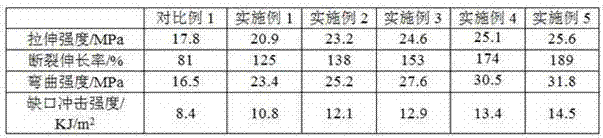

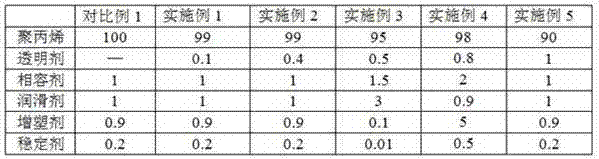

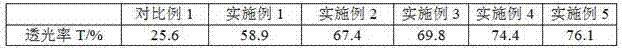

Embodiment 1

[0033] The polypropylene transparent material for fused deposition molding of this embodiment is made of the following raw materials: polypropylene 99g, transparent agent 0.1g, compatibilizer 1g, lubricant 1g, plasticizer 0.9g, stabilizer 0.2 g.

[0034] The polypropylene is a polymer obtained by polymerizing propylene alone. The polypropylene material used is produced by Sinopec Yangzi Petrochemical Co., Ltd., the brand is M02-V, and the transparent agent is tris(3,4,5-dimethyl Dibenzylidene) sorbitol, compatibilizer is maleic anhydride grafted polypropylene, lubricant is polyolefin, plasticizer is dioctyl phthalate, stabilizer is hindered phenol macromolecular antioxidant .

[0035] The preparation method of the polypropylene transparent material for fused deposition molding in this embodiment, the steps are as follows:

[0036] (1) Mixing of reagents and raw materials: first put polypropylene into the mixer, then add transparent agent, lubricant and plasticizer, and stir ...

Embodiment 2

[0040] The polypropylene transparent material for fused deposition molding of this embodiment is made of the following raw materials: polypropylene 99g, transparent agent 0.1g, compatibilizer 1g, lubricant 1g, plasticizer 0.9g, stabilizer 0.2 g;

[0041] The polypropylene is a polymer obtained by copolymerization of propylene and other olefins, the transparent agent is a sorbitol derivative, and its general chemical structure is , where the group R is The compatibilizer is maleic anhydride grafted polypropylene; the lubricant is a mixture of polyolefin and stearamide lubricant; the plasticizer is a mixture of dioctyl phthalate and epoxy soybean oil; stabilizer It is a mixture of antioxidant 1010 and four [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0042] The preparation method of the polypropylene transparent material for fused deposition molding in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0044] The polypropylene transparent material for fused deposition molding of the present embodiment is made of the following raw materials: polypropylene 95g, transparent agent 0.5g, compatibilizer 1.5g, lubricant 3g, plasticizer 0.1g, stabilizer 0.01g.

[0045] Wherein the polypropylene is a blend of a polymer obtained by the independent polymerization of propylene and a polymer obtained by copolymerization of propylene and other olefins; the transparent agent is a sorbitol derivative, and its general chemical structure is , where one group R is , another group R is The compatibilizer is maleic anhydride grafted polypropylene; the lubricant is a stearamide lubricant; the plasticizer is epoxy soybean oil; the stabilizer is an alkyl ester antioxidant.

[0046] The preparation method of the polypropylene transparent material for fused deposition molding in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com