Preparation method of modified papermaking sludge soil heavy metal passivator

A technology of heavy metal passivation agent and papermaking sludge, which is applied in the fields of chemical instruments and methods, soil conditioning materials, agriculture, etc. Solve problems such as complex mud composition, achieve the effects of reducing secondary pollution, easy operation, and simple modification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of modified papermaking sludge soil heavy metal deactivator, according to the following steps:

[0022] (1) After the papermaking sludge is precipitated and the supernatant is removed, the precipitate is dried at 55°C until the moisture content is 5%, and ground through a 60-mesh sieve for subsequent use;

[0023] (2) Take the above 4g papermaking sludge powder and place it in a beaker, add a NaOH solution with a mass concentration of 10% according to the solid-to-liquid ratio of 1g:50mL, and continue stirring for 1 hour;

[0024] (3) Add 20 mL of 3-mercaptopropyltrimethoxysilane solution with a mass concentration of 10% to the above mixture for modification, and keep stirring in a water bath at 30° C. for 8 hours;

[0025] (4) After the reaction, filter with suction, wash 3 times with ethanol with a volume concentration of 95%, then wash 3 times with deionized water, dry at 50°C to constant weight, and grind through a 100-mesh sieve to obtain Th...

Embodiment 2

[0027] The preparation method of modified papermaking sludge soil heavy metal deactivator, according to the following steps:

[0028] (1) After the papermaking sludge is precipitated and the supernatant is removed, the sediment is dried at 55° C. to a moisture content of 4%, ground through a 60-mesh sieve, and set aside;

[0029] (2) Take the above 4g of papermaking sludge powder and place it in a beaker, add a NaOH solution with a mass concentration of 20% according to the solid-to-liquid ratio of 1g:10mL, and continue stirring for 1 hour;

[0030] (3) Add 40 mL of thioglycolic acid solution with a mass concentration of 10% to the above mixture for modification, and keep stirring in a water bath at 50° C. for 4 hours;

[0031] (4) After the reaction, filter with suction, wash 4 times with ethanol with a volume concentration of 95%, then wash 4 times with deionized water, dry at 50°C to constant weight, and grind through a 100-mesh sieve to obtain The product passivator of th...

Embodiment 3

[0033] The preparation method of modified papermaking sludge soil heavy metal deactivator, according to the following steps:

[0034] (1) After the papermaking sludge is precipitated and the supernatant is removed, the precipitate is dried at 55°C until the moisture content is 5%, and ground through a 60-mesh sieve for subsequent use;

[0035] (2) Take the above 4g of papermaking sludge powder and place it in a beaker, add a NaOH solution with a mass concentration of 5% according to the solid-to-liquid ratio of 1g:100mL, and continue stirring for 1 hour;

[0036] (3) Add 5mL of 10% methyl thioglycolate solution to the above mixture for modification, and keep stirring in a water bath at 80°C for 1 hour;

[0037] (4) After the reaction, filter with suction, wash 3 times with ethanol with a volume concentration of 95%, wash 4 times with deionized water, dry at 50°C to constant weight, and grind through a 100-mesh sieve to obtain The product passivator of the present invention. ...

PUM

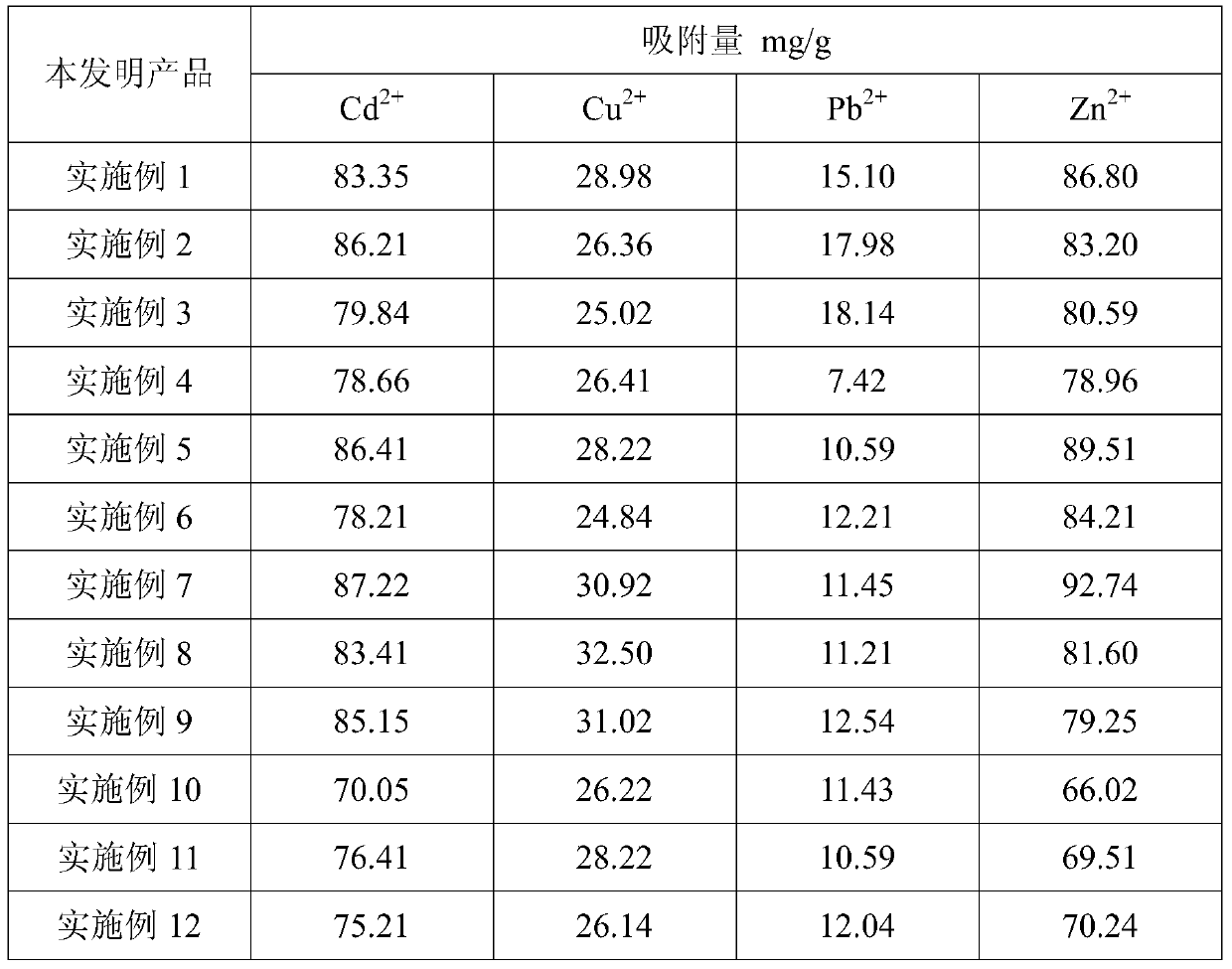

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com