Tea seed oil protein compound and preparation method thereof

A technology of tea seed oil and compound, applied in the directions of drug delivery, food science, drug combination, etc., can solve the problems of damage of protein bioactive components in tea seeds, waste of manpower and material resources, etc., to improve comprehensive development utilization rate and reduce nutrition. The effect of loss of ingredients and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

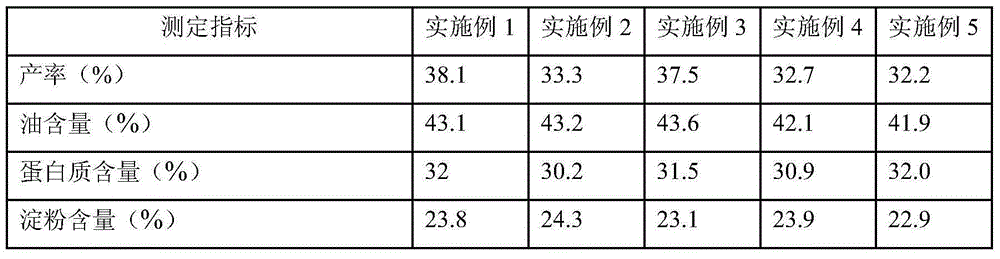

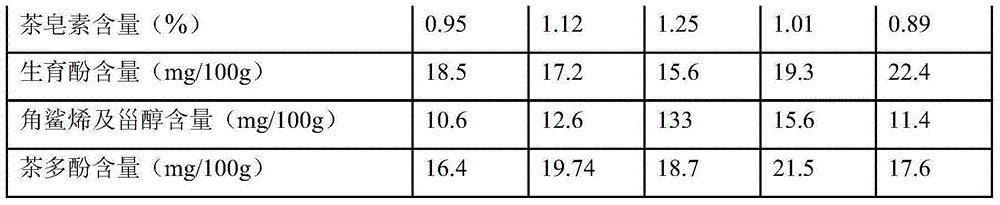

Examples

Embodiment 1

[0057] The preparation of embodiment 1 tea seed oil protein compound

[0058] 1. Prepare materials

[0059] The testa of the tea seeds is peeled off by a conventional method to obtain the tea seed kernels without the outer testa and inner testa, and the tea seed kernels are soaked in warm water at 50° C. for 21 hours to fully absorb water and soften the tea seed kernel cells.

[0060] Wherein, soaking is carried out under constant temperature condition, and the method for keeping constant temperature adopts conventional method.

[0061] 2. Refining

[0062] Mix the tea seed kernels softened by water absorption with water at a weight ratio of 1:3, and use a refiner to perform the first refining treatment to obtain tea seed kernel slurry A, and filter the slurry A with a 100-mesh filter cloth to obtain The filtrate I is stored for later use, and the obtained filter residue I is mixed with water, and placed in a refiner for the second refining treatment, wherein the weight rati...

Embodiment 2

[0073] The preparation of embodiment 2 tea seed oil protein compound

[0074] 1. Prepare materials

[0075] The testa of the tea seeds is peeled off by a conventional method to obtain the tea seed kernels without the outer testa and inner testa, and the tea seed kernels are soaked in warm water at 55° C. for 20 hours to fully absorb water and soften the tea seed kernel cells.

[0076] Wherein, soaking is carried out under constant temperature condition, and the method for keeping constant temperature adopts conventional method.

[0077] 2. Refining

[0078] Mix the tea seed kernels softened by water absorption with water at a weight ratio of 1:4, and use a refiner to perform the first refining treatment to obtain tea seed kernel slurry A, and filter the slurry A with a 100-mesh filter cloth to obtain The filtrate I is stored for later use, the obtained filter residue I is mixed with water, and placed in a refiner for the second refining treatment, wherein the weight ratio of...

Embodiment 3

[0082] The preparation of embodiment 3 tea seed oil protein compound

[0083] 1. Prepare materials

[0084] The testa of the tea seeds is peeled off by a conventional method to obtain the tea seed kernels without the outer testa and inner testa, and the tea seed kernels are soaked in warm water at 45° C. for 24 hours to fully absorb water and soften the cells of the tea seed kernels.

[0085] Wherein, soaking is carried out under constant temperature condition, and the method for keeping constant temperature adopts conventional method.

[0086] 2. Refining

[0087] Mix the tea seed kernels softened by water absorption with water at a weight ratio of 1:2.5, and use a refiner to perform the first refining treatment to obtain tea seed kernel slurry A, and filter the slurry A with a 100-mesh filter cloth to obtain The filtrate I is stored for later use, and the obtained filter residue I is mixed with water, and placed in a refiner for the second refining treatment, wherein the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com