System and method for producing cyanamide and aragonite type nano calcium carbonate through lime nitrogen

A nano-calcium carbonate, cyanamide technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology for material and surface science, nanotechnology, etc. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

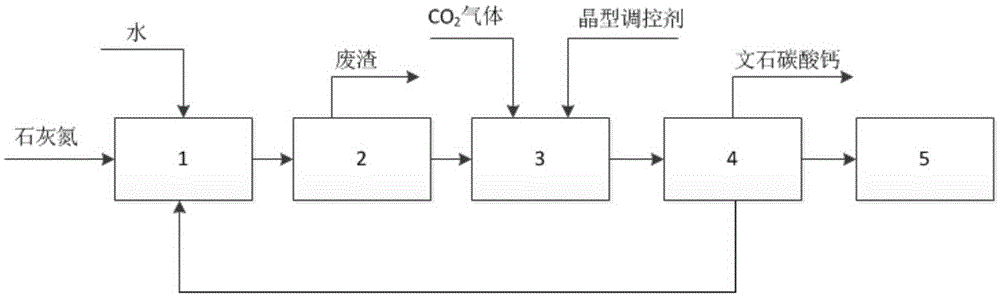

[0025] Use the method for the continuous production of cyanamide and aragonite-type nano-calcium carbonate system to produce cyanamide and aragonite-type nano-calcium carbonate with lime nitrogen, comprising the steps:

[0026] 1) Use the above-mentioned system for producing cyanamide and aragonite type nano-calcium carbonate with lime nitrogen;

[0027] 2) The water of lime nitrogen and 20L / h of pulverized nitrogen content 20wt% is passed continuously in the hydrolysis tank 1 with 10kg / h, the mixture after the hydrolysis is filtered through the first filter 2, and the filter residue is discharged through the waste residue outlet; The filtrate, 65ml / h phosphoric acid (crystal form modifier) and carbon dioxide gas are continuously transported to the high shear reactor 3, the reaction temperature is below 60°C, and the pH of the system reaches 9-10 by adjusting the flow rate of carbon dioxide;

[0028] 3) The product slurry discharged from the high-shear reactor is passed into...

Embodiment 2

[0030] Use the method for producing cyanamide and aragonite nano-calcium carbonate intermittently in the system of producing cyanamide and aragonite-type nano-calcium carbonate with lime nitrogen, comprising the steps:

[0031] 1) Use the above-mentioned system for producing cyanamide and aragonite type nano-calcium carbonate with lime nitrogen;

[0032] 2) Pass 15kg of pulverized lime nitrogen and 30L water into the hydrolysis tank, the mixture after the hydrolysis is filtered through the first filter, and the filter residue is discharged through the waste residue outlet; the filtrate and 0.1L phosphoric acid (crystal form control agent) into the high-shear reactor, carbon dioxide gas is continuously transported into the high-shear reactor, the reaction temperature is controlled below 60°C, and the system reaches pH=9 by controlling the amount of carbon dioxide gas introduced;

[0033] 3) The product slurry discharged from the high-shear reactor is passed through the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com