Production method of biological carbon-based ecological fertilizer

A production method and biochar technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of not paying attention to the protection of soil ecological environment, destroying soil ecological balance, and reducing the quality of agricultural and sideline products, so as to improve the ability of water and moisture conservation, overcome Continuous cropping obstacle and effect of reducing application amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

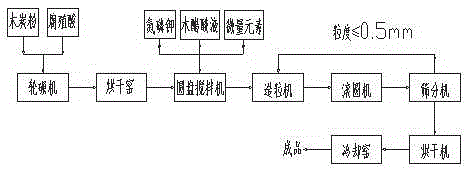

[0015] like figure 1 Shown, a kind of production method of biochar-based ecological fertilizer, this biochar-based ecological fertilizer is prepared from the following raw materials in parts by weight: 30 to 40 parts of biochar, 10 to 30 parts of humic acid, 10 to 30 parts of urea 20 parts, 5 to 15 parts of ammonium phosphate, 5 to 15 parts of potassium sulfate, 1 to 5 parts of wood vinegar, 0.5 to 2 parts of trace elements, and its production method is as follows:

[0016] 1) Use a crusher to crush forestry tree trunks, trunks, roots, waste wood, and paper strips with a diameter greater than 5 cm; use a hay cutter to crush crop straw, forestry branches, leather, wood, and scraps from wood processing plants , Weeds are cut into sections, each section is 2 to 10 cm in length; Mushroom slag, furfural slag, vinegar grains, distiller grains are dried with a dryer or drying yard, and the water content is less than 20%;

[0017] 2) The processed primary raw materials are transporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com