Method of preparing hexamethylene diisocyanate biuret through water vapor method

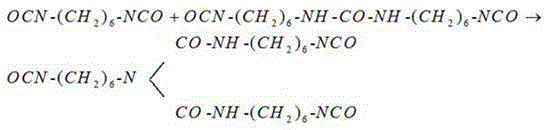

A technology of hexamethylene diisocyanate and water vapor, which is applied in the preparation of urea derivatives, chemical instruments and methods, and the preparation of organic compounds, and can solve the problem of free hexamethylene diisocyanate monomers and products with high chroma. Solve problems such as low chroma, achieve good economic and environmental benefits, good storage stability, and low chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

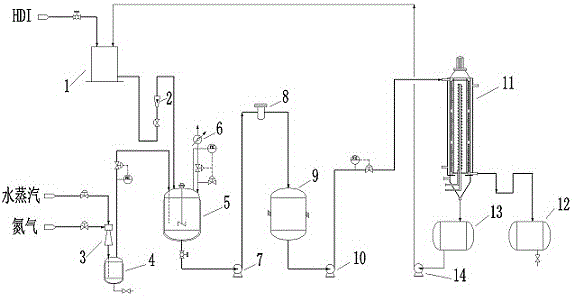

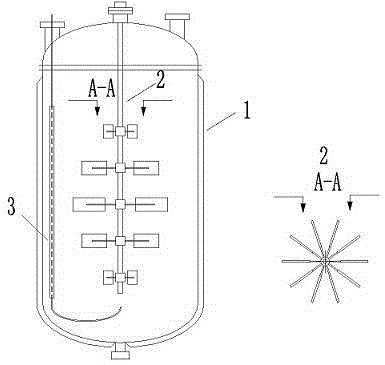

Method used

Image

Examples

Embodiment 1

[0042] 40kg of HDI was added to the reactor, and the temperature of the reactor was raised to 98°C. The molar ratio of HDI to water vapor was 5:1, and the volume flow rate of nitrogen and water vapor was mixed at 1:1. After dilution, the water vapor was evenly added to the reactor within 2 hours. After the addition, the reactor was kept warm for 0.5 hours, the temperature of the reactor was raised to 130° C., and the reaction was continued for 3 hours to obtain the crude product of HDI biuret. The crude product of HDI biuret passes through a filter to remove a little solid impurity, and is separated by a thin-film evaporator. The operating temperature is 160°C and the pressure is 20Pa. After separation and removal, the finished HDI biuret product is obtained. The free HDI mass content is 0.45%, and the NCO content is 21.8%, biuret group content 46.2%.

Embodiment 2

[0044]40kg of HDI was added to the reactor, and the temperature of the reactor was raised to 98°C. The molar ratio of HDI to water vapor was 5:1, and the volume flow rate of nitrogen and water vapor was mixed at 1:1. After dilution, the water vapor was evenly added to the reactor within 2 hours. After the addition, the reactor was kept warm for 0.5 hours, then the temperature of the reactor was raised to 120°C, and the reaction was continued for 3 hours to obtain the crude product of HDI biuret. The crude product of HDI biuret passes through a filter to remove a little solid impurity, and is separated by a thin-film evaporator. The operating temperature is 160°C and the pressure is 20Pa. After separation and removal, the finished HDI biuret product is obtained. The free HDI mass content is 0.52%, and the NCO content is 22.1%, biuret group content 45.7%.

Embodiment 3

[0046] 40kg of HDI was added to the reactor, and the temperature of the reactor was raised to 98°C. The molar ratio of HDI to water vapor was 5:1, and the volume flow rate of nitrogen and water vapor was mixed at 1:1. After dilution, the water vapor was evenly added to the reactor within 3 hours. After the addition, the reactor was kept warm for 0.5 hours, and the temperature of the reactor was raised to 130° C., and then reacted for 3 hours to obtain the crude product of HDI biuret. The crude product of HDI biuret passes through a filter to remove a little solid impurity, and is separated by a thin-film evaporator. The operating temperature is 160°C and the pressure is 20Pa. After separation and removal, the finished HDI biuret product is obtained. The free HDI mass content is 0.61%, and the NCO content is 21.3%, biuret group content 44.9%.

[0047] In the above examples, the percentage content of NCO groups is detected by di-n-butylamine titration; the content of free HDI mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com