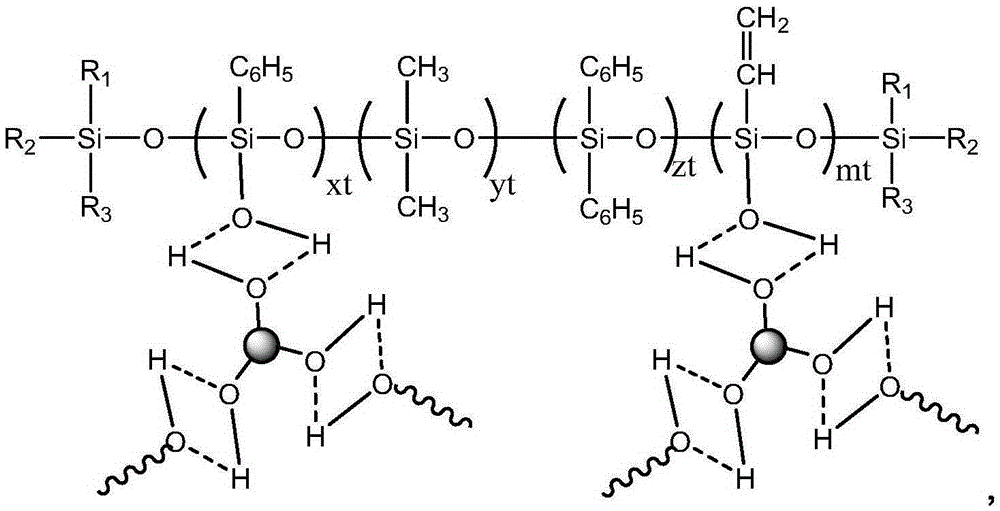

Nanometer silicon dioxide hybrid vinyl phenyl silicon intermediate material and preparing method and application thereof

A nano-silicon dioxide, vinyl phenyl silicon technology, applied in air quality improvement, adhesives, coatings and other directions, can solve the problems of rare, nano-particle agglomeration and sedimentation, achieve low thermal state dielectric loss, and the preparation method is simple and good. The effect of corona resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

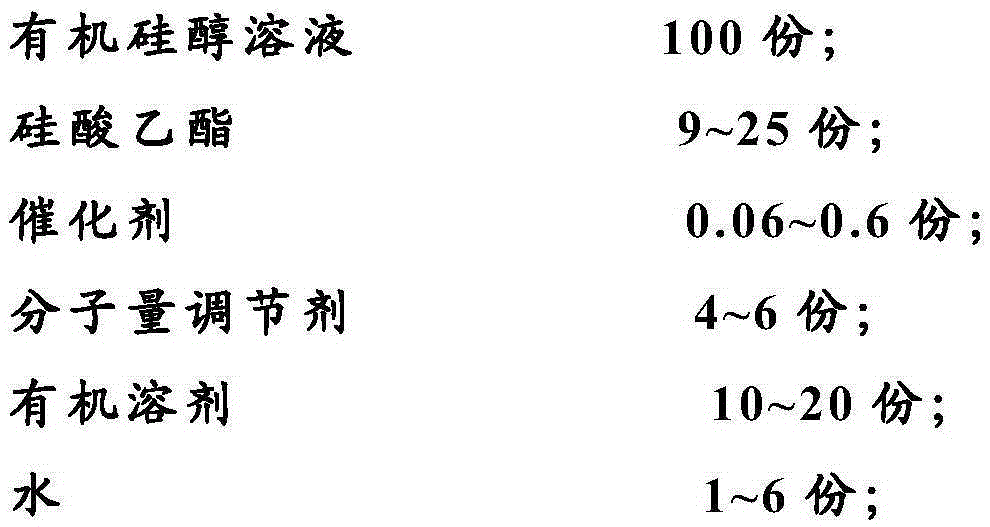

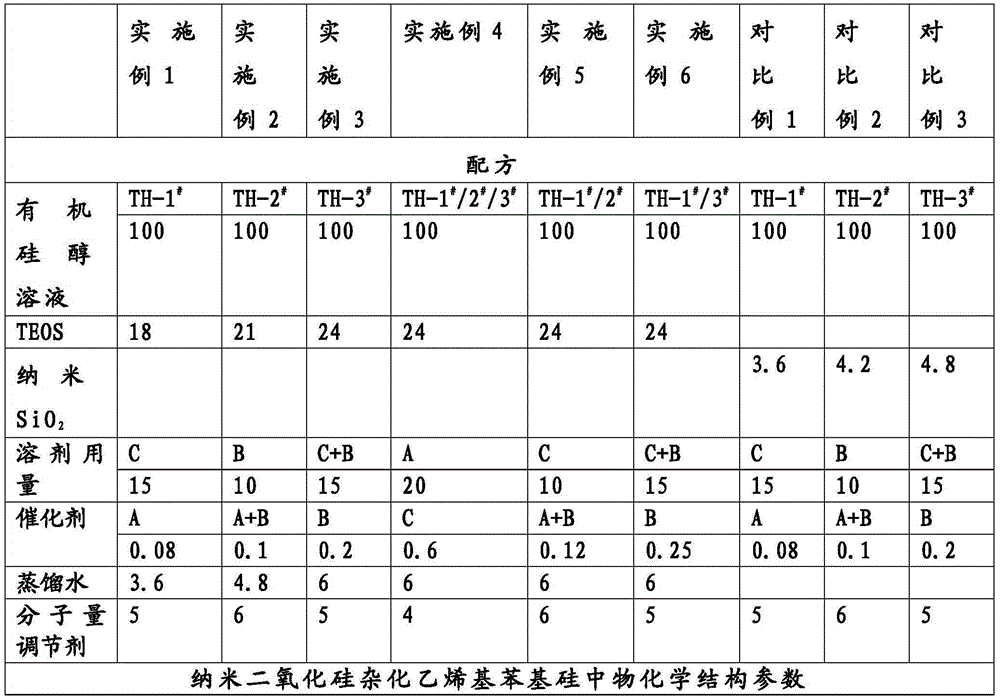

[0038]See Table 1 for the amount of raw materials added in Example 1.

[0039] A nano silicon dioxide hybrid vinyl phenyl silicon compound, which is prepared through the following steps:

[0040] (1), the organosilicon alcohol solution is added in the reactor with a stirring constant temperature device, then feed nitrogen to remove the air in the reactor, then add ethyl silicate 28 (TEOS-28) and organic solvent, at 20 Stir at ℃ for 0.5h, then raise the temperature to 60±5℃.

[0041] (2) Mix the catalyst, molecular weight modifier and deionized water evenly to make a mixed solution, then add the mixed solution dropwise to the reaction system after step (1), and control the mixed solution to be added dropwise within 1 hour , then heated up to 60°C to 80°C under stirring conditions to maintain the reflux reaction for 3h, and then distilled under reduced pressure at a temperature of 80°C and a pressure of -0.085MPa to remove the H produced in the polymerization reaction 2 O, eth...

Embodiment 2

[0044] See Table 1 for the amount of raw materials added in Example 2.

[0045] A nano silicon dioxide hybrid vinyl phenyl silicon compound, which is prepared through the following steps:

[0046] (1) Add the organosilicon alcohol solution into the reactor with a stirring constant temperature device, then feed nitrogen to remove the air in the reactor, then add ethyl silicate 28 (TEOS-28) and organic solvent, at 30 Stir at ℃ for 0.5h, then raise the temperature to 60±5℃.

[0047] (2) Mix the catalyst, molecular weight modifier and deionized water evenly to make a mixed solution, then add the mixed solution dropwise to the reaction system after step (1), and control the mixed solution to be added dropwise within 1 hour , and then heated to 60°C to 80°C under stirring conditions to maintain the reflux reaction for 2h, and then distilled under reduced pressure at a temperature of 100°C and a pressure of -0.095MPa to remove the H produced in the polymerization reaction 2 O, etha...

Embodiment 3

[0050] The amount of addition of raw materials in embodiment 3 is referring to table 1

[0051] A nano silicon dioxide hybrid vinyl phenyl silicon compound, which is prepared through the following steps:

[0052] (1) Add the organosilicon alcohol solution into the reactor with a stirring constant temperature device, then feed nitrogen to remove the air in the reactor, then add ethyl silicate 28 (TEOS-28) and organic solvent, at 35 Stir at ℃ for 0.5h, then raise the temperature to 60±5℃.

[0053] (2) Mix the catalyst, molecular weight modifier and deionized water evenly to make a mixed solution, then add the mixed solution dropwise to the reaction system after step (1), and control the mixed solution to be added dropwise within 1 hour , and then heated to 60°C to 80°C under stirring conditions to maintain the reflux reaction for 2h, and then distilled under reduced pressure at a temperature of 100°C and a pressure of -0.095MPa to remove the H produced in the polymerization rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com