Polylactic acid antibiosis master batch, and preparation method and application thereof

A technology of antibacterial masterbatch and polylactic acid, which is applied in the field of polylactic acid antibacterial masterbatch and its preparation and application, can solve the problems of harmful antibacterial silver ions, high processing temperature of polylactic acid, and long processing time, so as to prevent thermal degradation and avoid Effects of material degradation, extended molding methods and applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

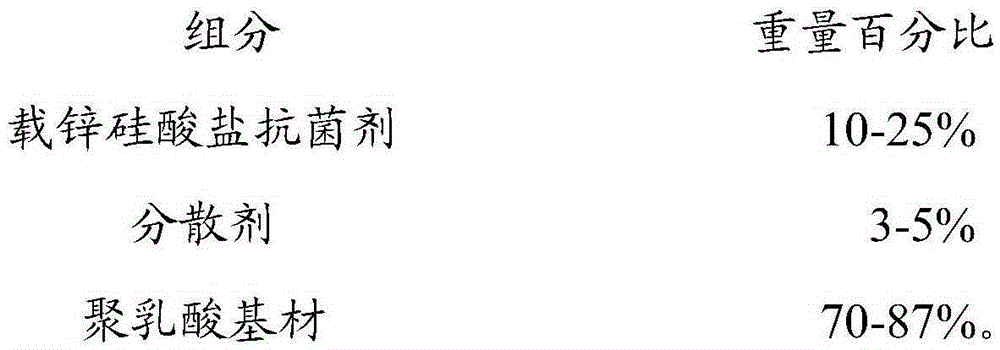

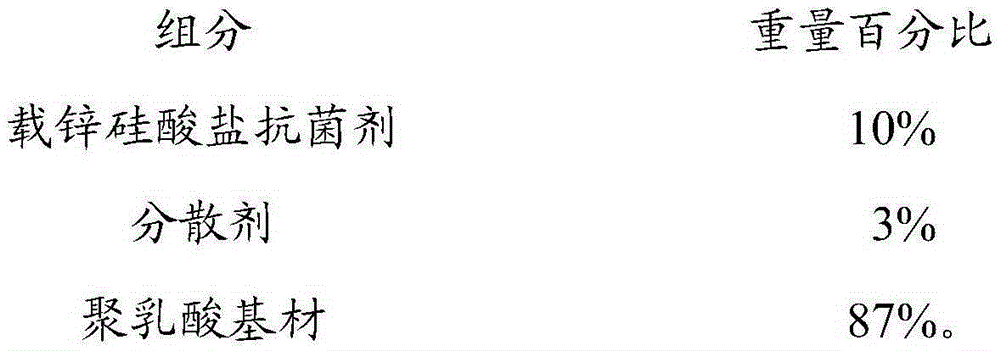

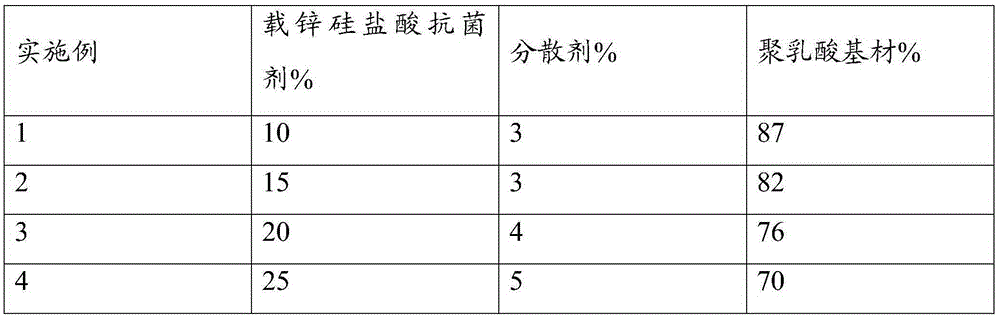

Embodiment 1-4

[0042] The preparation method of polylactic acid antibacterial masterbatch in embodiment 1-4 comprises the following steps:

[0043] (A) Weigh the zinc-loaded silicon hydrochloric acid antibacterial agent, dispersant, and polylactic acid base material according to the formula and pour them into the mixer. After mixing the ingredients at normal temperature for 2 minutes, they are discharged from the discharge port. Normal temperature mixing can prevent Polylactic acid thermal degradation;

[0044] (B) Pour the mixture into the hopper of the twin-screw extruder, turn on the feeding control switch, the speed of feeding is proportional to the speed of mixing, the mixture enters the twin-screw machine and is extruded into a linear shape, after 0-5°C After the cooling tank is cooled, the blower is air-dried, and the temperature of the air outlet of the blower is kept at 10-20°C. Finally, the mixed plastic strips enter the granulator for granulation, and become the final antibacteria...

Embodiment 5

[0057] The polylactic acid antibacterial masterbatch obtained in Example 1 is added to the polylactic acid base material, and plastic parts that are not exposed to a temperature higher than 70°C are formed by injection molding. It is especially suitable for forming plastic cutting boards. The processing process is as follows:

[0058] Mix the antibacterial masterbatch and polylactic acid base material, and put the mixed material into an injection molding machine equipped with a molding mold for injection molding. Adjust the temperature of the injection molding machine to 180-212°C, the mixture is stirred and dissolved by the screw, heated in the first, second, third, fourth, and fifth zones of the injection molding machine, injected into the mold, and passed through the second level of pressure holding After forming, the product is taken out immediately after cooling in the mold, placed in ice water for another 3 minutes and then taken out to obtain the finished product.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com