Research method for relaxation phenomenon of polymer via patterned charge mark

A patterning, polymer technology, applied in measurement devices, instruments, scanning probe microscopy, etc., can solve the problem of inability to observe the movement and relaxation process of polymer molecular segments in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, the preparation of polymer film and the construction of patterned charge

[0039] Polystyrene (PS) and polymethyl methacrylate (PMMA) were respectively dissolved in toluene to prepare a 2wt% solution. Drop the polymer solution on a single-sided polished silicon wafer, and spin coat it through a coating machine to form a film, and the speed is set at 6000r min -1 , the time is 1min. After taking it off, dry it in an oven at 100° C. for 1 hour to obtain a polymer film.

[0040] Preparation of PDMS stamps: firstly obtain a silicon wafer with a certain pattern by micromachining, then obtain a PDMS plate with a micro-nano pattern structure on the surface by means of contact reprinting, and obtain a specific seal by plating the upper and lower surfaces of the PDMS plate with gold. Micro-nano-patterned PDMS stamp.

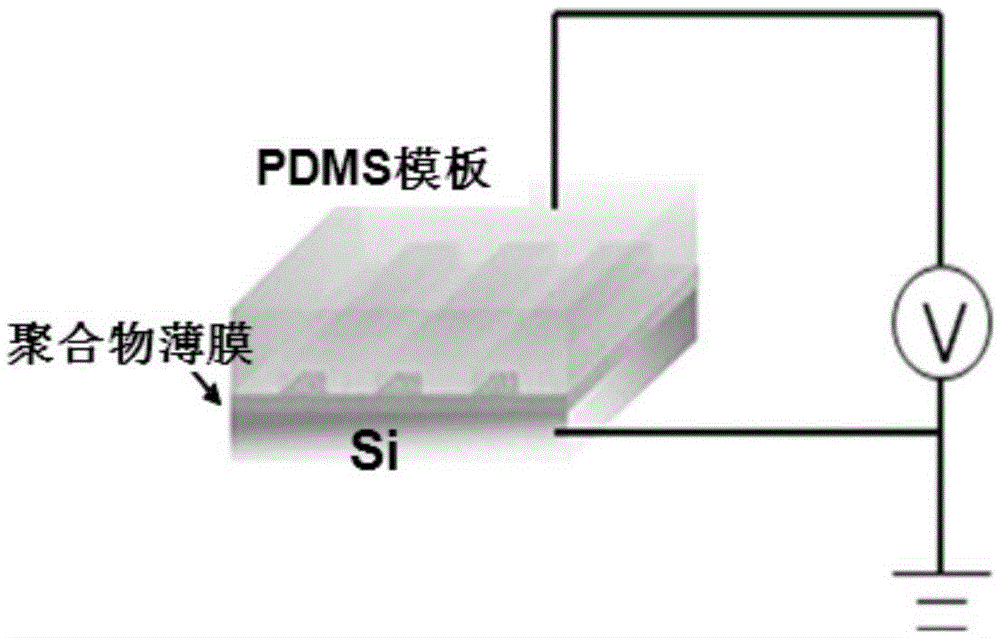

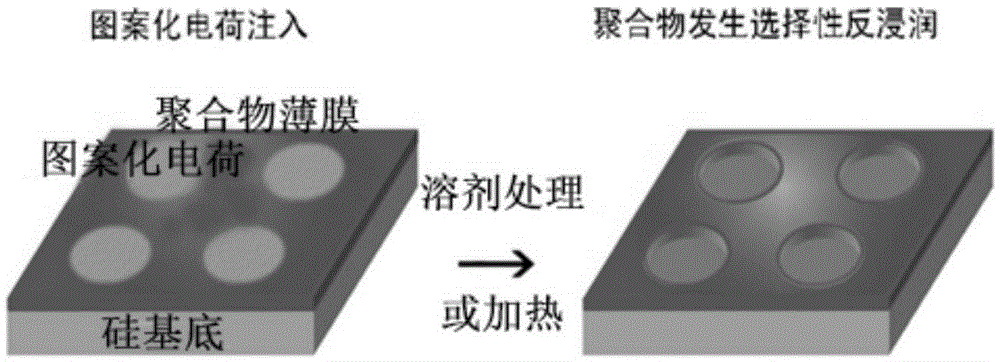

[0041] The surface of the polymer film is injected with electricity by an external power source, according to figure 1 Inject electricity accord...

Embodiment 2

[0044] The relaxation phenomenon of embodiment 2, PMMA under temperature stimulation

[0045] In this embodiment, the polymer used is polymethyl methacrylate (PMMA), and the heating temperature of the hot stage is 200°C. The glass transition temperature (Tg) of PMMA is 122°C. The reason why the temperature of the hot stage is set to 200°C, which is obviously higher than the Tg temperature of PMMA, is to complete the reaction of the polymer film in a very short heating time. During the infiltration movement process, if the heating time is longer, the charge will decay rapidly, so that the relaxation movement of the polymer under the action of the charge will be weakened.

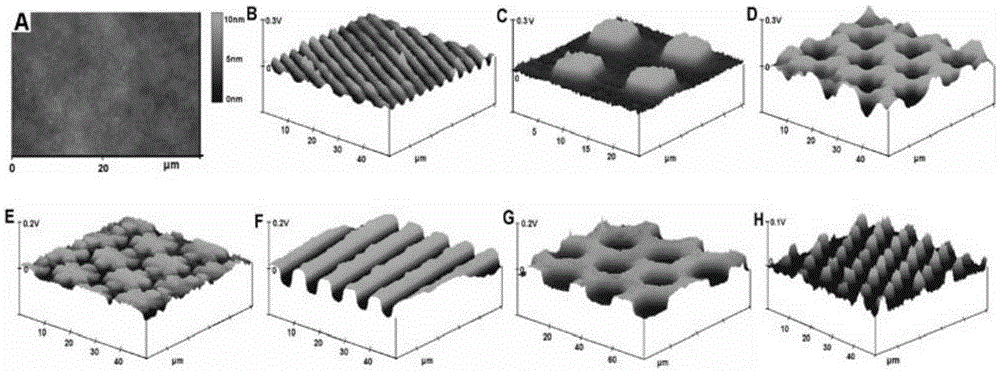

[0046] Study the relaxation phenomenon of the PMMA film (thickness is 40nm) prepared in Example 1 with patterned charge under temperature stimulation, and observe the following phenomenon: the charging time is different, and the polymer pattern has different surface potentials. Samples with different surface...

Embodiment 3

[0048] Embodiment 3, the relaxation phenomenon of PS under temperature stimulation

[0049] Since there is no hydrogen bond interaction between PS chain segments and the intermolecular force is relatively weak, PS with a small molecular weight (Mn=5,000) is also selected in this embodiment.

[0050] Study the relaxation phenomenon (i.e. the dewetting process of the surface of the PS film) of the PS film (thickness is 30nm) with the patterned charge prepared in Example 1 under temperature stimulation, and observe the following phenomenon: for smaller molecular weight, the chain segment For the shorter PS, after the polymer films charged for 5s and 30s were annealed on a hot stage at 200 °C, polymer arrays with different depths were obtained. At the same time, the higher the surface potential, the more intense the relaxation of the polymer, and the more obvious the resulting microstructure. from Image 6 It can be seen that the patterned array ( Image 6 (b)) than charging fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com