Quantum well composite LED epitaxial structure with high luminous efficiency and preparation method thereof

A technology with high luminous efficiency and multi-quantum well structure, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as low efficiency and large stress, and achieve the effects of improving device performance, reducing stress, and improving light extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

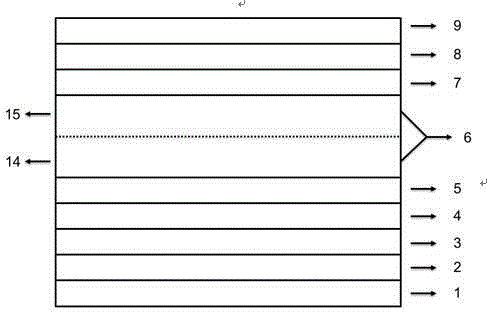

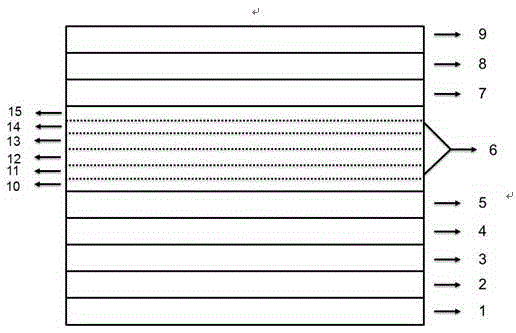

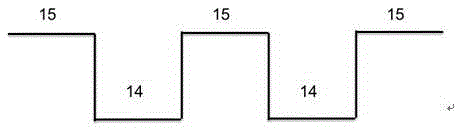

[0049] figure 2 The quantum well combination LED epitaxial structure with high luminous efficiency of the present invention is given, which can effectively reduce the stress between the well-barrier interface, alleviate the bending of the energy band, and improve the efficiency of hole and electron injection into the active region and the efficiency of radiation recombination. The epitaxial structure is substrate 1, buffer layer 2, undoped GaN layer 3, n-type AlGaN layer 4, n-type GaN layer 5, active layer 6, p-type AlGaN layer 7, p-type GaN layer from bottom to top 8 and P-type InGaN contact layer 9, with figure 1 The difference of the existing structures shown is that the active layer 6 includes a lower multi-quantum well structure, a constant temperature multi-quantum well structure and an upper multi-quantum well structure, and the lower multi-quantum well structure is an InxGa1-xN potential well layer 10 (0<x< 1) and GaN barrier layer 11 are periodically superimposed, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com