Method for culturing biofloc and method for applying biofloc to aquaculture

A technology of biological flocculation and cultivation methods, applied in the directions of microorganism-based methods, biochemical equipment and methods, biological water/sewage treatment, etc. The effect of reducing carbon source cost and bait cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for cultivating bioflocs, comprising the steps of:

[0023] 1) Select the dried wheat straw, crush the straw with a pulverizer, and then screen it with a 20-mesh screen to obtain straw particles with a particle size of less than 0.1mm;

[0024] 2) Mix the above-mentioned straw granules with cornstarch and water evenly according to the mass ratio of 10:0.5:1.5, and extrude the mixture with an extrusion extruder, control the temperature of the extrusion cavity of the extrusion extruder at 120°C, and The pulverizer crushes the expanded mixture particles into solid particles with a particle size of 0.5 mm;

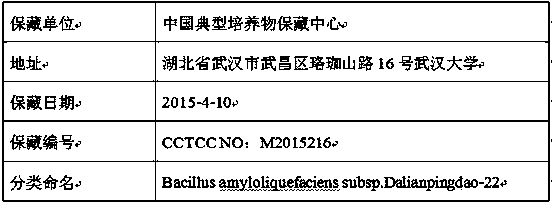

[0025] 3) Mix the above-mentioned solid particles and culture water in the culture unit according to the volume ratio of 1.1:1, and then add the bacillus named Dalianpingdao-22 and the preservation number CCTCCM2015216 into the culture unit, so that the bacillus in the culture unit The number of live bacteria is 3×10 10 cfu / L, maintain the dissolved oxygen in...

Embodiment 2

[0030] A method for cultivating bioflocs, comprising the steps of:

[0031] 1) Choose the rice straw that has been dried in the sun, crush the straw with a pulverizer, and then screen it with a 20-mesh screen to obtain straw particles with a particle size of less than 0.1mm;

[0032] 2) Mix the above-mentioned straw granules with cornstarch and water evenly according to the mass ratio of 9:0.5:1.5, and use an extruder to puff the mixture. The pulverizer crushes the expanded mixture particles into solid particles with a particle size of 0.45mm;

[0033] 3) Mix the above-mentioned solid particles and culture water in the culture unit according to the volume ratio of 1:1, and then add the bacillus named Dalianpingdao-22 and the preservation number CCTCCM2015216 into the culture unit, so that the bacillus in the culture unit The number of live bacteria is 2×10 10 cfu / L, maintain the dissolved oxygen in the water in the culture unit at 6~8mg / L, and collect bioflocs when the total...

Embodiment 3

[0038] A method for cultivating bioflocs, comprising the steps of:

[0039] 1) Choose corn stalks that have been dried in the sun, crush the stalks with a pulverizer, and then screen them with a 20-mesh sieve to obtain straw particles with a particle size of less than 0.1mm;

[0040] 2) Mix the above-mentioned straw granules with cornstarch and water evenly according to the mass ratio of 11:0.5:1.5, and extrude the mixture with an extrusion extruder, control the temperature of the extrusion cavity of the extrusion extruder at 130°C, and then The pulverizer crushes the expanded mixture particles into solid particles with a particle size of 0.55mm;

[0041] 3) Mix the above-mentioned solid particles and aquaculture water in the culture unit according to the volume ratio of 1.2:1, and then add the bacillus named Dalianpingdao-22 and the preservation number CCTCCM2015216 into the culture unit, so that the bacillus in the culture unit The number of live bacteria is 5×10 10 cfu / L,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com