Water-soluble inorganic zinc-rich primer

An inorganic zinc-rich primer technology, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of slow drying speed, peeling off, poor paint adhesion, etc., and achieve fast drying speed and comprehensive ingredients , Strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

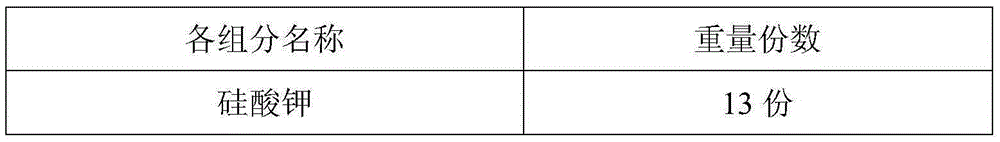

[0021] Embodiment 1 water-based inorganic zinc-rich primer, its each raw material composition component and mass percent are as follows:

[0022] Inorganic modified resin: 15%, inorganic modified zinc powder: 85%.

[0023] Wherein the raw material components and parts by weight of the inorganic modified resin are:

[0024] Component name

parts by weight

12 copies

Sodium silicate

2 copies

Aqueous silica sol

7 copies

Deionized water

6 servings

4 parts

soft lotion

5 copies

[0025] Wherein the raw material components and parts by weight of the inorganic modified zinc powder are:

[0026] Component name

Embodiment 2

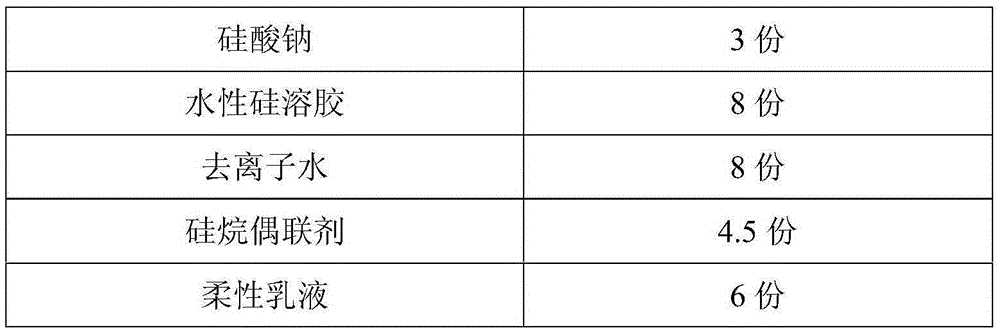

[0027] Embodiment 2 water-based inorganic zinc-rich primer, its each raw material composition component and mass percent are as follows:

[0028] Inorganic modified resin: 20%, inorganic modified zinc powder: 80%.

[0029] Wherein the raw material components and parts by weight of the inorganic modified resin are:

[0030]

[0031]

[0032] Wherein the raw material components and parts by weight of the inorganic modified zinc powder are:

[0033] Component name

Embodiment 3

[0034] Embodiment 3 water-based inorganic zinc-rich primer, its each raw material composition component and mass percent are as follows:

[0035] Inorganic modified resin: 25%, inorganic modified zinc powder: 75%.

[0036] Wherein the raw material components and parts by weight of the inorganic modified resin are:

[0037] Component name

parts by weight

Potassium silicate

14 copies

Sodium silicate

4 parts

Aqueous silica sol

9 servings

Deionized water

10 copies

5 copies

soft lotion

7 copies

[0038] Wherein the raw material components and parts by weight of the inorganic modified zinc powder are:

[0039] Component name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com