Modified polymer acids shear-enhancing agent for oil-based drilling fluids and preparation method thereof

An oil-based drilling fluid and polyacid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of increasing plastic viscosity, prone to chain scission, and improving the ratio of dynamic to plastic, so as to improve the dynamic cutting force, improve sand carrying capacity, and improve the effect of shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

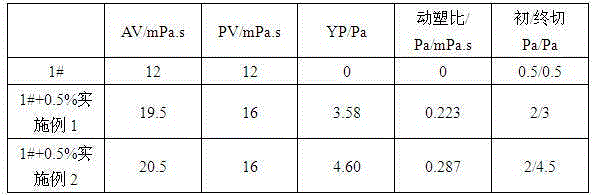

Examples

Embodiment 1

[0031] A modified polymeric acid cutting agent for oil-based drilling fluid, which is composed of the following components: polymeric acid, polyene polyamine and primary amine, wherein the combination of polymeric acid monomer and polyene polyamine monomer The molar ratio is 1.8-2:0.9-1.1, and the molar addition amount of the primary amine is the same as that of the polyene polyamine monomer.

[0032] The polymeric acid is a mixture consisting of oleic acid, linoleic acid, and dimers and trimers of oleic acid and linoleic acid, wherein the mass ratio is: 0.5% to 1% of oleic acid and linoleic acid %, trimer is 1 to 1.5%, and the balance is dimer. The ratio of oleic acid and linoleic acid is 0.5% to 1%. There is no special requirement for the ratio of oleic acid and linoleic acid, as long as it is guaranteed to contain oleic acid and linoleic acid and meet the aforementioned ratio. Among dimers and trimers, including dimers and trimers of oleic acid and dimers and trimers of li...

Embodiment 2

[0047] The invention provides a modified polymeric acid shear-lifting agent for high-temperature-resistant and high-density oil-based drilling fluid, which is formed by polycondensation of polymeric acid, polyene polyamine and primary amine through dehydration reaction, wherein the polymeric acid is a A mixture consisting of oleic acid, linoleic acid, and dimers and trimers of oleic acid and linoleic acid; polyene polyamines are ethylenediamine, diethylenetriamine, triethylenetetramine, tetraethylenepentamine One of them; the primary amine is one of propylamine, butylamine, diethylamine, isopropylamine and aniline.

[0048] The present invention also provides a preparation method of a modified polymeric acid shear-lifting agent for high-temperature-resistant and high-density oil-based drilling fluid, specifically as follows:

[0049]1. Add the polymeric acid and polyene polyamine monomer into a three-necked flask according to the molar ratio of 1.8~2:0.9~1.1, heat to 80°C in a...

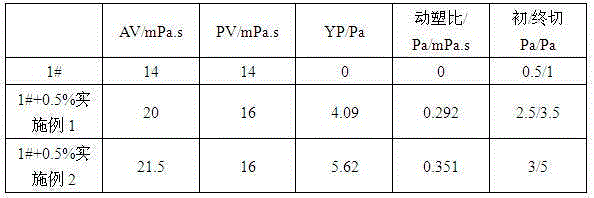

Embodiment 3

[0060] This embodiment is basically the same as the above-mentioned embodiment, the main differences are as follows:

[0061] A modified polymeric acid cutting agent for oil-based drilling fluid, which is composed of the following components: polymeric acid, polyene polyamine and primary amine, wherein the combination of polymeric acid monomer and polyene polyamine monomer The molar ratio is 1.8:0.9, and the molar addition amount of the primary amine is the same as that of the polyene polyamine monomer.

[0062] The polymeric acid is a mixture consisting of oleic acid, linoleic acid, and dimers and trimers of oleic acid and linoleic acid, wherein the mass ratio is: 0.5% of oleic acid and linoleic acid, three The polymer was 1%, and the balance was dimer.

[0063] A method for preparing a modified polymeric acid shear-lifting agent for oil-based drilling fluids, comprising: polyacid, polyene polyamine and primary amine are dehydrated and polycondensed, wherein the polymeric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com