Normal temperature slag-free phosphating solution before electrophoresis of galvanized steel sheet for automobile and preparation method thereof

A technology of galvanized steel sheet and phosphating solution, which is applied in the direction of electrophoretic plating, electrolytic coating, metal material coating technology, etc., to achieve the effects of increased adhesion, high value-added economic benefits, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

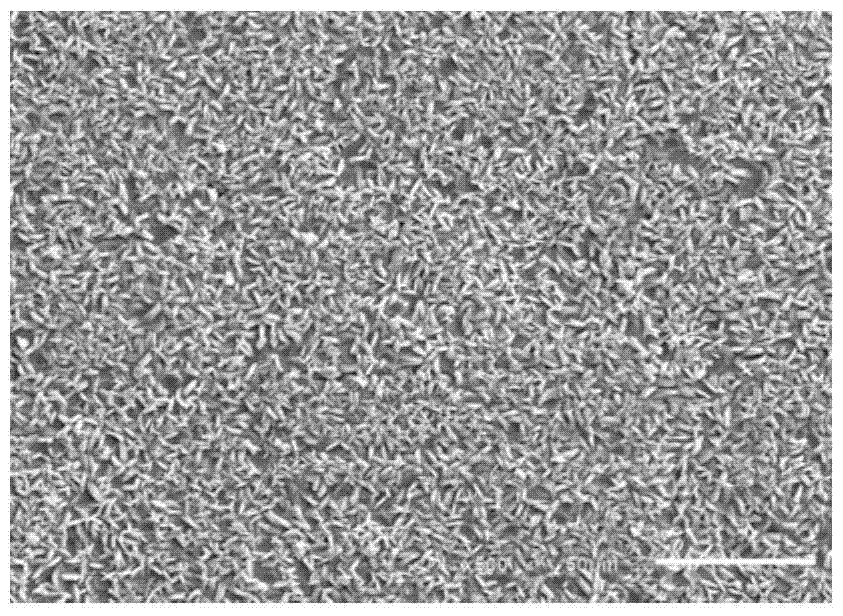

Image

Examples

Embodiment 1

[0031] Embodiment 1: The treatment liquid is calculated according to 1 L. Add water to the container at room temperature to 80%, add 1.6g of zinc oxide, start stirring until suspended, then slowly add 21.0g of phosphoric acid, stir until the solution is clear, add 9.5g of manganese nitrate solution and 3.5g of nickel nitrate, dissolve and then add 5.0g g sodium nitrate, 1.1 g hydroxylamine sulfate, 0.7 g sodium m-nitrobenzene sulfonate, 0.01 g copper nitrate, 0.2 g sodium molybdate and 1.2 g citric acid, and add another 0.4 g polyvinyl alcohol dissolved in appropriate amount of hot water. In another container, take 2.5g of fluotitanic acid solution and 0.8g of fluozirconic acid and dissolve in a solution containing an appropriate amount of hydrogen peroxide, add slowly after the above solution is completely dissolved, and continue to stir until the volume reaches 1L. A mixed solution containing sodium hydroxide and sodium carbonate is used to adjust the free acidity of the tre...

Embodiment 2

[0034]Embodiment 2: The treatment liquid is calculated according to 1 L. Add water to the container at room temperature to 80%, add 1.7g of zinc oxide, start stirring until suspended, then slowly add 22.0g of phosphoric acid, stir until the solution is clear, add 10.0g of manganese nitrate solution and 3.5g of nickel nitrate, dissolve and then add 6.0g g sodium nitrate, 1.2 g hydroxylamine sulfate, 0.8 g sodium m-nitrobenzene sulfonate, 0.02 g copper nitrate, 0.1 g sodium molybdate and 1.1 g citric acid, and add 0.3 g polyvinyl alcohol dissolved in appropriate amount of hot water. In another container, take 3.0 g of fluotitanic acid solution and 1.0 g of fluozirconic acid and dissolve in a solution containing an appropriate amount of hydrogen peroxide, add slowly after the above solution is completely dissolved, and continue to stir until the volume reaches 1 L. A mixed solution containing sodium hydroxide and sodium carbonate is used to adjust the free acidity of the treatmen...

Embodiment 3

[0037] Embodiment 3: The treatment liquid is calculated according to 1 L. Add water to the container at room temperature to 80%, add 1.8g of zinc oxide, start stirring until suspended, then slowly add 21.0g of phosphoric acid, stir until the solution is clear, add 10.5g of manganese nitrate solution and 4.0g of nickel nitrate, dissolve and then add 5.0g g sodium nitrate, 1.4 g hydroxylamine sulfate, 0.7 g sodium m-nitrobenzene sulfonate, 0.01 g copper nitrate, 0.2 g sodium molybdate and 1.3 g citric acid, and add another 0.5 g polyvinyl alcohol dissolved in appropriate amount of hot water. In another container, take 3.5 g of fluotitanic acid solution and 1.2 g of fluozirconic acid and dissolve them in a solution containing an appropriate amount of hydrogen peroxide, add slowly after the above solution is completely dissolved, continue to stir and set the volume to 1 L. A mixed solution containing sodium hydroxide and sodium carbonate is used to adjust the free acidity of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com