Porous tantalum metal bone connector and application thereof

A connector and metal bone technology, applied in the direction of bone implants, etc., to avoid stress shielding, meet the mechanical transmission of lower limbs, and facilitate the replacement of crawling growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

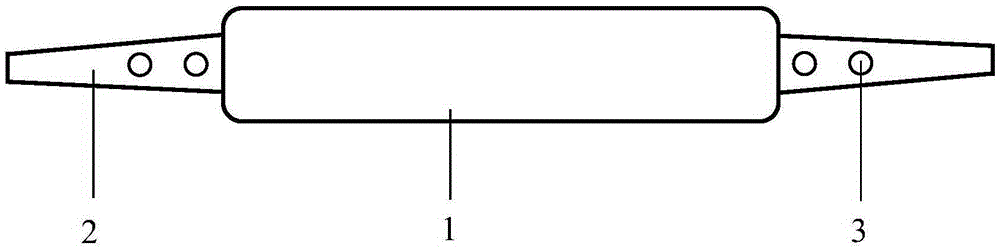

[0033] Such as figure 1 As shown, a porous tantalum metal bone connector includes a body 1, two ends of the body are respectively provided with a medullary cavity stem 2, the medullary cavity stem 2 is integrally formed with the body 1, and the medullary cavity stems 2 at both ends of the body 1 Two screw holes 3 are provided on each; the body 1 is a cylindrical solid structure, the medullary cavity stem 2 is a conical solid structure, and the diameter of the medullary cavity stem 2 gradually decreases from the part connected with the body 1 to the end, and The ratio of the diameter of the stem 2 of the medullary cavity at the connecting part of the body 1 to the diameter of the end is 2:1. Wherein, the ratio of the diameter of the medullary cavity stem 2 to the diameter of the body 1 of the connecting part with the body 1 is 1:2, and the ratio of the length of the medullary cavity stem 2 to the length of the body 1 is 1:2.

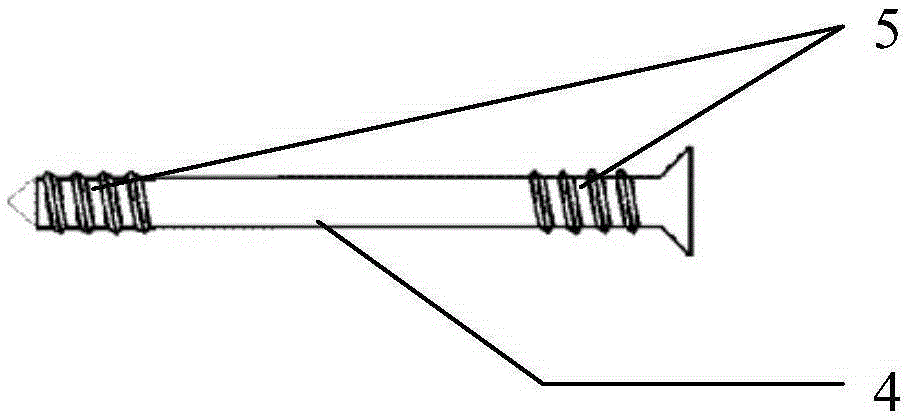

[0034] The bone connector also includes a connecting s...

Embodiment 2

[0037] The porous tantalum material used in the body 1 of the porous tantalum metal bone connector described in Example 1 is prepared by using a chemical vapor deposition method to reduce the tantalum metal compound to tantalum metal powder, and uniformly deposit on the surface of the graphite carbon skeleton to form a tantalum coating. The tantalum metal compound is tantalum pentachloride; the porosity of the graphite carbon framework is 85%, and the pore diameter is 500 μm; the thickness of the tantalum coating is 40-60 μm.

[0038] The porous tantalum bone connector is prepared by the following method:

[0039] (1) The graphitic carbon skeleton is etched with dilute hydrochloric acid for 10 minutes, washed with water and ethanol in sequence, dried with nitrogen, and placed in the reaction chamber;

[0040] (2) Put the carbon pentachloride powder with a particle size of 400 mesh into the source tank, heat it to 150°C, use high-temperature argon (300°C) as the carrier gas to pass it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com