Preparation method of anion exchange membrane capable of introducing surfactant molecules to be used as cationic sites

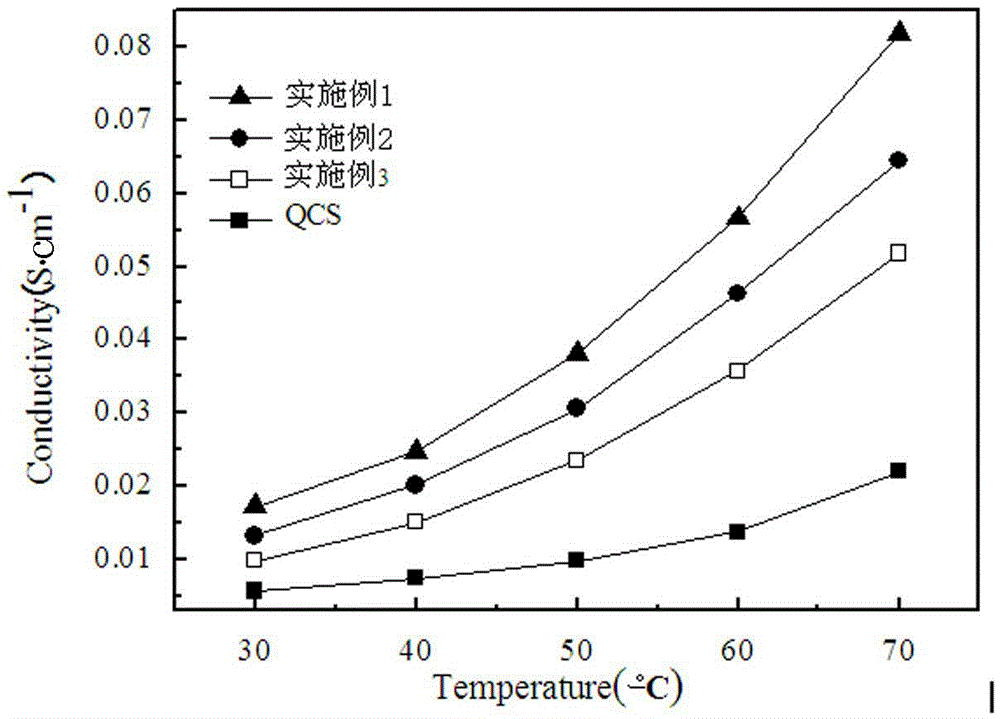

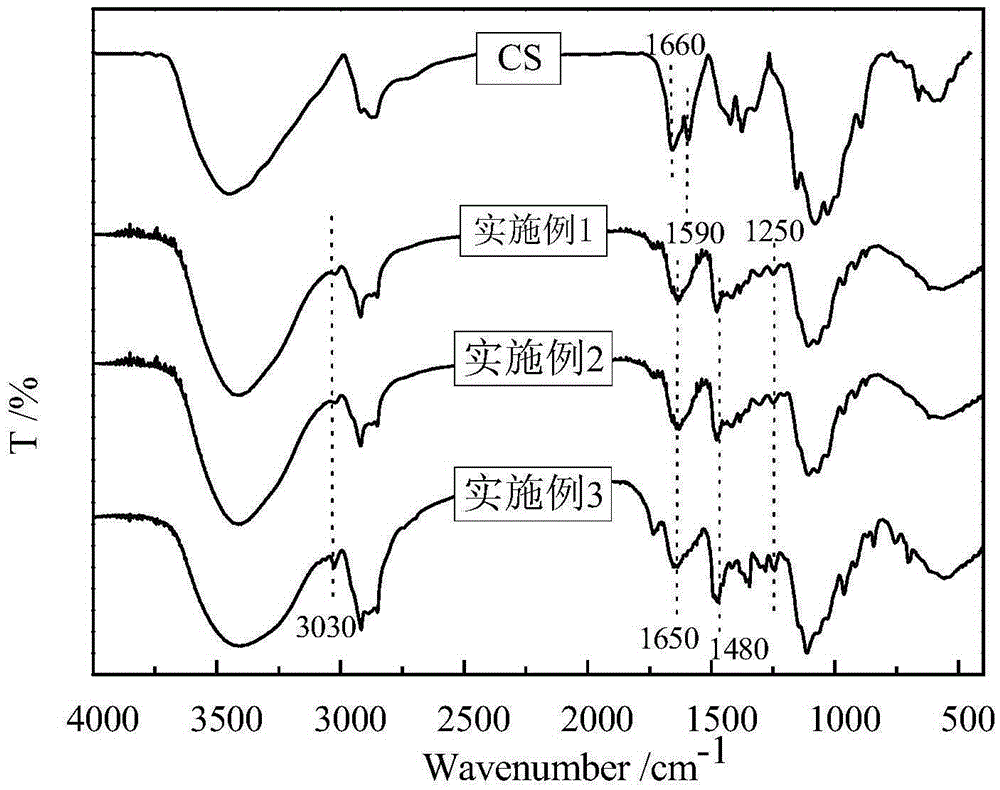

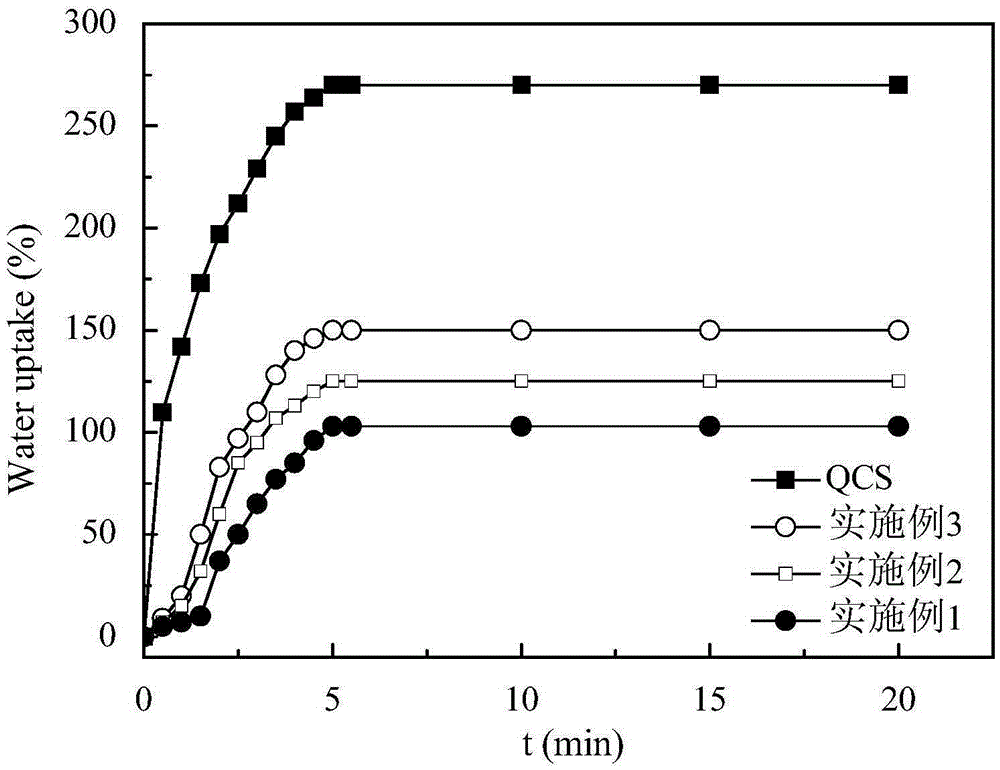

An anion exchange membrane and surfactant technology, which is applied in the field of anion exchange membranes for fuel cells to achieve the effects of improving mechanical properties, increasing electrical conductivity and reducing swelling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 4g of quaternized chitosan (QCS) with a molar ratio of quaternized ammonium substitution of 23.50%, add it to a three-necked flask containing 20mL of 2% (v / v) acetic acid solution, stir until completely dissolved, Add G with a purity of 50% 16-2-16 Molecule 2g, dissolved with 10mL 2% (v / v) acetic acid solution and added to the three-necked flask. Add the initiator KPS of 0.025g at 80 o Under the condition of C, reflux reaction for 6h, in which the initiator KPS was added three times at intervals of 1.5h, after cooling to room temperature, 2ml of glutaraldehyde solution was added, after vigorous stirring for 20min, ultrasonic oscillation for 20min, and then cast on a horizontal glass plate cast film.

[0022] (2) Immerse the membrane in 100mL deionized water, change the water every 20min, soak for 3 hours, wipe off the deionized water on the surface of the composite membrane, and place it at room temperature for 48h, slowly evaporate the water in the composit...

Embodiment 2

[0025] (1) Weigh 4g of quaternized chitosan (QCS) with a molar ratio of quaternized ammonium substitution of 23.50%, add it to a three-necked flask containing 20mL of 2% (v / v) acetic acid solution, stir until completely dissolved, Add G with a purity of 50% 12-2-12 Molecule 2g, dissolved with 10mL 2% (v / v) acetic acid solution and added to the three-necked flask. Add the initiator KPS of 0.025g at 80 o Under the condition of C, reflux reaction for 6h, in which the initiator KPS was added three times at intervals of 1.5h, after cooling to room temperature, 2ml of glutaraldehyde solution was added, after vigorous stirring for 20min, ultrasonic oscillation for 20min, and then cast on a horizontal glass plate cast film.

[0026] (2) Immerse the membrane in 100mL deionized water, change the water every 20min, soak for 3 hours, wipe off the deionized water on the surface of the composite membrane, and place it at room temperature for 48h, slowly evaporate the water in the composit...

Embodiment 3

[0029] (1) Weigh 4g of quaternized chitosan (QCS) with a molar ratio of quaternized ammonium substitution of 23.50%, add it to a three-necked flask containing 20mL of 2% (v / v) acetic acid solution, stir until completely dissolved, Adding G with a purity of 33% 8-2-8 Molecule 3.03g, dissolved with 10mL 2% (v / v) acetic acid solution and added to the three-necked flask. Add the initiator KPS of 0.025g at 80 o Under the condition of C, reflux reaction for 6h, in which the initiator KPS was added three times at intervals of 1.5h, after cooling to room temperature, 2ml of glutaraldehyde solution was added, after vigorous stirring for 20min, ultrasonic oscillation for 20min, and then cast on a horizontal glass plate cast film.

[0030] (2) Immerse the membrane in 100mL deionized water, change the water every 20min, soak for 3 hours, wipe off the deionized water on the surface of the composite membrane, and place it at room temperature for 48h, slowly evaporate the water in the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com