Battery diaphragm preparation process capable of increasing ion exchange capacity

A battery diaphragm and ion exchange technology, which is applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of reducing the quality of the diaphragm, reducing the amount of ion exchange, increasing the internal resistance of the battery, etc., to improve ion exchange The effect of improving charge and discharge efficiency and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

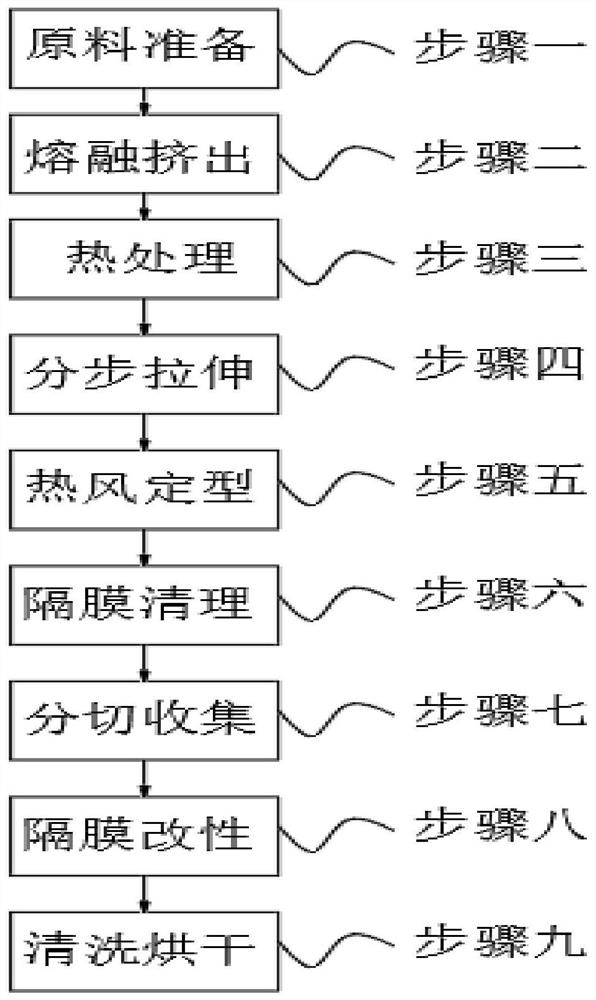

[0032] A preparation process of a battery separator for increasing ion exchange capacity, comprising the following steps: Step 1, raw material preparation; Step 2, melt extrusion; Step 3, heat treatment; Step 4, step-by-step stretching; Step 5, hot air setting; Step 6 , diaphragm cleaning; step seven, cutting and collecting; step eight, diaphragm modification; step nine, cleaning and drying;

[0033] Wherein in the above-mentioned step one, firstly, the required polypropylene and modifier are prepared, and the modifier consists of 10 parts by weight of acrylic acid, 60 parts of deionized water, 30 parts of acetone, 0.25 parts of Benzophenone, 0.05 part of lignosulfonate and 0.5 part of isomeric tridecanol polyoxyethylene ether are mixed;

[0034] In the above step two, the polypropylene prepared in step one is put into the twin-screw extruder, then the machine is turned on for heating, the polypropylene becomes molten, and then extruded from the die of the twin-screw extruder ...

Embodiment 2

[0043] A preparation process of a battery separator for increasing ion exchange capacity, comprising the following steps: Step 1, raw material preparation; Step 2, melt extrusion; Step 3, heat treatment; Step 4, step-by-step stretching; Step 5, hot air setting; Step 6 , diaphragm cleaning; step seven, cutting and collecting; step eight, diaphragm modification; step nine, cleaning and drying;

[0044] Wherein in above-mentioned step 1, at first the required polypropylene and modifying agent are prepared, modifying agent is by the weight part of 20 parts of acrylic acid, 65 parts of deionized water, 40 parts of acetone, 0.5 part of bismuth Benzophenone, 0.1 part of lignosulfonate and 0.8 part of isomeric tridecanol polyoxyethylene ether are mixed;

[0045] In the above step two, the polypropylene prepared in step one is put into the twin-screw extruder, then the machine is turned on for heating, the polypropylene becomes molten, and then extruded from the die of the twin-screw e...

Embodiment 3

[0054] A preparation process of a battery separator for increasing ion exchange capacity, comprising the following steps: Step 1, raw material preparation; Step 2, melt extrusion; Step 3, heat treatment; Step 4, step-by-step stretching; Step 5, hot air setting; Step 6 , diaphragm cleaning; step seven, cutting and collecting; step eight, diaphragm modification; step nine, cleaning and drying;

[0055] Wherein in the above-mentioned step one, firstly, the required polypropylene and modifier are prepared, and the modifier consists of 15 parts by weight of acrylic acid, 62 parts of deionized water, 35 parts of acetone, 0.45 parts of Benzophenone, 0.6 part of lignosulfonate and 0.75 part of isomeric tridecanol polyoxyethylene ether are mixed;

[0056] In the above step two, the polypropylene prepared in step one is put into the twin-screw extruder, then the machine is turned on for heating, the polypropylene becomes molten, and then extruded from the die of the twin-screw extruder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com