Inorganic silica gel chelating ion exchange resin and preparation method thereof

A technology of chelating ions and exchange resins, which is applied in the direction of chelate ion exchange, ion exchange, chemical instruments and methods, etc. It can solve the problems of weak metal chemical bonding, low mechanical properties, poor thermal stability, etc., and achieve oxidation resistance Effects of mechanical and physical properties, fast exchange rate, and strong hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

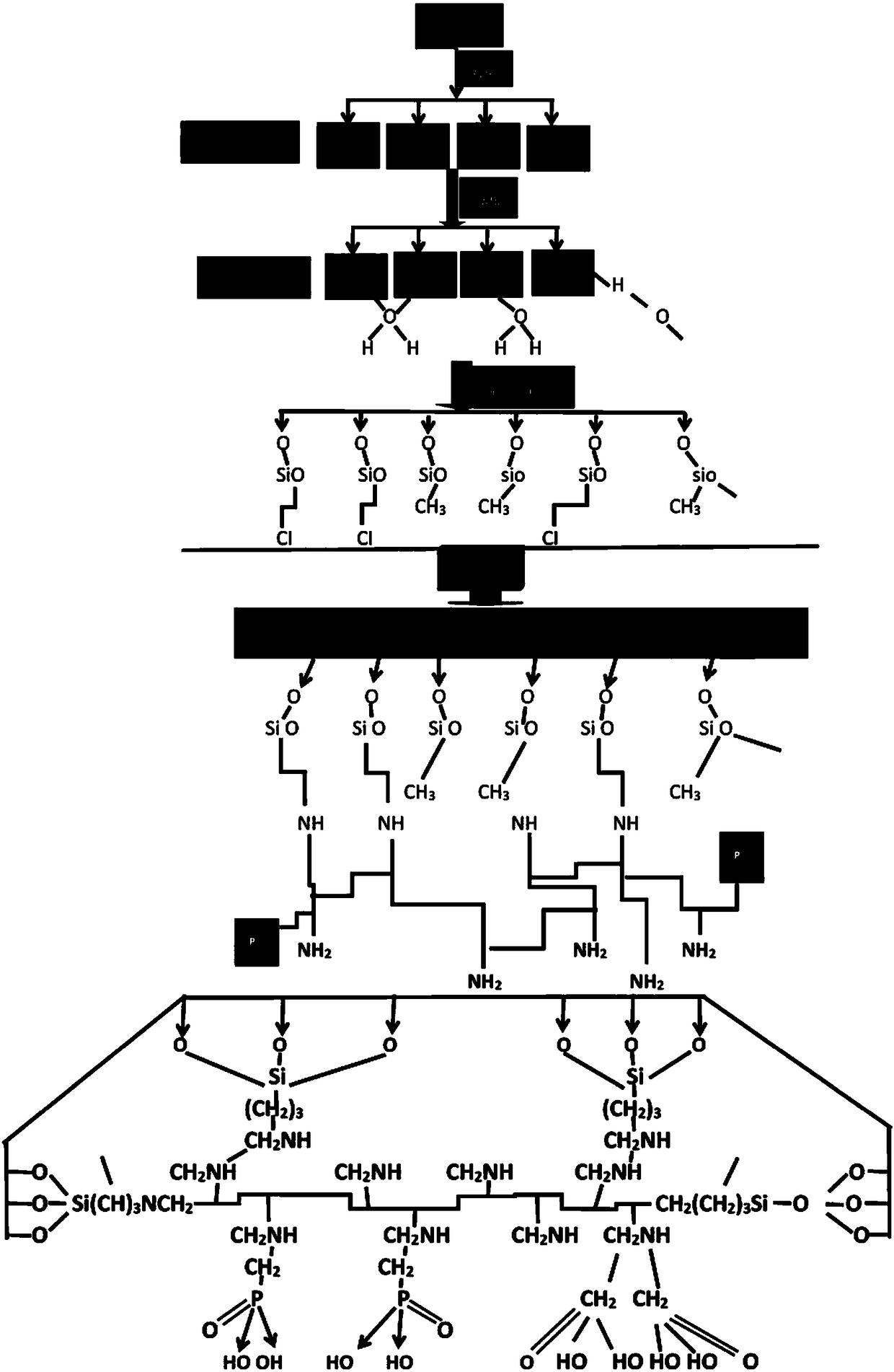

[0041] Such as figure 1 As shown, add 10kg of silica gel matrix into a corrosion-resistant reaction kettle equipped with a stirrer, then add 60L, 1M HCl, after vacuuming for 10min, the vacuum degree is 30mmHg, start heating and boiling (100°C), and the stirring speed should not be too fast , controlled at 70 rpm, so as not to damage the silicone. Stir and pickle at a bubble point temperature of 100°C for 14 hours, then pass cooling water to cool down, and release the silica gel matrix when the material temperature drops to room temperature. The released silica gel matrix is filtered to remove the filtrate, and then washed with deionized water, and the washing is stopped when the washing water shows neutrality, and the silica gel matrix and water are separated, and then the silica gel matrix is dried to constant weight to obtain the acid-washed and dried to constant weight of the pretreated silica substrate.

[0042] Put the silica gel matrix that has been pickled and dri...

Embodiment 2

[0047] Such as figure 1 As shown, add 10 kg of silica gel matrix into a reaction kettle equipped with corrosion resistance, and then add 60L, 1M HNO 3 , after evacuating for 20 minutes, the vacuum degree is 40mmHg, start heating to 90°C, the stirring speed should not be too fast, control it at 75 rpm, so as not to damage the silica gel. Stir and pickle at a bubble point temperature of 90°C for 6-18 hours, then pass cooling water to cool down, and filter to obtain the acidified silica gel matrix when the material temperature drops to room temperature, and then wash with deionized water until it shows neutrality. Stop washing , and then dried to constant weight, to obtain the pretreated silica gel matrix.

[0048] Put the silica gel matrix that has been pickled and dried to constant weight on the sand funnel, let the humid air of potassium bromide saturated solution enter the sand funnel through the rubber tube, so that a monolayer of water molecules is formed on the surface of...

Embodiment 3

[0067] The chelating resin prepared by embodiment 1 and embodiment 2 is carried out the adsorption verification of nickel respectively.

[0068] The method is: put the chelating resin into the resin column respectively, and the column volume is 1m 3 , then use 25% sulfuric acid solution to wash the resin, and then rinse the resin to pH5 with water, and the laterite-nickel ore pickling solution (stock solution) is adsorbed through the column.

[0069] Table 1 Ferronickel content in the stock solution of laterite nickel ore acid leaching solution

[0070] serial number

Nickel (g / L)

Iron (g / L)

Velocity (m 3 / h)

1

0.7984

13.4

1.9

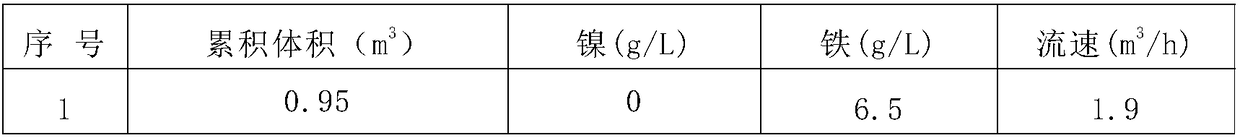

[0071] Use the chelating resin that embodiment 1 prepares to have the relationship between nickel-iron adsorption amount and volume in the adsorption process as shown in table 2:

[0072]

[0073]

[0074] Take water as the record of the chelating resin prepared by cleaning solution cleaning emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com