A method for identification of recycled polyester by chemical recycling method

A technology of chemical recycling and regeneration of polyester, applied in scientific instruments, biological neural network models, measuring devices, etc., can solve the problem that organic impurities cannot be completely removed, and achieve the effect of easy implementation and strong nonlinear mapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

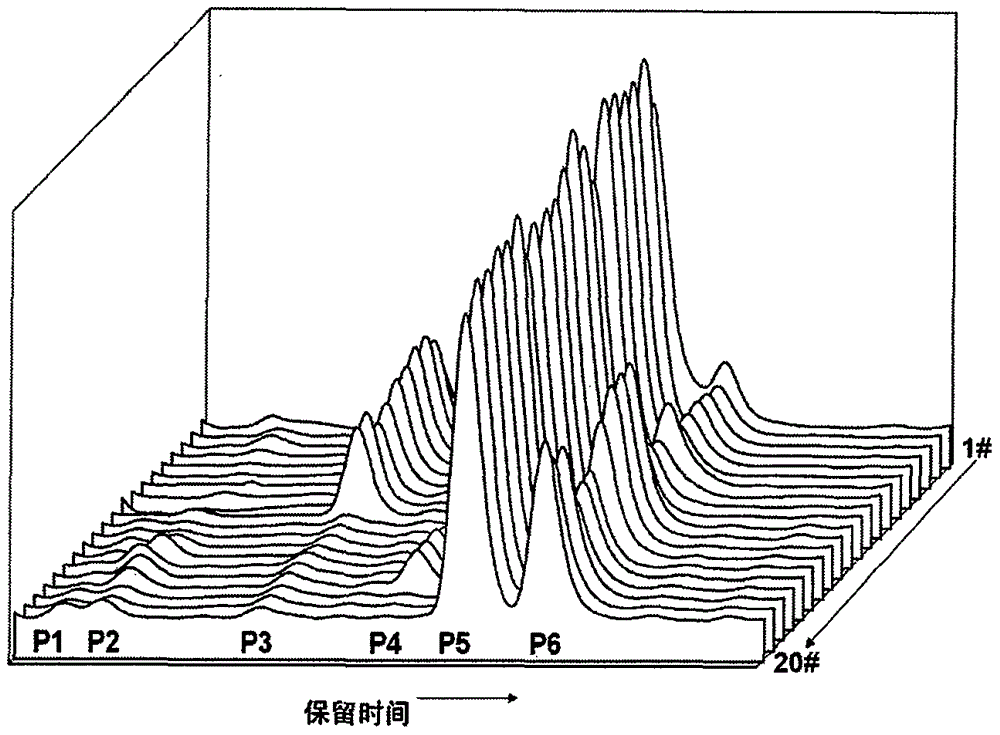

[0047] 10 virgin polyester fiber samples, provided by domestic virgin polyester fiber manufacturers, sample numbers are 1#~10#; 10 recycled polyester fiber samples, provided by domestic and foreign chemical recycled polyester fiber manufacturers, sample numbers are 11#~ 20#.

[0048] Step 1. Extract the alcoholysis of trace organic impurities embedded in the polyester macromolecular structure

[0049] The alcoholysis of organic impurities embedded in the polyester macromolecular structure is extracted by methanolysis method. The specific steps are as follows: prepare a methanol solution with a zinc acetate concentration of 0.02mg / mL as the transesterification solution, and mix 1g of polyester fiber with 30mL of the transesterification solution Put it in a reaction tube, seal it and put it in a heating device, react at 215°C for 3 hours, take out the reaction tube, cool to room temperature and filter, remove the precipitated filtrate containing the extracted polyester macromole...

Embodiment 2

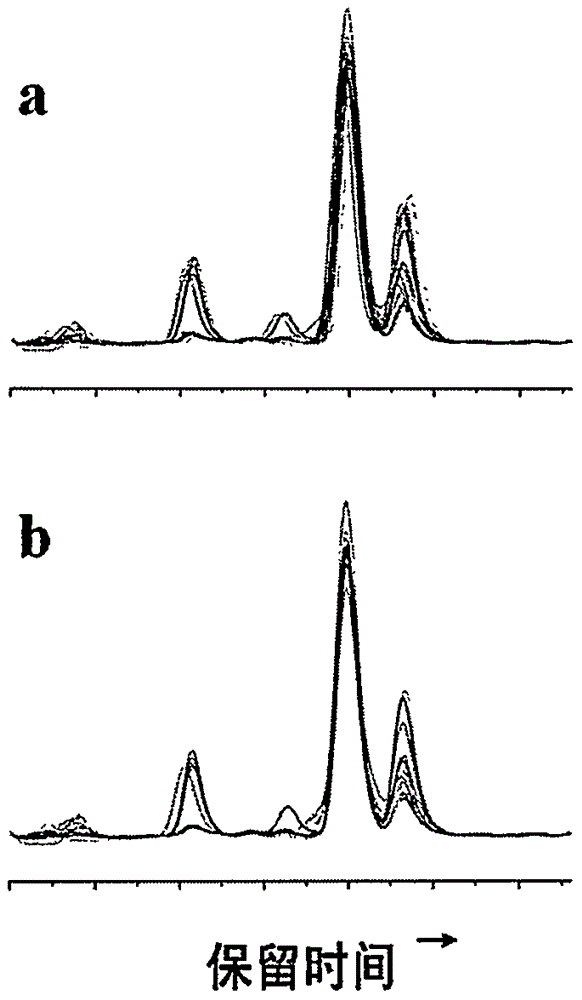

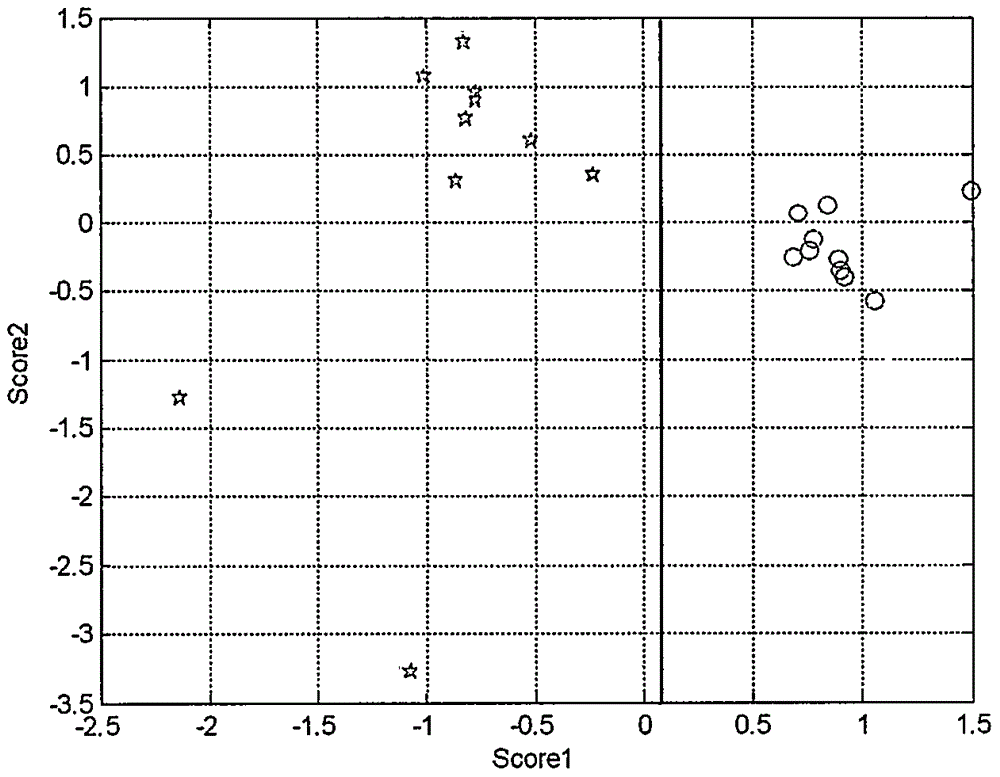

[0145] For the sample in Example 1, the step of extracting the organic impurity alcoholyzate embedded in the polyester macromolecular structure is: preparing a methanol solution with a concentration of zinc acetate of 0.04 mg / mL as a transesterification solution, mixing 1.5 g of polyester fiber and Put 50mL of the transesterification solution in a reaction tube, seal it and put it into a heating device, react at 225°C for 3.5 hours, take out the reaction tube, cool to room temperature and filter, remove the precipitated filtrate containing the extracted intercalated polyester The alcoholysis of organic impurities in the macromolecular structure. The preprocessing method for the variable matrix data is: according to this, the variable matrix is treated with area normalization and the first-order numerical differential matrix. Perform principal component analysis on the first-order differential matrix, and combine the first and second principal component scores of the first-or...

Embodiment 3

[0153] For the sample in Example 1, the step of extracting the alcoholyzate of organic impurities embedded in the polyester macromolecular structure is: preparing a methanol solution with a concentration of zinc acetate of 0.02 mg / mL as a transesterification solution, mixing 1 g of polyester fiber and 30 mL Put the transesterification solution in a reaction tube, seal it and put it into a heating device, take out the reaction tube after reacting at 215°C for 2.5 hours, cool to room temperature and filter, remove the precipitated filtrate containing the extracted Alcoholysis of organic impurities in the molecular structure. The method of preprocessing the variable matrix data is as follows: the variable matrix is preprocessed by area normalization. Principal component analysis is performed on the preprocessed matrix data, and the first, second and third principal component scores of the preprocessed matrix data are combined into a new feature matrix, and the three column vect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com