Partially degradable blood vessel stent and preparation method thereof

A vascular stent and mass percentage technology, which is applied in the field of partially degradable vascular stents and their preparation, can solve the problems of weak radial support force of magnesium alloy stents and poor light transmittance of stents, and achieve the effect of avoiding easy breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

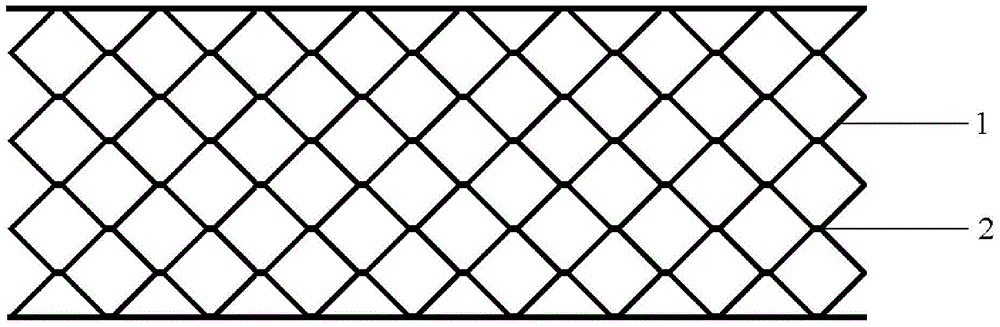

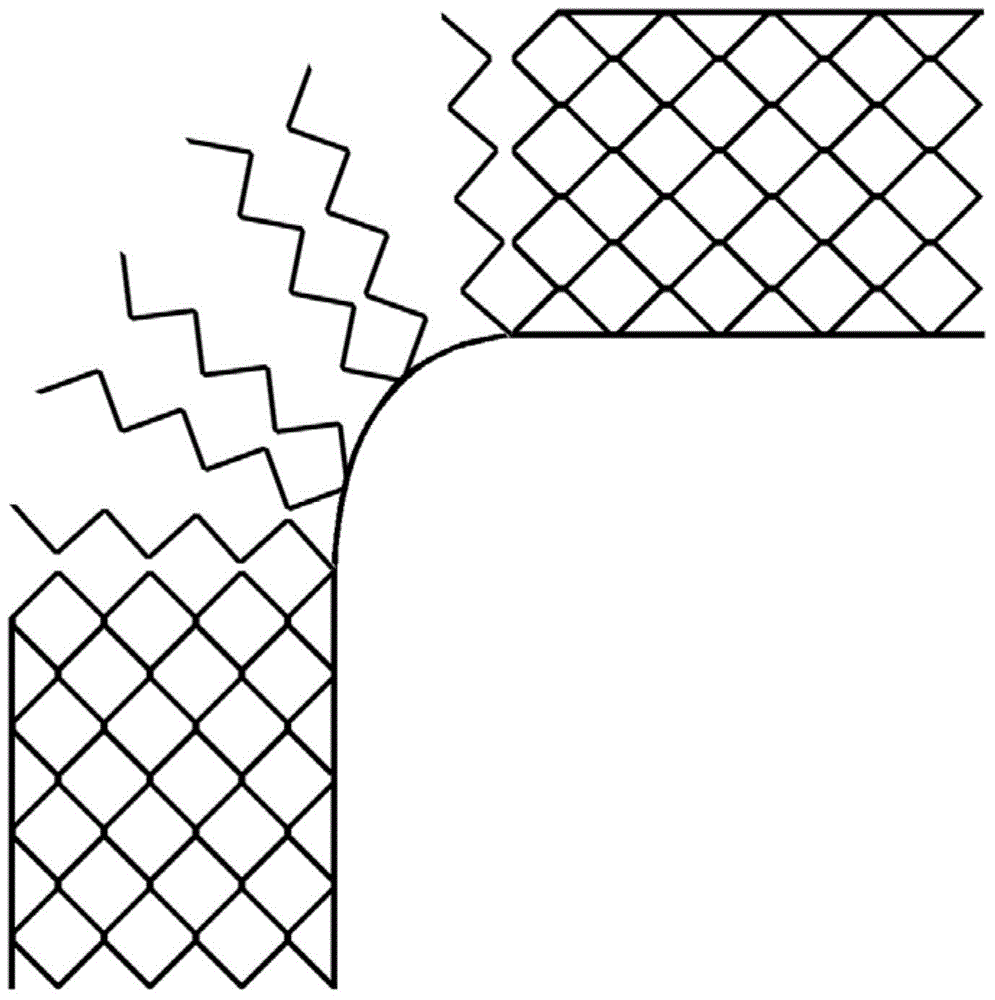

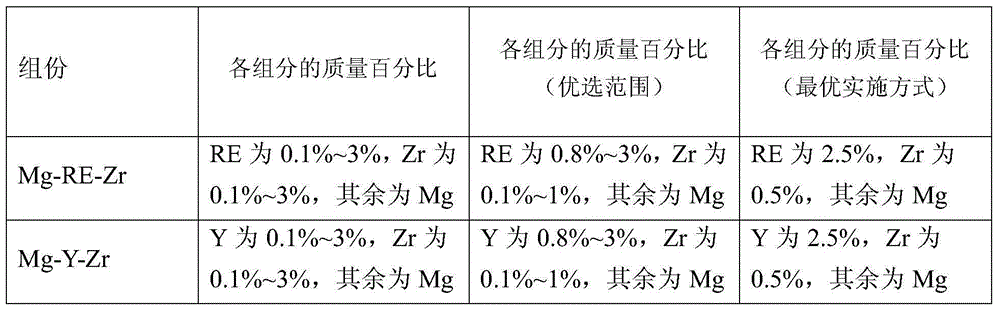

[0061] Such as figure 1 , figure 2 As shown, a partially degradable vascular stent is composed of single rings, and the single rings are connected to each other through connection points. The material of the single rings is a non-degradable metal material, and the connection points are made of degradable The magnesium alloy material, the composition and ratio of the magnesium alloy material are shown in Table 1.

[0062] Table 1: each component of the present invention and proportioning thereof

[0063]

[0064]

[0065]

Embodiment 2

[0067] A method for preparing a partially degradable vascular stent, the method comprising the following steps:

[0068] 1) Carry out stress relief annealing treatment with the magnesium alloy extruded rod of the proportioning in Table 1 as mentioned above;

[0069] 2) Machining the annealed bar into a tube blank and extruding;

[0070] 3) performing stress relief annealing on the extruded capillary;

[0071] 4) Laser cutting the annealed capillary into a stent blank;

[0072] 5) In order to remove the cutting residue, the cut and formed bracket is pickled and ultrasonically cleaned in an ultrasonic cleaning machine; pickling refers to: 5-30min, the pickling liquid formula is phosphoric acid 80-100ml / L, ammonium bifluoride 40-60g / L, the solvent is deionized water. Ultrasonic cleaning means: the acid-washed stent is ultrasonically cleaned with deionized water and absolute ethanol for 5-10 minutes respectively.

[0073] 6) Electrochemical polishing, ultrasonic cleaning and ...

Embodiment 3

[0075] A method for preparing a partially degradable vascular stent, the method comprising the following steps:

[0076] Step 1. According to the shape and size requirements of the inner cavity of the aluminum alloy waveguide, a soluble core is prepared from a soluble material;

[0077] Step 2, install the soluble core on the core support of the four-axis motion platform, and control the movement of the soluble core according to the preset trajectory through the X-axis, Y-axis, Z-axis and R-axis of the motion platform;

[0078] Step 3. After removing the oxide skin of the aluminum alloy billet, place it in the crucible, and fill the inert gas in the spray environment to ensure that the oxygen content in the low-oxygen environment is lower than 1PPM;

[0079] Step 4: Start the system heating program, and gradually heat the crucible to 100-150°C above the liquidus line of the aluminum alloy through the induction heater;

[0080] Step 5, measure the temperature of the crucible 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com