Columnar activated carbon, preparation method thereof as well as carrier of ruthenium-based ammonia synthesis catalyst

A technology of activated carbon and activator, applied in the field of activated carbon, can solve problems such as difficulty in preparing columnar activated carbon, and achieve the effects of high strength, good synergy and expanding application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

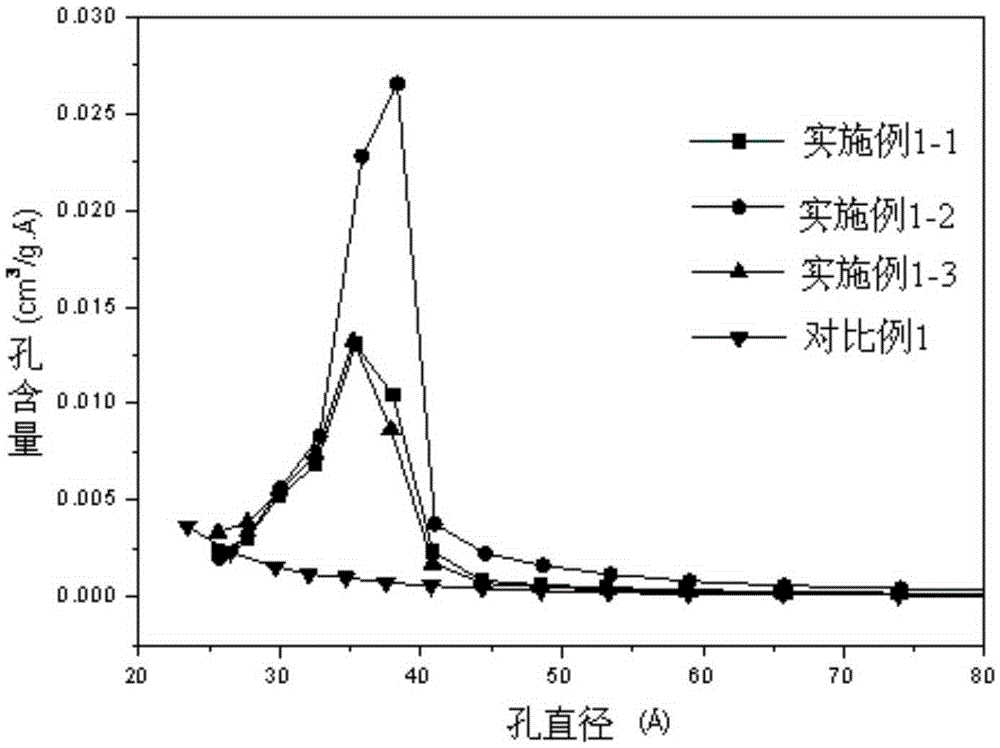

Embodiment 1-1

[0039] The clean coconut shell is dried and crushed, crossed a 100 mesh sieve, then gets 50g of coconut shell powder, adds 1.5g of field greens powder, mixes evenly, adds mixed solution (44g mass fraction is the phosphoric acid of 85%, 2.5gKH 2 PO 4 , 15g water), placed in a kneader and kneaded for 40min;

[0040]Then take it out and dry it in a vacuum drying oven at 40°C for 20 minutes, then extrude and shape it. The molding material is placed in a drying oven at 120°C for pre-curing for 3 hours, and then the material is placed in an atmosphere furnace for carbonization and activation. The process parameters are: argon Atmosphere, the flow rate is controlled at 100ml / min, the heating rate is 5°C / min, the final temperature is set at 800°C, and maintained for 1h;

[0041] When the temperature drops to room temperature, take it out, rinse it with water until the pH value is 6, and dry it.

Embodiment 1-2

[0043] The clean coconut shell is dried and broken, crossed 100 mesh sieve, then get 50g coconut shell powder, add 1.5g scallop powder, mix well, add mixed solution (44g mass fraction is phosphoric acid of 85%, 2.5gK 2 HPO 4 , 15g water), placed in a kneader and kneaded for 30min;

[0044] Then take it out and dry it in a vacuum drying oven at 50°C for 30 minutes, then extrude and shape it. The molding material is placed in a drying oven at 110°C for pre-curing for 3 hours, and then the material is placed in an atmosphere furnace for carbonization and activation, in an argon atmosphere, and the flow rate is controlled as 100ml / min, the heating rate is 5°C / min, the final temperature is set at 800°C, and maintained for 1h;

[0045] When the temperature drops to room temperature, take it out, rinse it with water until the pH value is 6, and dry it.

Embodiment 1-3

[0047] The clean coconut shell is dried and broken, crossed a 100-mesh sieve, then gets 50g of coconut shell powder, adds 1.5g of field turnip powder, mixes evenly, adds mixed solution (44g mass fraction is phosphoric acid of 85%, 2.5gKNO 3 , 15g water), placed in a kneader and kneaded for 40min;

[0048] Then take it out and dry it in a vacuum drying oven at 40°C for 20 minutes, then extrude and shape it. The molding material is placed in a drying oven at 120°C for pre-curing for 3 hours, and then the material is placed in an atmosphere furnace for carbonization and activation. The process parameters are: argon Atmosphere, the flow rate is controlled at 100ml / min, the heating rate is 5°C / min, the final temperature is set at 800°C, and maintained for 1h;

[0049] When the temperature drops to room temperature, take it out, rinse it with water until the pH value is 6, and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com