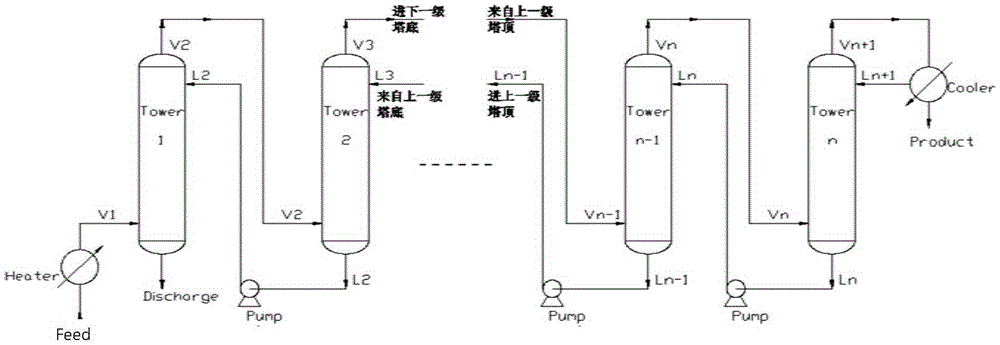

Multi-stage series continuous rectification separation apparatus for light hydrogen molecular water and method

A technology for the separation of light hydrogen molecular water and rectification, which is applied in the field of stable isotope separation, can solve the problems of restricting the market and application of stable isotope products, the inability to couple and utilize heat, and the small isotope separation coefficient, so as to simplify the structure and shorten the equilibrium time , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

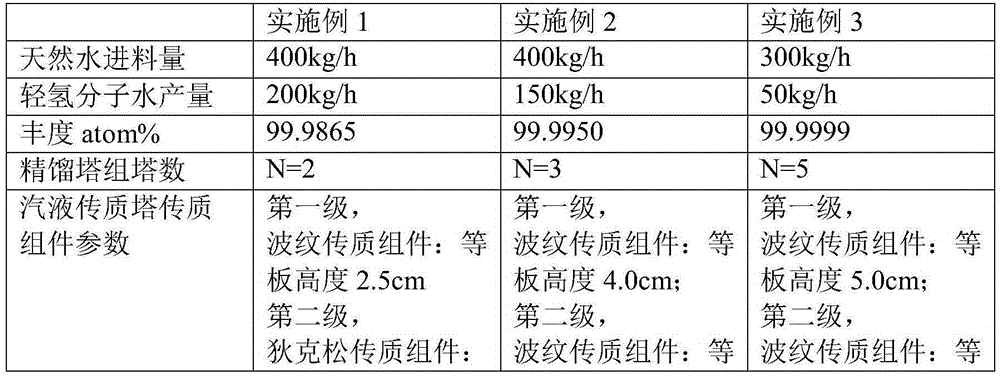

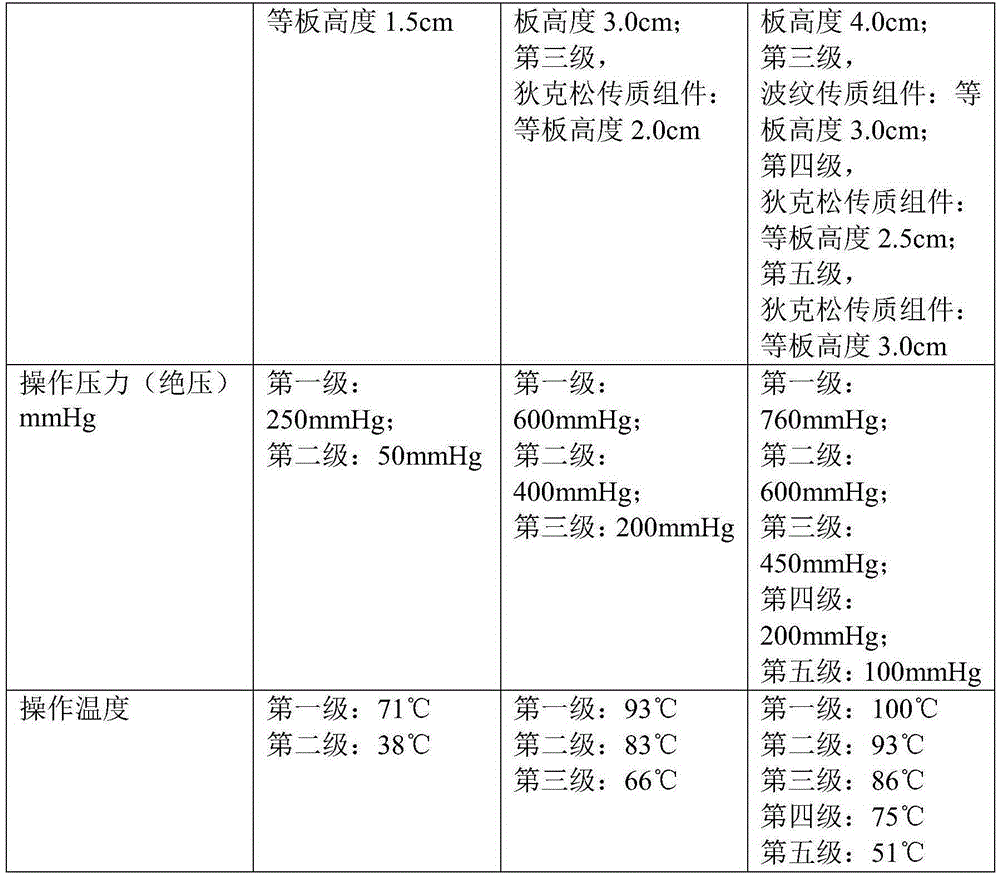

Embodiment 1

[0049] Natural water is used as the raw material, and the abundance of light hydrogen isotopes in the raw water is 99.985%. The device for the continuous rectification and separation of light hydrogen molecular water by multi-stage series series is composed of two-stage vapor-liquid mass transfer rectification towers connected in series. The first stage rectification tower is filled with corrugated regular mass transfer components. Absolute pressure), the operating temperature is 71°C; the second-stage rectification column is filled with Dick's loose stack mass transfer components, the plate height is 1.5cm, the operating pressure is 50mmHg (absolute pressure), and the operating temperature is 38°C. After the natural water raw material is vaporized by the vaporizer, it enters the two-stage series rectification column group, and the vapor phase material and the liquid phase material on the mass transfer components filled in the rectification tower are fully contacted, and partia...

Embodiment 2

[0051] Natural water is used as the raw material, and the abundance of light hydrogen isotopes in the raw water is 99.985%. The device for multi-stage serial continuous rectification and separation of light hydrogen molecular water is composed of three-stage vapor-liquid mass transfer rectification towers connected in series. The first stage rectification tower is filled with corrugated regular mass transfer components. The equal plate height is 4.0cm, and the operating pressure is 600mmHg ( Absolute pressure), operating temperature 93°C; the second-stage rectification column is filled with corrugated regular mass transfer components, the plate height is 3.0cm, the operating pressure is 400mmHg (absolute pressure), and the operating temperature is 83°C; the third-stage rectification column is filled with Dick Loose stack mass transfer components, equal plate height 2.0cm, operating pressure 200mmHg (absolute pressure), operating temperature 66°C. After the natural water raw ma...

Embodiment 3

[0053] Natural water is used as the raw material, and the abundance of light hydrogen isotopes in the raw water is 99.985%. The device for multi-stage serial continuous rectification and separation of light hydrogen molecular water is composed of five stages of vapor-liquid mass transfer rectification towers connected in series. The first stage rectification tower is filled with corrugated regular mass transfer components, the height of the plate is 5.0cm, and the operating pressure is 760mmHg ( Absolute pressure), the operating temperature is 100°C; the second-stage rectification tower is filled with regular corrugated mass transfer components, the plate height is 4.0cm, the operating pressure is 600mmHg (absolute pressure), and the operating temperature is 93°C; the third-stage rectification tower is packed with regular corrugated components Mass transfer components, equal plate height 3.0cm, operating pressure 450mmHg (absolute pressure), operating temperature 86°C; the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com