Waste acid recovery apparatus

A technology of acid recovery and equipment, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of inability to serve small and medium-sized enterprises by vehicle, waste acid recycling equipment occupying an area Problems such as large area and inability to expand functions have achieved the effect of improving processing effect, easy error checking, and reducing the amount of fresh acid used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

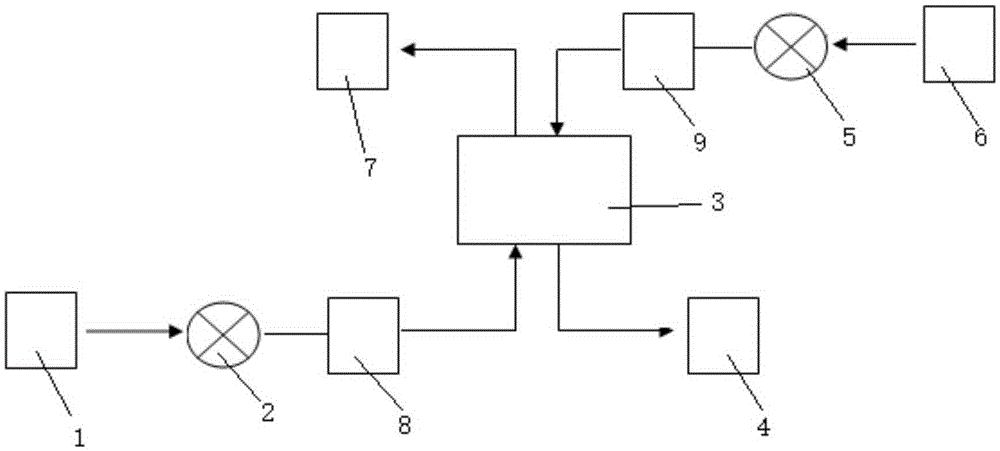

Method used

Image

Examples

specific Embodiment approach 1

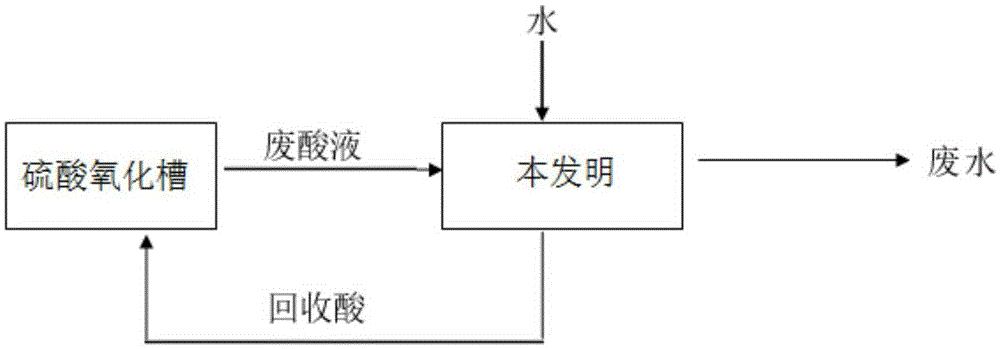

[0031] One of the procedures in the aluminum anode treatment process in the surface treatment industry is oxidation. The aluminum raw material is immersed in a 200-250g / L sulfuric acid tank, and the surface of the aluminum material is treated by using the sulfuric acid etching and oxidation ability before proceeding to the next procedure. After the first treatment, the aluminum of the aluminum material will dissolve into the sulfuric acid. When the concentration of aluminum ions is 7-10g / L, the bath needs to be replaced. Such as figure 2 As shown, the tank liquid to be replaced is passed through the present invention to separate the sulfuric acid from the aluminum ions, and the recovered acid can continue to be used after re-adding high-concentration sulfuric acid. In the process of use, the sulfuric acid oxidation tank is used as the waste acid tank, and the H 2 SO 4 Be 200g / L, AL is the waste acid liquid of 10g / L through the present invention, passes into appropriate amou...

specific Embodiment approach 2

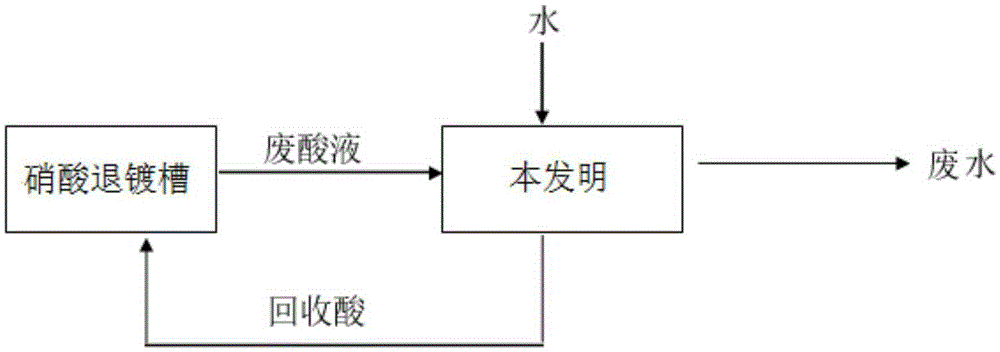

[0032] Such as image 3 As shown, the electroplating industry generally uses nitric acid as the stripping solution, especially for stripping nickel metal, in order to obtain fast stripping when dealing with stripped products. In the process of actual production work, enterprises only require high processing capacity, and the requirements for both the concentration of recovered acid and the concentration of metal ions in discharged wastewater are not high. In the process of use, the nitric acid deplating tank is used as the waste acid tank, and the HNO 3 It is 340g / L, Ni is the waste acid liquid of 18g / L through the present invention, feeds appropriate amount of water in the present invention, HNO 3 264g / L, Ni is 12.8g / L recovery acid and then returns to the nitric acid strip tank, HNO 3 The waste water with 8g / L and 4.3g / L Ni will be discharged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com