Unipolar water magnetizing and activating method and device

A magnetization device and a technology for activating water, which are applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as insufficient magnetization, unreasonable structure, and limited utilization of far-infrared rays by minerals. Achieve strong adsorption and water purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The two-step process of unipolar magnetization and ore activation is used to prepare activated water suitable for individual household drinking. The specific method is:

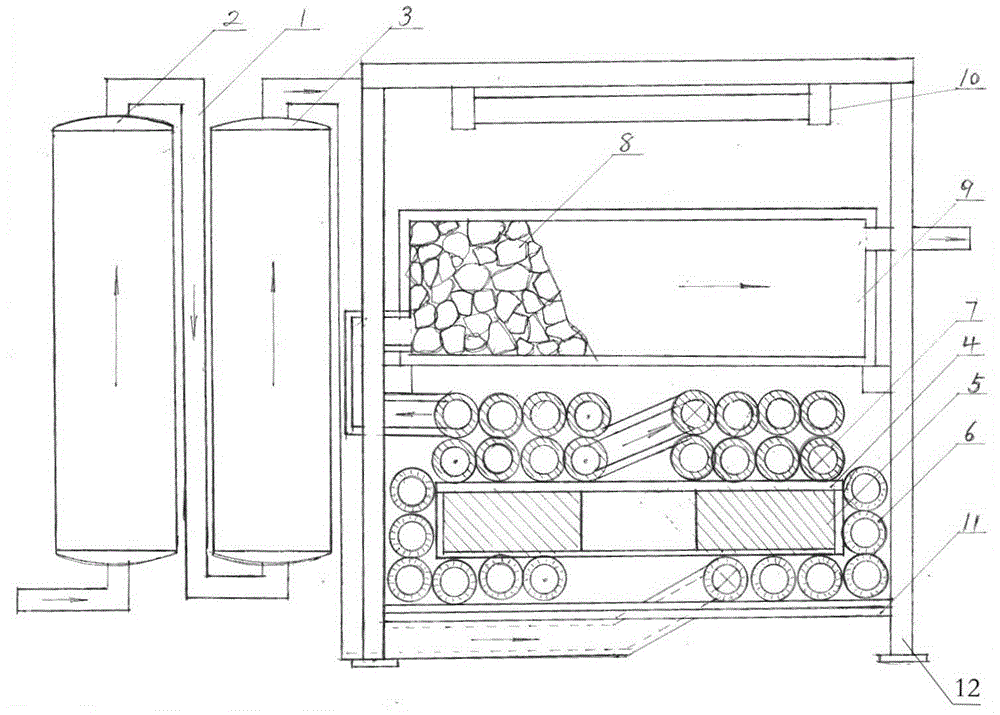

[0026] The unipolar magnetization process is to use a permanent magnetic disk 5 with a diameter of 120mm and a thickness of 12mm made of N45 NdFeB, and use its surface average magnetic induction of 5000 Gauss to perform S pole magnetic field line cutting on the main disk tube 7 and its water flow , and use the magnetic tube 6 below and side of the permanent magnetic disk 5 to pre-magnetize its water flow with a magnetic field close to the N pole. The 18-turn main disc tube 7 made of silica gel with the same internal diameter is connected into a water circuit and then in the activation container 9, under the magnetic isolation and the turning of the magnetic force line of the magnetic isolation plate 11 made of copper plate, the permanent magnetic disc 5 is originally formed on the plane of its center of...

Embodiment 2

[0029] The four-step process of pre-filtration, post-filtration, monopolar magnetization, and ore activation is used to complete the production process suitable for household activated water.

[0030] Described pre-filter process is to be 100mm with internal diameter, and its lower end is provided with water inlet, and the upper end is provided with the plastic pre-filter device 2 that two water pipes are connected in series, and filter sand material wherein adopts zeolite of 4-40 mesh, Three minerals, garnet and rutile, and activated carbon particles are similar in quality, and the mass ratio of the total mineral mass to activated carbon is 4:1, and they are randomly combined into two groups, which are filled in two pre-filter devices 2, The ratio of the total mass of the four kinds of particles (filter sand materials) to the water output per minute of the pre-filter device is 1:2, and the water inflow of the pre-filter device is connected to tap water.

[0031] The post-filt...

Embodiment 3

[0035] The four-step process of pre-filtering, post-filtering, unipolar magnetization and ore activation is used to produce magnetized activated water suitable for drinking by 20-40 households. The specific process is as follows:

[0036] The pre-filtering process is made of zeolite, actinolite, medical stone three minerals and activated carbon particles 4-40 mesh The amount of zeolite is not less than 1 / 10 of the total mass of minerals, and the mass ratio of minerals and activated carbon is 10:1. The zeolite and activated carbon are mixed and installed in the first pre-filter device for summarization. In the second pre-filter device, the ratio of the total mass of filter sand to the water output per minute of the corresponding pre-filter device is 6:2.

[0037] The post-stage filtration process is to select four kinds of meteorites, skarn, serpentine jade and tourmaline from 12 kinds of energy ores and crush them into coarse sand with a particle size of 3-10mm. The quality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com