Microwave dielectric ceramic with low dielectric constant and low loss and preparation method

A technology of microwave dielectric ceramics and low dielectric constant, applied in the field of dielectric ceramics and its manufacturing, can solve the problems of high loss, unstable temperature coefficient, high dielectric constant, etc., achieve low dielectric loss, good environmental performance, low dielectric constant The effect of the electric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention provides a microwave dielectric ceramic with low dielectric constant and low loss. The main crystal phase structure formula of the microwave dielectric ceramic is: xZnO-yMgO-zB 2 o 3 , where x=1, y=0.2, z=3, and the raw materials of the main crystal phase of the microwave dielectric ceramic are: ZnO, MgO and H 3 BO 3 , the microwave dielectric ceramic also includes SiO with a mass fraction of 20%, 1% and 10% respectively 2 、TiO 2 and Al 2 o 3 .

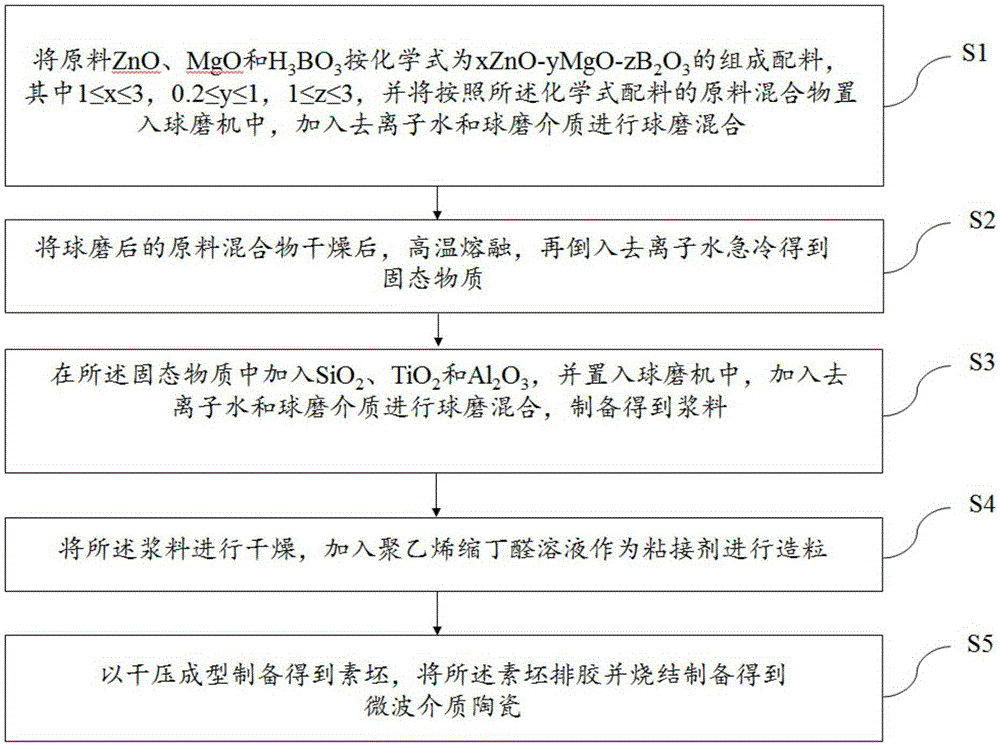

[0038] Correspondingly, the present invention also provides a low dielectric constant, low loss microwave dielectric ceramic preparation method, comprising the following steps:

[0039] S1, the raw materials ZnO, MgO and H 3 BO 3 According to the chemical formula xZnO-yMgO-zB 2 o 3 The composition batching, wherein x=1, y=0.2, z=3, and put the raw material mixture according to the chemical formula batching into a ball mill, add deionized water and zirconia balls with a diameter of 2mm and ball mill at a ...

Embodiment 2

[0045] The invention provides a microwave dielectric ceramic with low dielectric constant and low loss. The main crystal phase structure formula of the microwave dielectric ceramic is: xZnO-yMgO-zB 2 o 3 , where x=2, y=1, z=2, and the raw materials of the main crystal phase of the microwave dielectric ceramic are: ZnO, MgO and H 3 BO 3 , the microwave dielectric ceramic also includes SiO with a mass fraction of 15%, 2% and 5% respectively 2 、TiO 2 and Al 2 o 3 .

[0046] Correspondingly, the present invention also provides a low dielectric constant, low loss microwave dielectric ceramic preparation method, comprising the following steps:

[0047] S1, the raw materials ZnO, MgO and H 3 BO 3 According to the chemical formula xZnO-yMgO-zB 2 o 3 The composition batching, wherein x=2, y=1, z=2, and put the raw material mixture according to the chemical formula batching into the ball mill, add deionized water and zirconia balls with a diameter of 2mm and ball mill at a spe...

Embodiment 3

[0053] The invention provides a microwave dielectric ceramic with low dielectric constant and low loss. The main crystal phase structure formula of the microwave dielectric ceramic is: xZnO-yMgO-zB 2 o 3 , where x=3, y=0.5, z=1, and the raw materials of the main crystal phase of the microwave dielectric ceramic are: ZnO, MgO and H 3 BO 3 , the microwave dielectric ceramic also includes SiO with a mass fraction of 5%, 4% and 15% respectively 2 、TiO 2 and Al 2 o 3 .

[0054] Correspondingly, the present invention also provides a low dielectric constant, low loss microwave dielectric ceramic preparation method, comprising the following steps:

[0055] S1, the raw materials ZnO, MgO and H 3 BO 3 According to the chemical formula xZnO-yMgO-zB 2 o 3 Composition batching, wherein x=3, y=0.5, z=1, and put the raw material mixture according to the chemical formula batching into a ball mill, add deionized water and zirconia balls with a diameter of 2mm and ball mill at a speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com