Degradable photocurable resin prepolymer and preparation method, photocurable resin and preparation method

A technology of photocurable resin and prepolymer, which is applied in the field of photocurable resin and its respective preparation and degradable photocurable resin prepolymer, which can solve the problems of environmental pollution and refractory degradation, and achieve the reduction of side reactions, fast curing speed, The effect of reducing bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

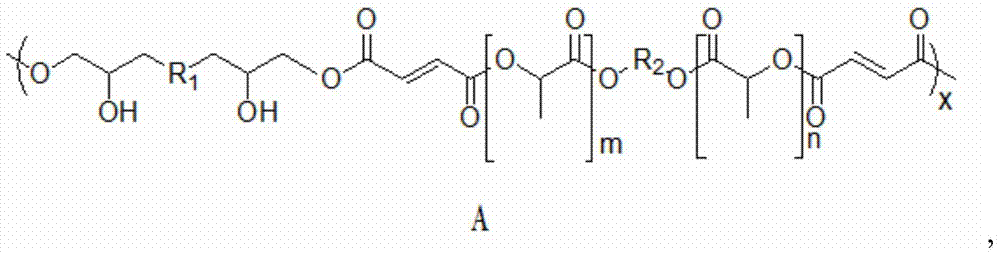

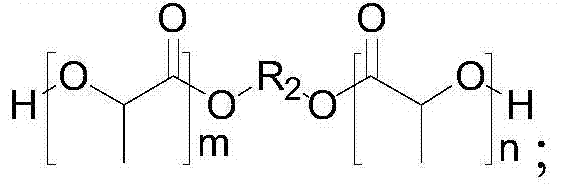

[0032] The R of the polylactide diol 2 The group is The epoxy reactive diluent used is polypropylene glycol diglycidyl ether with an epoxy value of 0.2886mol / 100g; the epoxy value of the E51 bisphenol A epoxy resin used is 0.5078mol / 100g.

[0033] Take 24.5g of maleic anhydride and 65.5g of polylactide diol into a 250ml three-necked flask, set an oil bath to heat at 60°C, heat at 70°C for 1 hour after the solid is completely dissolved, and then heat at 75°C for 1 hour to obtain light yellow Clear transparent liquid; take by weighing 24.6g E51 bisphenol A type epoxy resin, 43.3g polypropylene glycol diglycidyl ether, 0.7880g tetraethylammonium bromide, 0.1586g p-hydroxyanisole and join in the above-mentioned product, heat up React at 80° C. for 2 hours, then raise the temperature to 90° C. and react for 6 hours to obtain light yellow degradable photocurable resin prepolymer 1 .

[0034] Weigh 45.0g of tripropylene glycol diacrylate, 4.0007g of phenylbis(2,4,6-trimethylbenzoy...

Embodiment 2

[0037]The R group in the polylactide diol is The hydroxyl value is 214.06mg KOH·g -1 The epoxy reactive diluent used is polypropylene glycol diglycidyl ether with an epoxy value of 0.2886mol / 100g; the epoxy value of the E51 bisphenol A type epoxy resin used is 0.5078mol / 100g.

[0038] Take 49.0g maleic anhydride and 131.0g polylactide diol into a 500ml three-necked flask, set an oil bath to heat at 60°C, heat at 70°C for 1 hour after the solid is completely dissolved, and then heat at 75°C for 1 hour to obtain light yellow Clear transparent liquid; take by weighing 49.2g E51 bisphenol A type epoxy resin, 86.6g polypropylene glycol diglycidyl ether, 1.5799g tetramethylammonium bromide, 0.3164g p-methoxyphenol and join in the above-mentioned product, heat up React at 80° C. for 2 hours, then raise the temperature to 90° C. and react for 6 hours to obtain light yellow viscous degradable photocurable resin prepolymer 2 .

[0039] Weigh 90.0g of tripropylene glycol diacrylate, 8...

Embodiment 3

[0042] The R group in the polylactide diol is The hydroxyl value is 214.06mgKOH·g -1 The epoxy reactive diluent used is ethylene glycol glycidyl ether, and the epoxy value is 0.7401mol / 100g; the epoxy value of the E51 bisphenol A type epoxy resin used is 0.5078mol / 100g.

[0043] Take 49.0g maleic anhydride and 131.0g polylactide diol into a 500ml three-necked flask, set an oil bath to heat at 60°C, heat at 70°C for 1 hour after the solid is completely dissolved, and then heat at 75°C for 1 hour to obtain light yellow Clear transparent liquid; Take by weighing 49.2g E51 bisphenol A type epoxy resin, 33.8g ethylene glycol diglycidyl ether, 1.3155g tetraethylammonium bromide, 0.2621g p-hydroxyanisole and join in the above-mentioned product, Raise the temperature to 80° C. for 2 hours, and then raise the temperature to 90° C. for 6 hours to obtain light yellow viscous degradable photocurable resin prepolymer 3 .

[0044] Weigh 90.0g of tripropylene glycol diacrylate, 8.0011g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com