Method for treating pickled soft base through industrial residues

A technology of industrial waste and soft foundation, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of not considering the characteristics of saline soft soil foundation, the treatment effect is not very ideal, and restricting the sustainable development of society, etc., to achieve The effect of reducing the dissolution and moisture absorption deformation, reducing the occupied space, and greatly increasing the water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following further illustrates through specific examples.

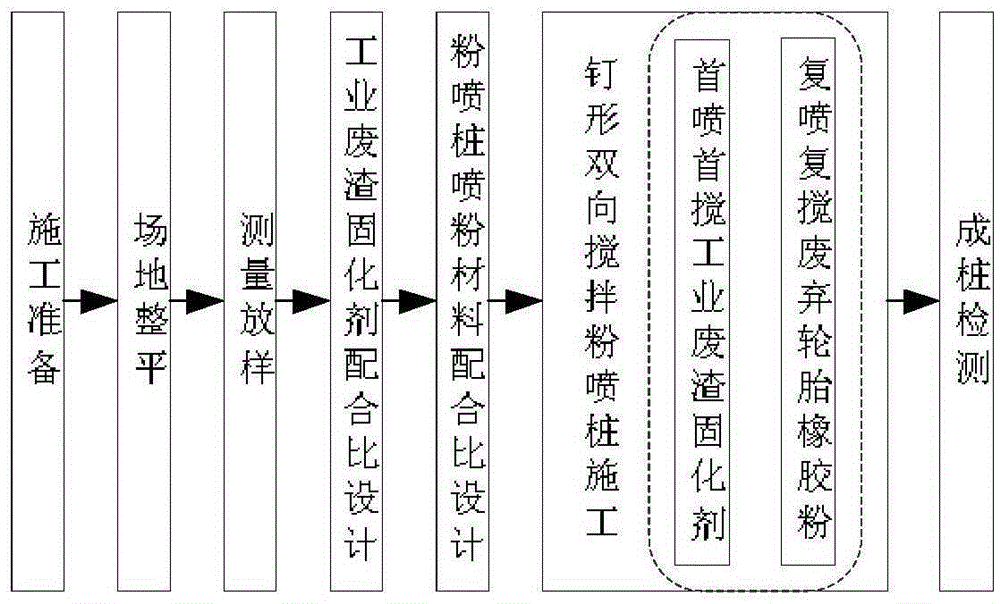

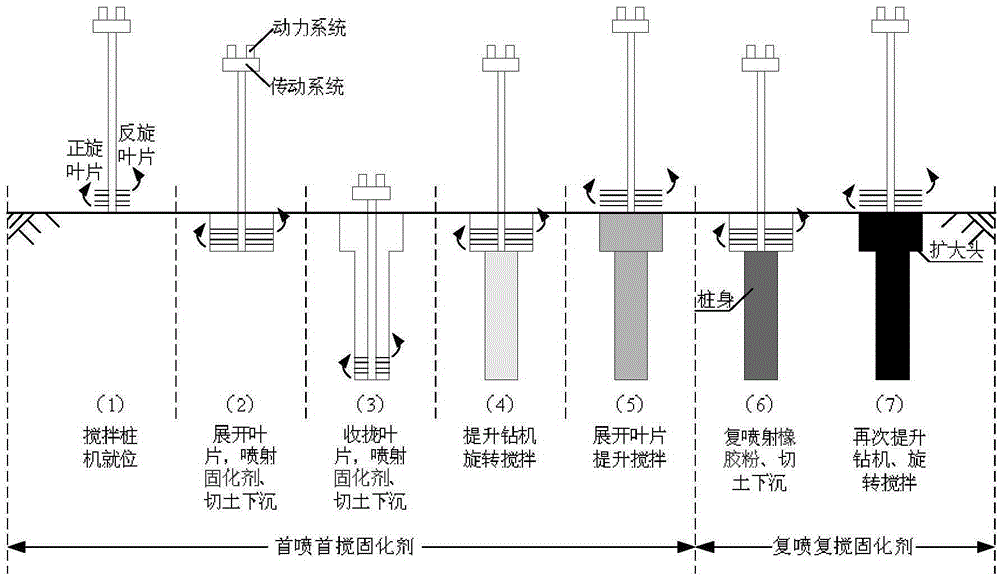

[0022] 1. Construction process

[0023] "Industrial waste slag jet mixing pile treatment of coastal saline soft foundation" construction process see figure 1 .

[0024] 1.1 Construction preparation

[0025] Avoid rainy season or bad weather when starting work. Make preparations for construction before starting construction and strengthen construction organization and management.

[0026] Allocate construction personnel, materials and mechanical equipment, and clarify construction methods, processes and procedures. At the same time, do a good job in safety and quality management, and do a good job in water and electricity.

[0027] 1.2 Leveling the site

[0028] Remove surface floating soil, thin layer of "skin" and various debris to ensure a clean and flat surface, which is convenient for construction machinery to enter the site. In case of concealed grooves, holes or local loose soil, they should be removed in time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com