Cu@Cu-Au nano-particle with core-shell structure and preparation method and application thereof

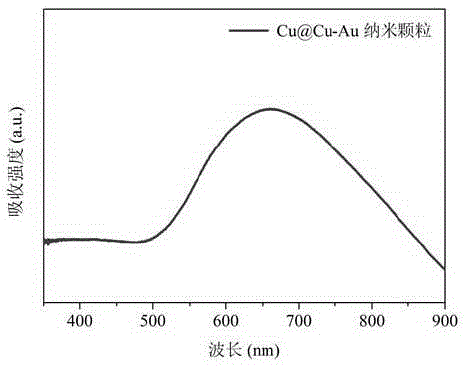

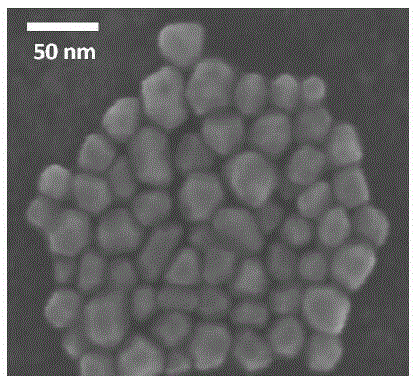

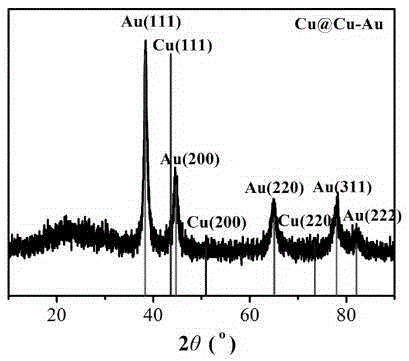

A nanoparticle, core-shell structure technology, applied in the direction of nanotechnology, final product manufacturing, organic semiconductor devices, etc., can solve the problems of poor stability, easy to be oxidized, loss of optical and electrical properties, etc., to achieve stable properties and wide absorption spectrum , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of CuCu-Au nanoparticles.

[0040] (1) Form a single copper inner core:

[0041] Weigh 8mg (0.1mmol) of CuO and place it in a round bottom flask, add 1.6mL of oleic acid and 1.6mL of 1-octadecene mixture, stir well to obtain a uniform black suspension; replace the atmosphere of the system with In Ar atmosphere, heated to 230°C under stirring condition and kept for 30min to obtain a brown-yellow solution; slowly added 1.4mL (4.3mmol) oleylamine dropwise to the above system, 2+ Reduction to elemental Cu to obtain a suspension of elemental Cu nanoparticles;

[0042] (2) Construction of gold-copper core shell:

[0043] Under an argon atmosphere, add 120 μL HAuCl dropwise to the above system 4 solution in toluene (wherein HAuCl 4 The mass is 0.8mg), at this time the temperature of the system drops slightly, when the temperature of the system drops to 140°C, slowly add 4mLAu (PPh 3 )Cl o-dichlorobenzene solution (wherein Au(PPh 3 )Cl mass is 35mg)...

Embodiment 2

[0050] Example 2: Preparation of CuCu-Au nanoparticles.

[0051] (1) Form a single copper inner core:

[0052] Weigh 8mg (0.1mmol) of CuO and place it in a round bottom flask, add 1.6mL of oleic acid and 1.6mL of 1-octadecene mixture, stir well to obtain a uniform black suspension; replace the atmosphere of the system with In Ar atmosphere, heated to 230°C under stirring condition and kept for 30min to obtain a brown-yellow solution; slowly added 1.4mL (4.3mmol) oleylamine dropwise to the above system, 2+ Reduction to elemental Cu to obtain a suspension of elemental Cu nanoparticles;

[0053] (2) Construction of gold-copper core shell:

[0054] Under an argon atmosphere, add 120 μL HAuCl dropwise to the above system 4 solution in toluene (wherein HAuCl 4 The mass is 0.8mg), at this time the temperature of the system drops slightly, when the temperature of the system drops to 140°C, slowly add 4mLAu (PPh 3 )Cl o-dichlorobenzene solution (wherein Au(PPh 3 )Cl mass is 30mg)...

Embodiment 3

[0058] Example 3: Preparation of CuCu-Au nanoparticles.

[0059] (1) Form a single copper inner core:

[0060] Weigh 8mg (0.1mmol) of CuO and place it in a round bottom flask, add 1.6mL of oleic acid and 1.6mL of 1-octadecene mixture, stir well to obtain a uniform black suspension; replace the atmosphere of the system with In Ar atmosphere, heated to 230°C under stirring condition and kept for 30min to obtain a brown-yellow solution; slowly added 1.4mL (4.3mmol) oleylamine dropwise to the above system, 2+ Reduction to elemental Cu to obtain a suspension of elemental Cu nanoparticles;

[0061] (2) Construction of gold-copper core shell:

[0062] Under an argon atmosphere, add 120 μL HAuCl dropwise to the above system 4 solution in toluene (wherein HAuCl 4 The mass is 0.8mg), at this time the temperature of the system drops slightly, when the temperature of the system drops to 140°C, slowly add 4mLAu (PPh 3 )Cl o-dichlorobenzene solution (wherein Au(PPh 3 )Cl mass is 40mg)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com