Lead-carbon battery positive electrode lead plaster added with electroconductive glass fiber

A technology of conductive glass fiber and positive lead paste, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of short cycle life and fast softening of active materials, and achieve long battery life, improve bonding strength, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of tin antimony oxide layer: Add citric acid to ethylene glycol under stirring and react at 55-65°C for about 30 minutes to obtain an alcohol solution of ethylene glycol citrate, raise the temperature to 85-95°C, and then Add SnCl4·5H2O and SbCl3 metal salt, fully stir and dissolve for about 30 minutes, and obtain tin-antimony polymerization precursor solution (in light yellow transparent viscous liquid). The mol ratio of the citric acid, ethylene glycol molar total and metal salt is 3:14. The molar ratio of citric acid and ethylene glycol can be 1:1-1.5 (the molar ratio selected in this embodiment is 1:1), and the molar ratio of SnCl4·5H2O to SbCl3 is 9:1.

[0020] (2) Preparation of conductive glass fiber: According to the ratio of 150ml precursor / 100g fiber, the glass fiber with a length of 2mm~5mm and a single fiber fineness of 1.5D~3D is evenly mixed with the tin-antimony polymerization precursor solution (so that the fiber surface Just coat the pr...

Embodiment 2

[0028] (3) Preparation of positive lead paste: In terms of the percentage of lead powder weight, the following substances account for the weight of lead powder: 0.2% of stannous sulfate, 0.15% of antimony trioxide, 0.8% of conductive glass fiber, and a density of 1.40g / mL 8.5% sulfuric acid, 11.5% deionized water. All the other implementations are as in Example 1. The results of the test battery performance are shown in Table 2.

[0029] For the common battery used for comparison in Table 2, except that the conductive glass fiber is replaced by 0.8% graphite in the positive plate lead paste, all the other components and proportioning are as in Example 2, and the negative plate is the used plate of a conventional lead-acid battery. For the lead-carbon battery used for comparison in Table 2, the positive plate is the same as the above-mentioned common battery, and the negative plate is a lead-carbon plate (same as Example 1).

[0030] Table 2

[0031]

[0032] It can be se...

Embodiment 3

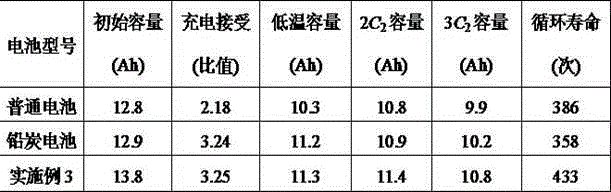

[0034] (3) Preparation of positive lead paste: Calculated as a percentage of the weight of lead powder, the following substances account for the weight of lead powder: 0.2% of stannous sulfate, 0.15% of antimony trioxide, 0.6% of conductive glass fiber, and 0.2% of graphite, with a density of 1.40g / mL sulfuric acid 8.5%, deionized water 11.5%. All the other implementations are as in Example 1. The test battery performance results are shown in Table 3.

[0035] For the common battery used for comparison in Table 3, except that the conductive glass fiber is replaced by 0.6% graphite in the positive plate lead paste, all the other components and proportioning are as in Example 3, and the negative plate is the used plate of a conventional lead-acid battery. For the lead-carbon battery used for comparison in Table 2, the positive plate is the same as the above-mentioned common battery, and the negative plate is a lead-carbon plate (same as Example 1).

[0036] table 3

[0037] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Single fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com