Composite protein beverage and preparation method thereof

A compound protein and beverage technology, which is applied in the field of compound protein beverage and its preparation, can solve the problems that the compound protein drink needs to be improved, and achieve the effects of good taste, stability and taste, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

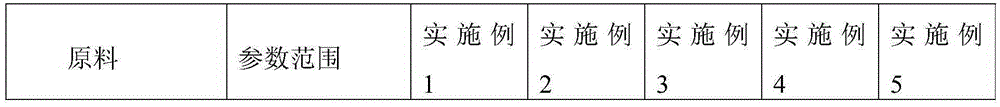

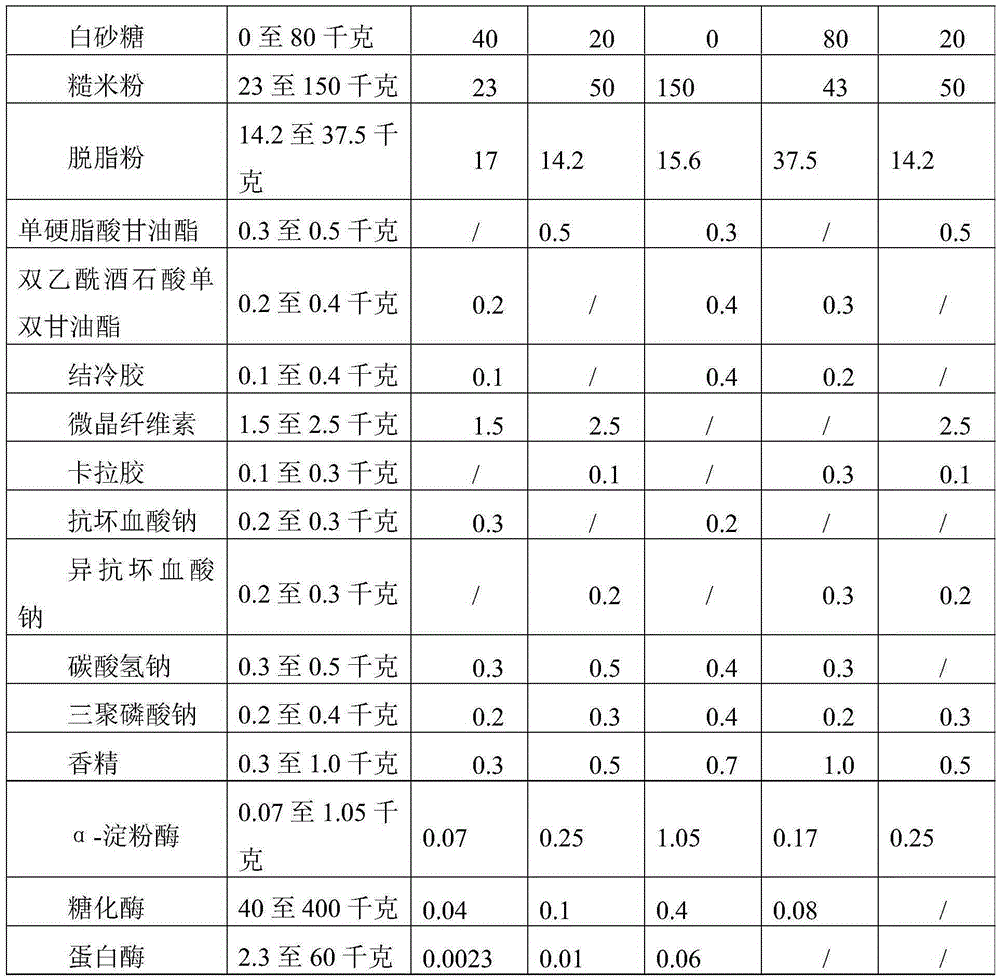

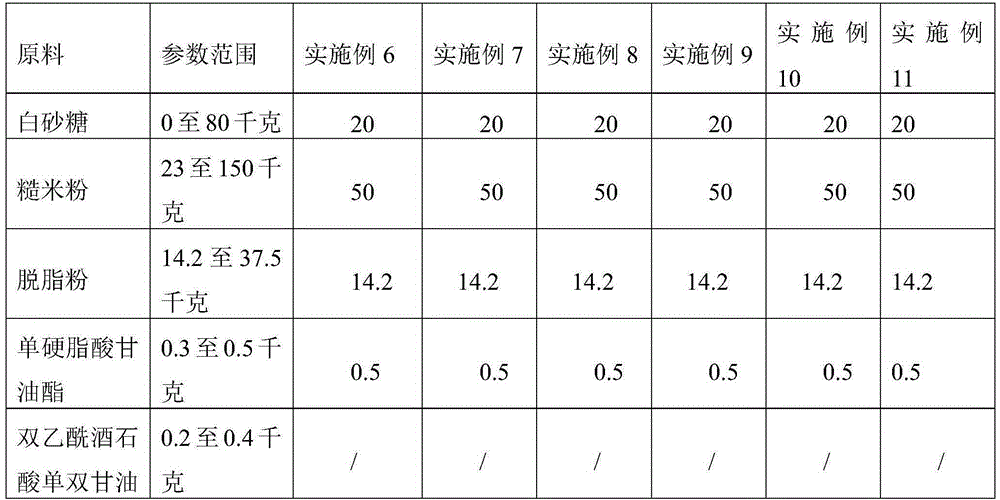

Embodiment 1

[0041] 1. Raw materials

[0042] Brown rice flour: 23 kg, roasted brown rice flour;

[0043] Skim milk powder: 17 kg;

[0044] Stabilizer: 2.6 kg, including 0.1 kg of gellan gum, 1.5 kg of microcrystalline cellulose, 0.2 kg of diacetyl tartrate mono-diglyceride, 0.3 kg of sodium ascorbate, 0.3 kg of sodium bicarbonate, and 0.2 kg of sodium tripolyphosphate;

[0045] Enzymes: 112.3 grams, including 70 grams of α-amylase, 40 grams of glucoamylase, and 2.3 grams of protease;

[0046] White sugar: 40 kg;

[0047] Flavor: 0.3 kg;

[0048] Water: 917 kg.

[0049] 2. Preparation method

[0050] a. Stir and disperse brown rice flour in cold water 4 times its weight, add α-amylase, glucoamylase and protease, heat while stirring, raise the temperature to 65°C, keep the temperature for 40 minutes, and then continue heating to 90°C, Keep the temperature for 20 minutes, lower the temperature to 10°C, and obtain the enzymatically hydrolyzed brown rice solution for use;

[0051] b. Ad...

Embodiment 2

[0059] 1. Raw materials

[0060] Brown rice flour: 50 kg, roasted brown rice flour;

[0061] Skim milk powder: 14.2 kg;

[0062] Stabilizer: 3.9 kg, including 2.5 kg of microcrystalline cellulose, 0.1 g of carrageenan, 0.3 kg of glyceryl monostearate, 0.2 kg of sodium erythorbate, 0.5 kg of sodium bicarbonate, and 0.3 kg of sodium tripolyphosphate;

[0063] Enzymes: 360 grams, including 250 grams of α-amylase, 100 grams of glucoamylase, and 10 grams of protease;

[0064] White sugar: 20 kg;

[0065] Flavor: 0.5 kg

[0066] Water: 911 kg.

[0067] 2. Preparation method

[0068] a. Stir brown rice flour in cold water 4 times its weight, add α-amylase, glucoamylase and protease, heat while stirring, raise the temperature to 70°C, keep this temperature for 20 minutes, then continue to heat to 95°C, keep The temperature is 15 minutes, and the temperature is lowered to 15°C to obtain the enzymatically hydrolyzed rice solution, which is ready for use;

[0069] b. Add skim milk p...

Embodiment 3

[0077] 1. Raw materials

[0078] Brown rice flour: 150 kg, roasted brown rice flour;

[0079] Skim milk powder: 15.6 kg;

[0080] Stabilizer: 1.9 kg, including 0.4 kg of gellan gum, 0.5 kg of glyceryl monostearate, 0.2 kg of sodium ascorbate, 0.4 kg of sodium bicarbonate, and 0.4 kg of sodium tripolyphosphate;

[0081] Enzymes: 1.53 grams, including 1.05 kilograms of α-amylase, 0.4 grams of glucoamylase, and 0.08 grams of protease;

[0082] Flavor: 0.7 kg;

[0083] Water: 830.27 kg.

[0084] 2. Preparation method

[0085] a. Stir and disperse brown rice flour in cold water 4 times its weight, add α-amylase, glucoamylase and protease, heat while stirring, raise the temperature to 75°C, keep the temperature for 30 minutes, and then continue heating to 100°C , keep the temperature for 5 minutes, lower the temperature to 25°C, and obtain the enzymatically hydrolyzed rice solution for use;

[0086] b. Add skim milk powder to water at 45-65°C, stir for 15 minutes, then let sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com