A kind of high activity Fischer-Tropsch synthesis catalyst and its preparation method and application

A Fischer-Tropsch synthesis and catalyst technology, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve the problem of low catalyst activity, achieve CO2 selectivity reduction, suppress WGS reaction, and increase the strength Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

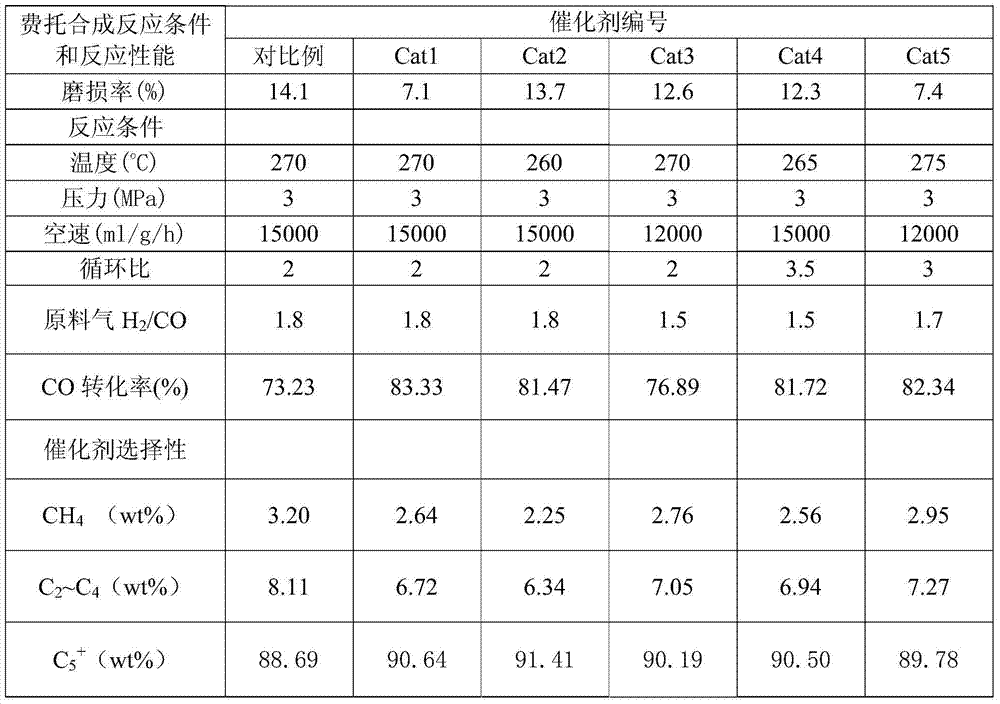

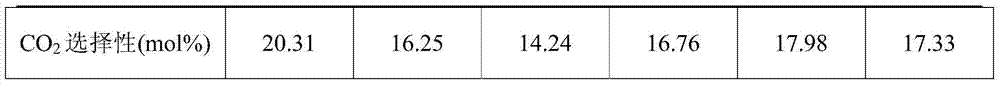

Examples

Embodiment 1

[0064] Fe(NO 3 ) 3 9H 2 O reagent 30kg, adding deionized water to prepare a 30% nitrate solution. Take Cu(NO 3 ) 2 ·3H 2 O reagent 0.788kg, La(NO 3 ) 3 ·6H 2 O reagent 1.293kg, add deionized water to prepare a mixed solution of the precursor of 20% auxiliary agent A, get the carrier auxiliary agent after mixing 6.963kg of silica sol with a concentration of 10% and 6.635kg of aluminum sol with a concentration of 10% Precursor solution of B. Add the mixed solution of the precursor of auxiliary agent A and the precursor solution of auxiliary agent B to the nitrate solution in sequence, and mix well. Adjust the temperature of the mixed solution to 80°C, prepare an ammonia solution with a concentration of 20%, and adjust the temperature of the ammonia solution to 40°C. Turn on the stirring and ultrasonic device of the synthesis reactor, and control the ultrasonic frequency to 50kHz. The mixed solution and alkali solution are fed into the synthesis reactor concurrently. ...

Embodiment 2

[0066] Fe(NO 3 ) 3 9H 2 O reagent 30kg, adding deionized water to prepare a nitrate solution with a concentration of 20%. Take Ce(NO 3 ) 3 ·6H 2 O reagent 0.771kg, Mg(NO 3 ) 2 ·6H 2 O reagent 1.750kg, adding deionized water to prepare a mixed solution of the precursor of the structural aid A with a concentration of 20%, taking a concentration of 20% silica sol 1.441kg and a concentration of 15% zirconium sol 8.294kg mixed to obtain a carrier Precursor solution of Adjuvant B. Add the mixed solution of the precursor of auxiliary agent A and the precursor solution of auxiliary agent B to the nitrate solution in sequence, and mix well. Adjust the temperature of the mixed solution to 40°C, prepare an ammonia solution with a concentration of 10%, and adjust the temperature of the ammonia solution to 30°C. Turn on the stirring and ultrasonic device of the synthesis reactor, and control the ultrasonic frequency to 20kHz. The mixed acid solution and alkali solution are fed i...

Embodiment 3

[0068] Fe(NO 3 ) 3 9H 2 O reagent 30kg, adding deionized water to prepare a 35% nitrate solution. Take the concentration of 50% Mn(NO 3 ) 2 Solution 1.621kg, Mg(NO 3 ) 2 ·6H 2O reagent 3.062kg, add deionized water to prepare a mixed solution of the precursor of 10% auxiliary agent A, get a concentration of 30% silica sol 3.318kg and a concentration of 20% zirconium sol 5.320kg after mixing to obtain a carrier auxiliary agent Precursor solution of B. Add the mixed solution of the precursor of auxiliary agent A and the precursor solution of auxiliary agent B to the nitrate solution in sequence, and mix well. Adjust the temperature of the mixed solution to 50°C, prepare an ammonia solution with a concentration of 20%, and adjust the temperature of the ammonia solution to 40°C. Turn on the stirring and ultrasonic device of the synthesis reactor, and control the ultrasonic frequency to 30kHz. The mixed acid solution and alkali solution are fed into the synthesis reactor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com