Heterogeneous electric Fenton system and preparation and application thereof

A system and electrode technology, applied in natural water treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problem of lack of improving the pH value range of wastewater treated by electric Fenton system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] Preparation of Electro-Fenton System

[0092] Electro-Fenton system of the present invention mainly comprises the following steps:

[0093] (1) preparing the composite cathode electrode, wherein the composite cathode electrode contains graphene, metal oxide and polytetrafluoroethylene;

[0094] (2) Assembling the composite cathode electrode prepared in step (1) with an inert anode and an electrolyte solution into an electro-Fenton system as described in the first aspect of the present invention.

[0095] In another preferred example, the method further includes step (3): adding pollutants to be treated or waste liquid containing the pollutants to the electric Fenton system obtained in the previous step, and electrifying at a certain voltage for a period of time. time to degrade the pollutants.

[0096] In another preferred example, in the step (1), it includes: mixing the following electrode raw materials to obtain the first mixture: graphene, metal oxide, polytetrafl...

Embodiment 1

[0120] Preparation and Application of Electro-Fenton System No.1

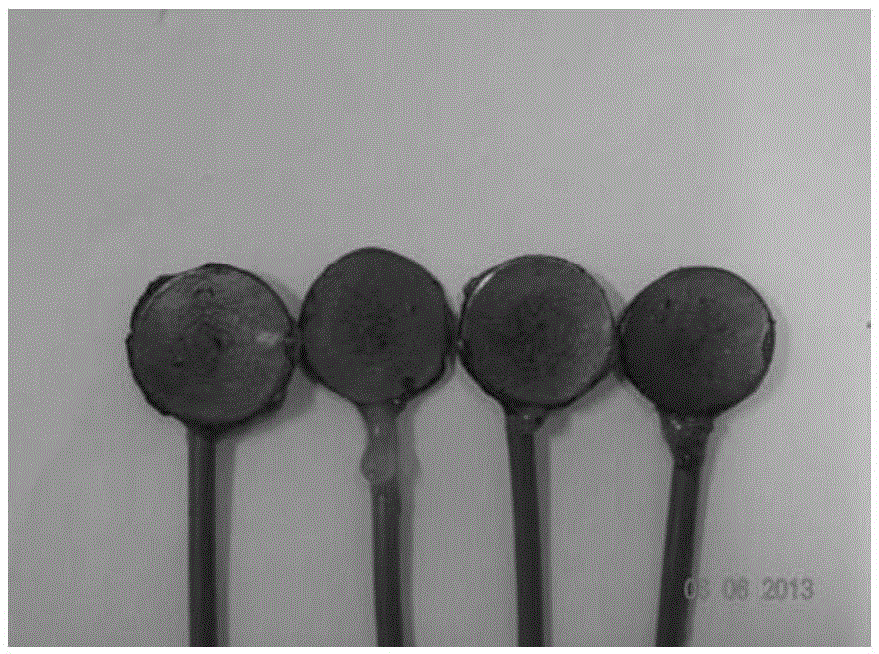

[0121] Weigh 10g graphene, 2gCu 2 O (particle size 5-10 μm), add 2 drops of "OP" emulsifier (purchased from Hai'an Petrochemical Factory in Jiangsu Province), 2 mL of absolute ethanol and 0.8 g of polytetrafluoroethylene, and ultrasonically disperse evenly until the mixture forms a coagulated Paste, roll the paste into a film of about 2.5mm, attach the film up and down to the metal nickel mesh, press it under a pressure of 30MPa to obtain a graphene / cuprous oxide electrode, soak it in acetone solution for 2h to remove the residual residue on the electrode surface Alcohol and "OP" emulsifier. Keep warm at 80°C for 2 hours in an infrared box to make a composite cathode electrode, and its final size: bottom area × height = 1.0cm 2 ×5mm. Its appearance photo see figure 1 . figure 1 is a photo of the pressed composite cathode electrode, which is circular and sealed with epoxy resin on the back.

[0122] The pr...

Embodiment 2

[0127] Preparation and Stability Test of Electro-Fenton System No.2

[0128] Weigh 12g graphene, 3gCu 2 O, add 1 drop of "OP" emulsifier, 1.5mL of absolute ethanol and 0.9g of polytetrafluoroethylene, ultrasonically disperse evenly until the mixture forms a cohesive paste, roll the paste into a film of about 3mm, adhere On the nickel mesh, the graphene / cuprous oxide electrode was pressed under 30MPa pressure, soaked in acetone solution for 2h to remove the residual ethanol and "OP" emulsifier on the electrode surface. Keep warm at 80°C for 2 hours in an infrared box to make a composite cathode electrode, and its final size: bottom area × height = 1.0cm 2 ×6mm.

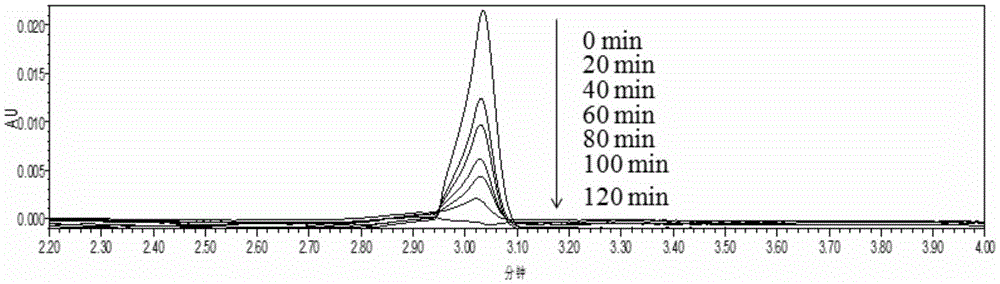

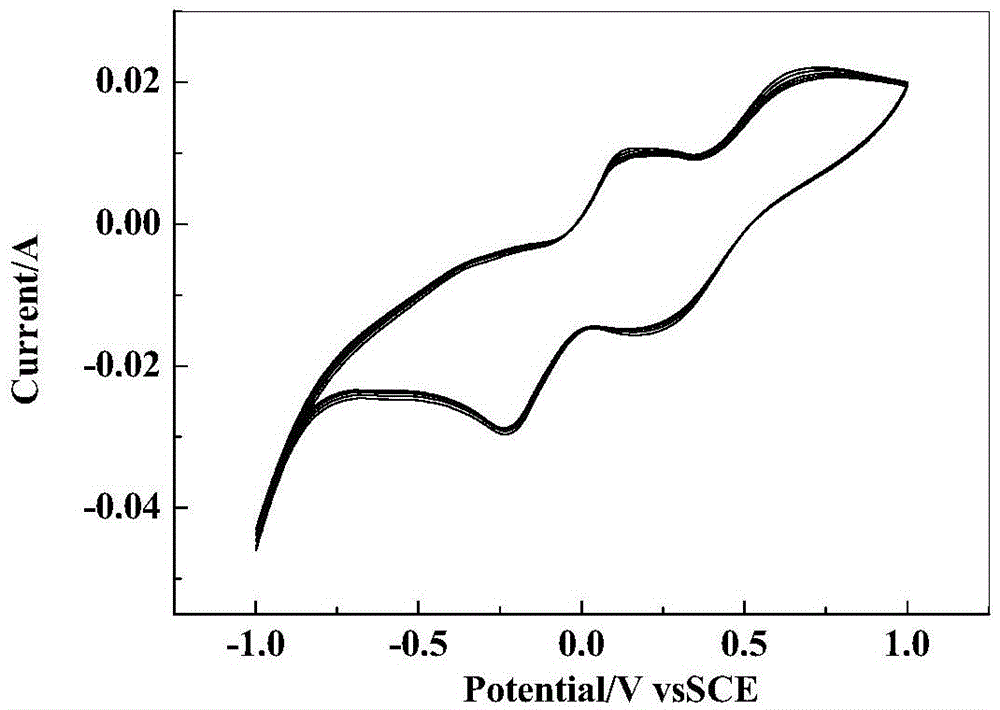

[0129] In order to detect the electrocatalytic stability of the composite cathode electrode, the prepared composite cathode electrode was used as the cathode, the platinum sheet was used as the anode, and the saturated calomel electrode was used as the reference electrode. 2 SO 4 To support the electrolyte, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com