Laboratory carbon tetrachloride separation treatment system and treatment process thereof

A carbon tetrachloride, separation and treatment technology, applied in oxidation water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of poor pollutant treatment effect, complex geological structure and equipment energy consumption Improve and other issues to achieve the effect of increasing contact time, high processing efficiency, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

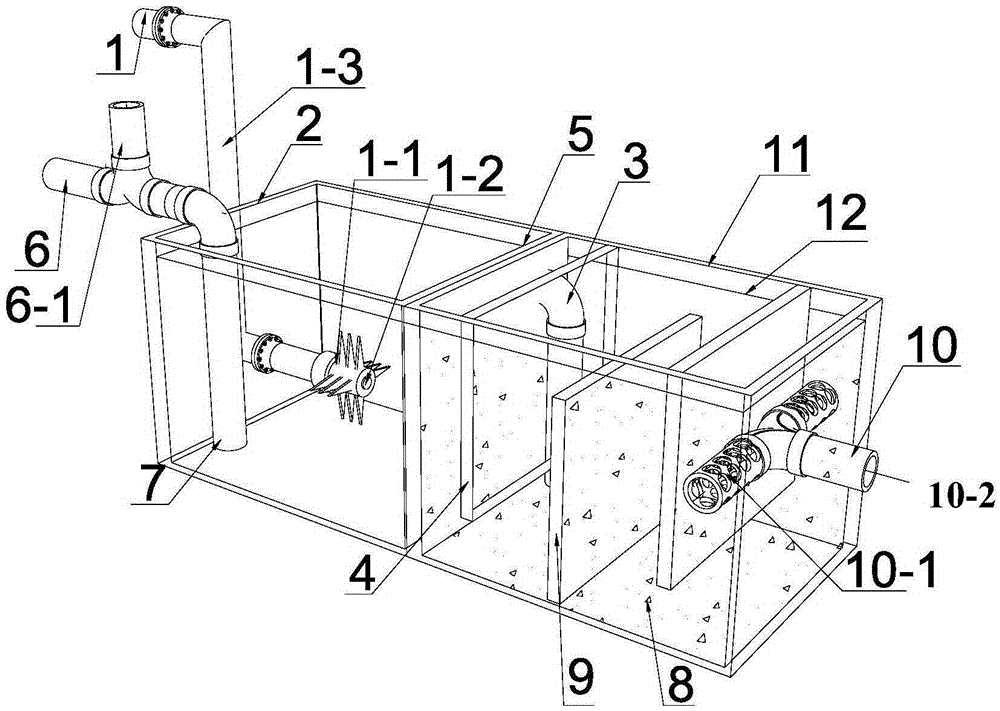

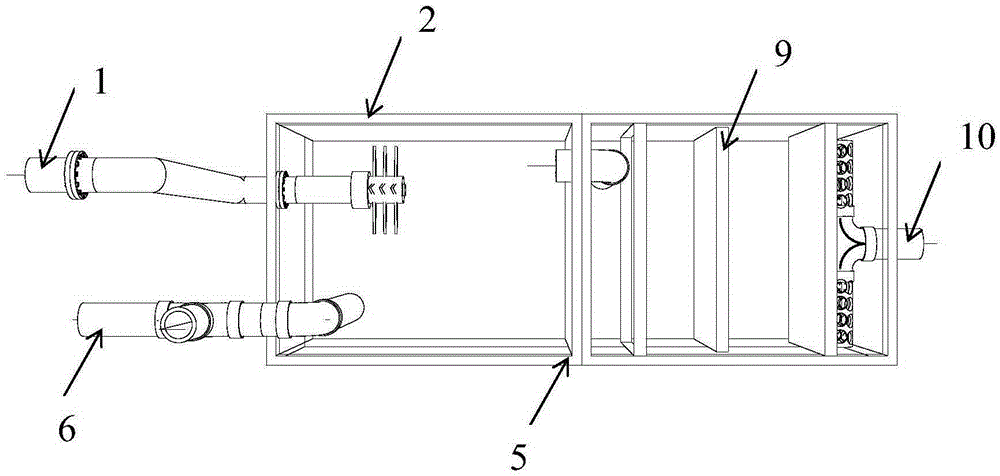

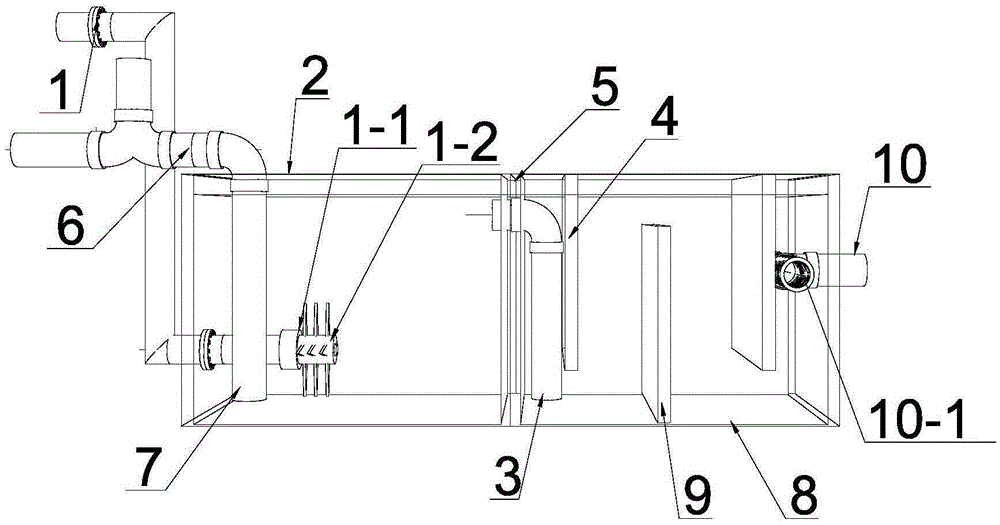

[0050] Such as figure 1 Shown, be the laboratory carbon tetrachloride separation treatment system structure schematic diagram of the present invention, can find out, comprise the activated carbon filter case 11 that contains S-shaped adsorption tank 4 and have the treatment area of nano-bubble generator 1, two Those placed in the aeration reaction box 2, separated by a partition 5, and communicated through the guide tube 3; wherein the S-shaped adsorption tank 4 is filled with activated carbon filler 8 and is provided with a suspended plate 9, one end of the S-shaped adsorption tank 4 A water outlet pipe 10 is provided; one end of the aeration reaction box 2 is provided with a residual liquid inlet pipe 6 .

[0051] Such as image 3 Shown is the front view of the laboratory carbon tetrachloride separation and treatment system of the present invention. It can be seen that the S-shaped adsorption tank 4 is formed by vertical dislocation of suspended plates 9, and the number o...

Embodiment 2

[0057] Utilize the above separation system to process the laboratory raffinate containing carbon tetrachloride. First, the carbon tetrachloride raffinate enters the aeration reaction box 2 through the raffinate inlet pipe 6, and the hydrogen peroxide reaction reagent passes through the hydrogen peroxide filling pipe 6- 1 enters the aeration reaction box 2 and reacts with the carbon tetrachloride residue; at the same time, the external air enters the nanobubble generator 1 through the air inlet pipe 1-3, and the high-speed rotor impeller 1-1 rotates at a speed of 3000-9000 rpm Rotating at a speed of 1 minute, the micro-bubbles generated by the microporous aeration head 1-2 are crushed into bubbles with a diameter of 10-600 nanometers, which are evenly diffused into the reaction box and mixed with tetrachloride in the aeration reaction box 2. Carbon fully reacts.

[0058] The treated solution enters the activated carbon filter box 11 through the guide pipe 3. Since the activated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com