Modified bismaleimide resin and preparation method thereof

A bismaleimide, modified technology, applied in the field of high-performance polymers, can solve the problems of unreported dielectric properties, poor stability, etc., achieve good dispersion and interfacial force, and small grain size , the effect of good moisture resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of amidated metal-organic frameworks

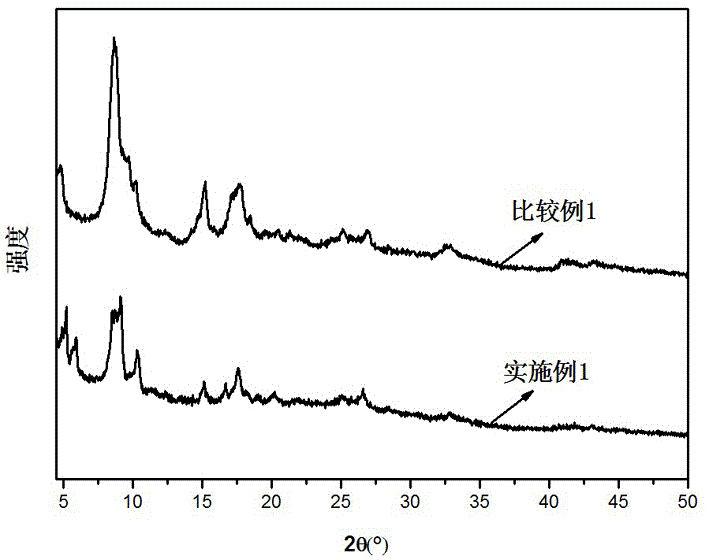

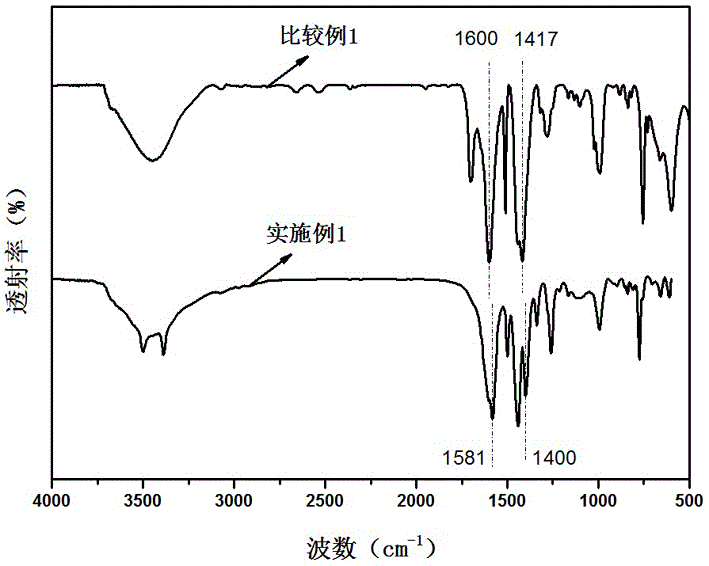

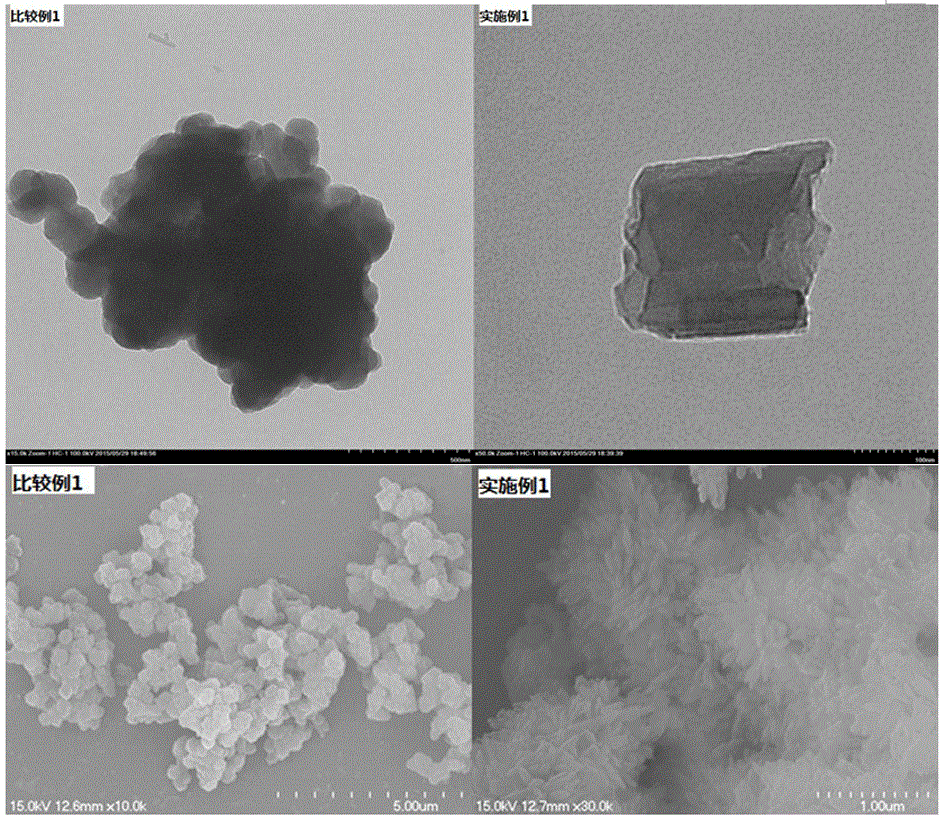

[0032] Under nitrogen protection, dissolve 0.272g of 2-aminoterephthalic acid in 62mL of N,N-dimethylformamide; add 0.724g of AlCl at a temperature of 110°C with stirring 3 ·6H 2 O, stirred until dissolved, and then kept at 110°C for 12 hours; after the reaction, naturally cooled to room temperature, filtered, washed with ethanol, and centrifuged, then activated with ethanol for 24 hours at 90°C. Vacuum drying yields amidated metal-organic frameworks. Its X-ray diffraction diagram, infrared spectrogram, SEM, TEM diagram and isothermal adsorption-desorption curve diagram are respectively shown in the attached figure 1 , 2 , 3 and 4.

[0033] 2. Preparation of modified bismaleimide resin cured product

[0034] Add 0.087g of amidated metal-organic framework prepared in step 1 of Example 1 to 37g of 2,2'-diallyl bisphenol A, and disperse with ultrasonic stirring for 30min to obtain mixture A; 50g of N,N'-4,4' - Diphe...

Embodiment 2

[0041] Preparation of Cured Product of Modified Bismaleimide Resin

[0042] Add 0.261g of the amidated metal-organic framework prepared in Example 1 to 37g of 2,2'-diallyl bisphenol A, and disperse with ultrasonic stirring for 30min to obtain mixture A; 50g of N,N'-4,4'-di Benzene bismaleimide was added to mixture A, stirred evenly, and the bismaleimide was melted at 140°C. After prepolymerization for 45 minutes, a prepolymer was obtained, and the prepolymer was vacuum degassed at 140°C for 10 minutes. , and then pour the prepolymer into the preheated mold, and then vacuum defoam at 140°C for 20min; A modified bismaleimide resin is obtained after curing and post-treatment respectively at 240° C. / 4 hours. Its dielectric constant-frequency curve, dielectric loss-frequency curve, impact strength, storage modulus-temperature change curve and bending strength refer to the attached Figure 5 , 6 , 7, 8 and 9.

Embodiment 3

[0050] 1. Preparation of amidated metal-organic frameworks

[0051] Under nitrogen protection conditions, dissolve 0.217g of 2-aminoterephthalic acid in 31mL of N,N-dimethylformamide; at a temperature of 110°C and stirring conditions, add 0.724g of AlCl 3 ·6H 2 O, stirred for 4 hours, and kept at a temperature of 110°C for 12 hours; after the reaction, naturally cooled to room temperature, filtered, washed with ethanol, and centrifuged; then activated with ethanol for 22 hours at 90°C, and freeze-dried to obtain Aminated metal-organic frameworks.

[0052] 2. Preparation of modified bismaleimide resin cured product

[0053] Add 0.080 g of the amidated metal-organic framework prepared in step 1 of Example 3 to 30 g of 2,2'-diallyl bisphenol A, and disperse with ultrasonic stirring for 30 minutes to obtain mixture A; 50 g of N,N'-4, Add 4'-diphenylmethane bismaleimide to mixture A, stir evenly, and melt the bismaleimide at 130°C. After prepolymerization for 45 minutes, a prepo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com