Preparation method of water-soluble polyaniline

A polyaniline, water-soluble technology, applied in the field of preparation of water-soluble polyaniline, can solve the problem of low degree of copolymer grafting, large steric hindrance of methoxy polyethylene glycol o-aminophenyl ether, and difficult grafting rate. control and other issues, to achieve the effects of easy process control, high atomic utilization, and easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

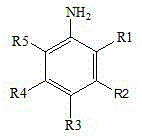

Image

Examples

Embodiment 1

[0027] Dissolve 14.88g of aniline, 5.0g of o-aminothiophenol, and 6.53g of dodecylbenzenesulfonic acid into 200mL of water, stir evenly, and keep the temperature at 0°C for 30min to prepare an aniline aqueous solution. Dissolve 22.8g of ammonium persulfate in 140mL of 0.5mol / L hydrochloric acid, stir well and keep the temperature at 0°C for 30min. The above two solutions were mixed and reacted at 0°C for 3 hours to obtain low molecular weight water-soluble polyaniline.

[0028] Adjust the pH of the above reaction solution to 8~9 with ammonia water, add 4.0g triethylamine and 15.0g polyethylene glycol methacrylate (molecular weight: 300), heat the reaction solution to 70°C, and react for 3 hours. After the reaction, cool down to 0°C, add 8mL of concentrated hydrochloric acid and 22.8g of ammonium persulfate, and react at 0°C for 12 hours. After the reaction, pour the reaction solution into 1000mL of acetone for precipitation. Vacuum dried for 24 hours to obtain water-soluble p...

Embodiment 2

[0030] Dissolve 14.88g of aniline and 7.5g of o-aminothiophenol into 200mL of water, stir evenly, and keep the temperature at 0°C for 30min to prepare an aqueous solution of aniline. Dissolve 25.8g of ammonium persulfate in 100mL of 1.0mol / L hydrochloric acid, stir well and keep the temperature at 0°C for 30min. The above two solutions were mixed and reacted at 0°C for 3 hours to obtain low molecular weight water-soluble polyaniline.

[0031] Adjust the pH of the above reaction solution to 8~9 with ammonia water, add 6.0g of triethylamine and 20.0g of polyethylene glycol methacrylate (molecular weight: 300), heat the reaction solution to 70°C, and react for 3 hours. After the reaction, cool down to 0°C, add 8mL of concentrated hydrochloric acid and 25.8g of ammonium persulfate, and react at 0°C for 12 hours. After the reaction, pour the reaction solution into 1000mL of acetone for precipitation. Vacuum dried for 24 hours to obtain water-soluble polyaniline with a yield of 83%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com