Waste tyre powder modified asphalt and preparation method therefor

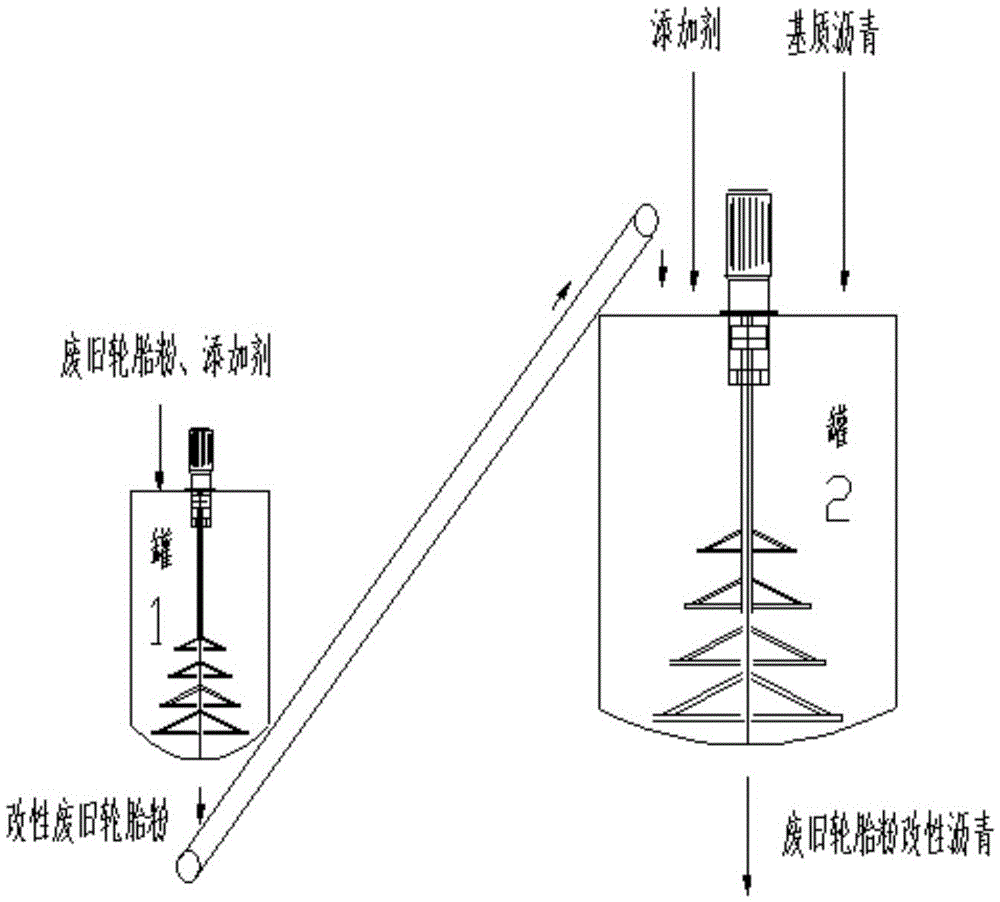

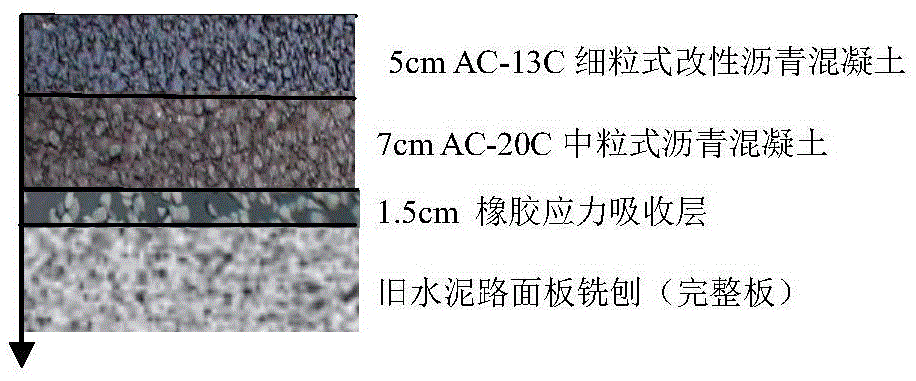

A technology of waste tire powder and modified asphalt, which is applied in the direction of coagulation pavement, building components, building insulation materials, etc. laid on site, can solve the production limit of waste rubber modified asphalt, can not meet the needs of road construction development, Harm the physical and mental health of workers and other problems, and achieve the effects of low production temperature, increased dispersion uniformity of rubber powder, interface bonding force, and reduced penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

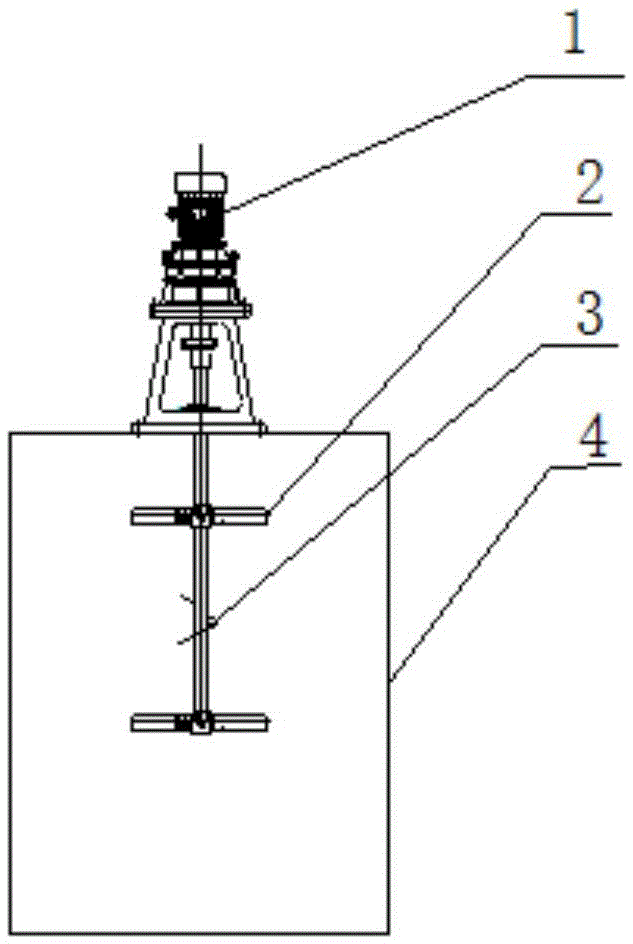

Method used

Image

Examples

Embodiment 1

[0039] Taking the production of the waste tire powder modified asphalt product in the present invention as an example, the particle size of the waste tire powder described in the formula is 40 mesh, and the waste tire powder is selected from large truck wheel waste tire powder (DK). The weight of each component is as follows:

[0040] Modified waste tire powder (DK) 18kg

[0041] Zhonghai AH-70# asphalt 81kg

[0042] WJ-1 stabilizer 0.1kg;

[0043] Wherein, the above-mentioned waste tire powder (DK) is composed of the following raw materials in parts by weight: waste tire powder (DK) 17.73kg, diethylenetriamine 0.18kg, cuprous chloride 0.09kg;

[0044] The 0.1kg WJ-1 stabilizer mentioned above is composed of the following raw materials in parts by weight: sulfur: 0.075kg, rosin 0.019kg, talcum powder 0.005kg, dioctyl phthalate 0.001kg.

[0045] The above-mentioned waste tire powder modified asphalt is prepared by the following method:

[0046] (1) Take 17.73kg of waste tir...

Embodiment 2

[0050] Taking the production of the waste tire powder modified asphalt product in the present invention as an example, the particle size of the waste tire powder described in the formula is 60 mesh, and the waste tire powder is selected from farm vehicle waste tire powder (NY). The weight of each component is as follows:

[0051] Modified waste tire powder (NY) 22kg

[0052] Zhonghai AH-70# asphalt 78kg

[0053] WJ-1 stabilizer 0.1kg;

[0054] Wherein, the above-mentioned waste tire powder (NY) is composed of the following raw materials in parts by weight: 21.45 kg of waste tire powder (NY), 0.22 kg of diethylenetriamine, 0.22 kg of coal tar, and 0.11 kg of cuprous chloride;

[0055] The 0.1kg WJ-1 stabilizer mentioned above is composed of the following raw materials in parts by weight: sulfur: 0.075kg, rosin 0.019kg, talcum powder 0.005kg, dioctyl phthalate 0.001kg.

[0056] The above-mentioned waste tire powder modified asphalt is prepared by the following method:

[005...

Embodiment 3

[0061] Taking the production of the waste tire powder modified asphalt product in the present invention as an example, the particle size of the waste tire powder described in the formula is 40 mesh, and the waste tire powder is selected from the crown tire powder (TG), each group in the formula The points are weighted as follows:

[0062] Modified crown tire powder (TG) 20kg

[0063] Sinopec 70# asphalt 79kg

[0064] WJ-1 stabilizer 0.1kg;

[0065] Wherein, the above-mentioned modified crown tire powder (TG) is composed of the following raw materials in parts by weight: 17.3 kg of crown tire powder (TG), 0.06 kg of diphenylguanidine, 0.04 kg of cuprous chloride, 2.6 kg of tall oil kg;

[0066] The 0.1kg WJ-1 stabilizer mentioned above is composed of the following raw materials in parts by weight: sulfur: 0.075kg, rosin 0.019kg, talcum powder 0.005kg, dioctyl phthalate 0.001kg.

[0067] The above-mentioned waste tire powder modified asphalt is prepared by the following meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com