Aqueous paint printing ink anti-flash-rust agent, preparation method therefor and applications

A technology of anti-flash rust agent and water-based coating, which is applied in the direction of ink, application, anti-corrosion coating, etc., to achieve stable performance, anti-corrosion, and good anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

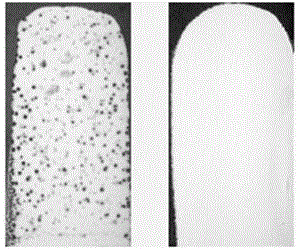

Image

Examples

Embodiment 1

[0054] A kind of anti-flash rust agent for water-based coating ink of the present embodiment is made up of the raw material of following mass percentage:

[0055] Imidazoline compound 20%, alkyl benzotriazole 2%, EDTA compound 3%, alkylamine 1%, deionized water balance.

[0056] Wherein, the imidazoline compound is an alkyl imidazoline quaternary ammonium salt.

[0057] Wherein, the number of carbon atoms of the alkyl group in the alkylbenzotriazole is C3.

[0058] Wherein, the EDTA compound is EDTA.

[0059] Wherein, the alkylamine is a mixture of ethylenediamine, hexamethylenediamine and butylenediamine in a mass ratio of 1:2:3.

[0060] A kind of preparation method of anti-flash rust agent for water-based paint ink of the present embodiment, the imidazoline, alkyl benzotriazole, nitrite, EDTA compound, alkylamine, deionized water of above-mentioned mass percent are mixed completely Dissolved, the anti-flash rust agent can be obtained.

[0061] The application of an anti...

Embodiment 2

[0063] A kind of anti-flash rust agent for water-based coating ink of the present embodiment is made up of the raw material of following mass percentage:

[0064]Imidazoline compound 18%, alkyl benzotriazole 3%, EDTA compound 4%, alkylamine 0.5%, deionized water balance.

[0065] Wherein, the imidazoline compounds are alkyl imidazoline amines.

[0066] Wherein, the number of carbon atoms of the alkyl group in the alkylbenzotriazole is C1.

[0067] Wherein, the EDTA compound is EDTA ammonium salt.

[0068] Wherein, the alkylamine is a mixture of ethylenediamine, hexamethylenediamine and butylenediamine in a mass ratio of 1.5:2:3.5.

[0069] A kind of preparation method of anti-flash rust agent for water-based paint ink of the present embodiment, the imidazoline, alkyl benzotriazole, nitrite, EDTA compound, alkylamine, deionized water of above-mentioned mass percent are mixed completely Dissolved, the anti-flash rust agent can be obtained.

[0070] The application of an anti...

Embodiment 3

[0072] A kind of anti-flash rust agent for water-based coating ink of the present embodiment is made up of the raw material of following mass percentage:

[0073] Imidazoline compound 15%, alkyl benzotriazole 5%, EDTA compound 5%, alkylamine 0.8%, deionized water balance.

[0074] Wherein, the imidazoline compounds are alkyl imidazoline amides.

[0075] Wherein, the number of carbon atoms of the alkyl group in the alkylbenzotriazole is C5.

[0076] Wherein, the EDTA compound is EDTA sodium salt.

[0077] Wherein, the alkylamine is a mixture of n-butylamine and di-n-butylamine in a mass ratio of 2:1.

[0078] A kind of preparation method of anti-flash rust agent for water-based paint ink of the present embodiment, the imidazoline, alkyl benzotriazole, nitrite, EDTA compound, alkylamine, deionized water of above-mentioned mass percent are mixed completely Dissolved, the anti-flash rust agent can be obtained.

[0079] The application of an anti-flash rust agent for water-base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com