UV cured aqueous plastic coating and preparation method thereof

A technology of plastic coating and ultraviolet light, applied in the field of coatings, can solve the problems of poor adhesion and easy falling off, and achieve the effects of small particle size, good adhesion and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

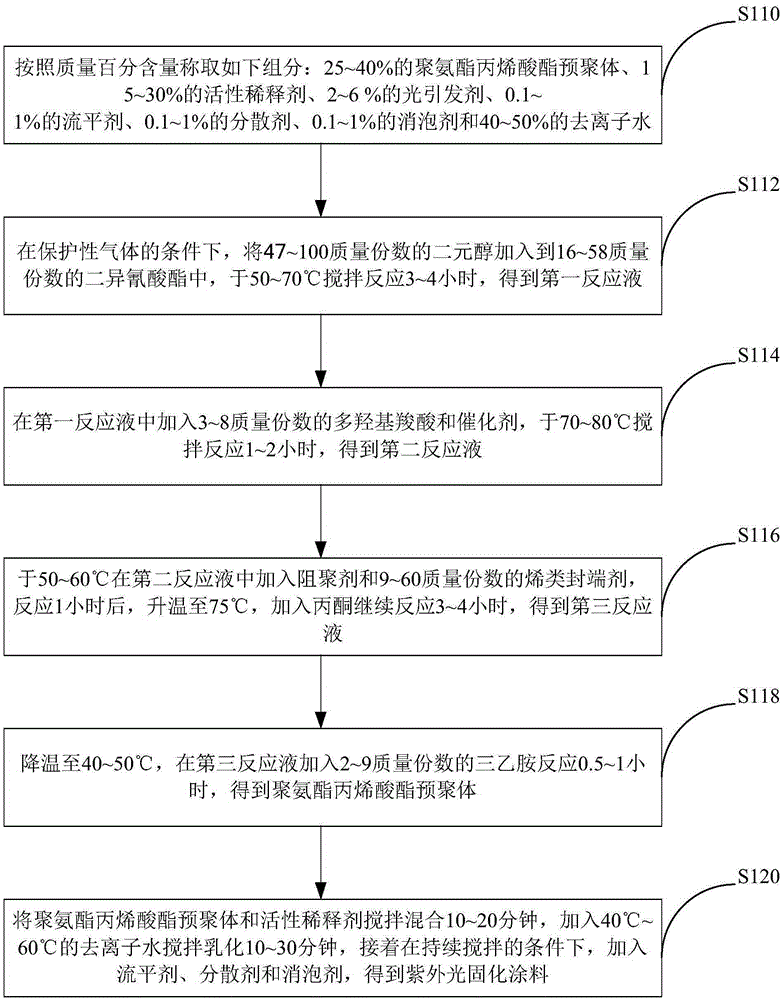

[0043] Such as figure 1 As shown, the preparation method of a UV-curable water-based plastic coating in one embodiment can be used to prepare the above-mentioned UV-curable water-based plastic coating. The preparation method of this ultraviolet curing water-based plastic coating comprises the steps:

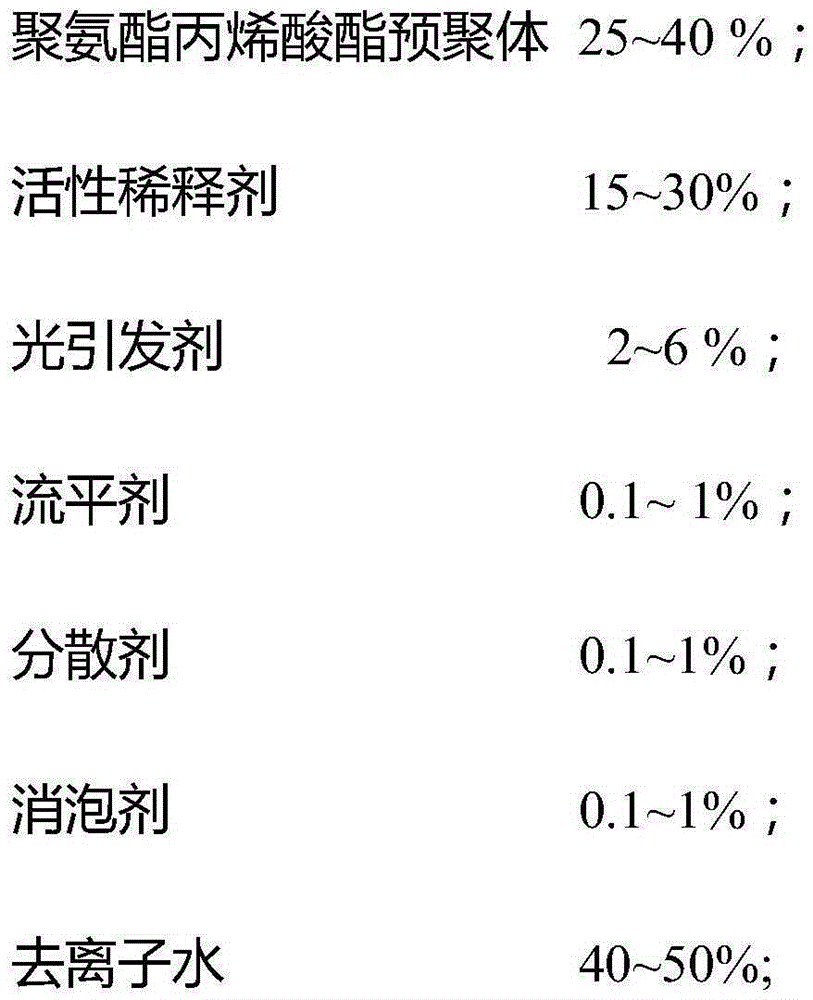

[0044] Step S110: Weigh the following components according to mass percentage: 25-40% polyurethane acrylate prepolymer, 15-30% reactive diluent, 2-6% photoinitiator, 0.1-1% fluid Leveling agent, 0.1-1% dispersant, 0.1-1% defoamer and 40-50% deionized water.

[0045] Among them, the urethane acrylate prepolymer can be purchased. Preferably, the polyurethane acrylate prepolymer is prepared through the following steps:

[0046] Step S112: under the condition of protective gas, add 47-100 parts by mass of dihydric alcohol to 16-58 parts by mass of diisocyanate, stir and react at 50-70°C for 3-4 hours to obtain the first The reaction solution.

[0047] Wherein, the protective gas...

Embodiment 1

[0066] The preparation process of the UV-curable water-based plastic coating of the present embodiment is as follows:

[0067] (1) Preparation of urethane acrylate prepolymer: under the condition of nitrogen, add 25g of toluene diisocyanate to a four-hole round-bottomed reaction flask equipped with a thermometer, a condenser tube and a stirring rod, and 65g of polycaprolactone diisocyanate Slowly add the alcohol dropwise into the round bottom flask, stir and react at 65°C for 3.5h to obtain the first reaction liquid; continue to add 6g of dimethylol propionic acid, and dropwise add 0.1g of dibutyltin dilaurate, stir and react at 75°C 1h; cool down to 60°C, add 6g of hydroxyethyl methacrylate, 6.2g of pentaerythritol triacrylate and 0.07g of polymerization inhibitor, react for 1h, adjust the viscosity with an appropriate amount of acetone, then raise the temperature to 75°C for 4h; cool down to 45°C , add 4.5g of triethylamine, react for 0.5h, and obtain a transparent polyureth...

Embodiment 2

[0072] The preparation process of the UV-curable water-based plastic coating of the present embodiment is as follows:

[0073] (1) Preparation of urethane acrylate prepolymer: under the condition of nitrogen, add 30g of dicyclohexylmethane diisocyanate to a four-necked round-bottom reaction flask equipped with a thermometer, a condenser tube and a stirring rod, and 45g of polyether Dihydric alcohol was slowly added dropwise to the round bottom flask, stirred and reacted at 50°C for 3 hours to obtain the first reaction liquid; continue to add 3 g of dimethylol propionic acid, and dropwise added 0.1 g of dibutyltin dilaurate, and stirred at 70°C for reaction 1h; cool down to 50°C, add 2g of hydroxyethyl acrylate, 9.5g of pentaerythritol triacrylate and 0.07g of polymerization inhibitor, react for 1h, adjust the viscosity with an appropriate amount of acetone, then raise the temperature to 75°C for 3h; cool down to 45°C, add 2.3 g of triethylamine was reacted for 1 hour, and a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com