Method for preparing ternary nitric acid molten salt phase change heat storage material

A phase-change heat storage material and molten salt technology are applied in heat exchange materials, chemical instruments and methods to achieve the effects of low preparation cost, easy realization and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

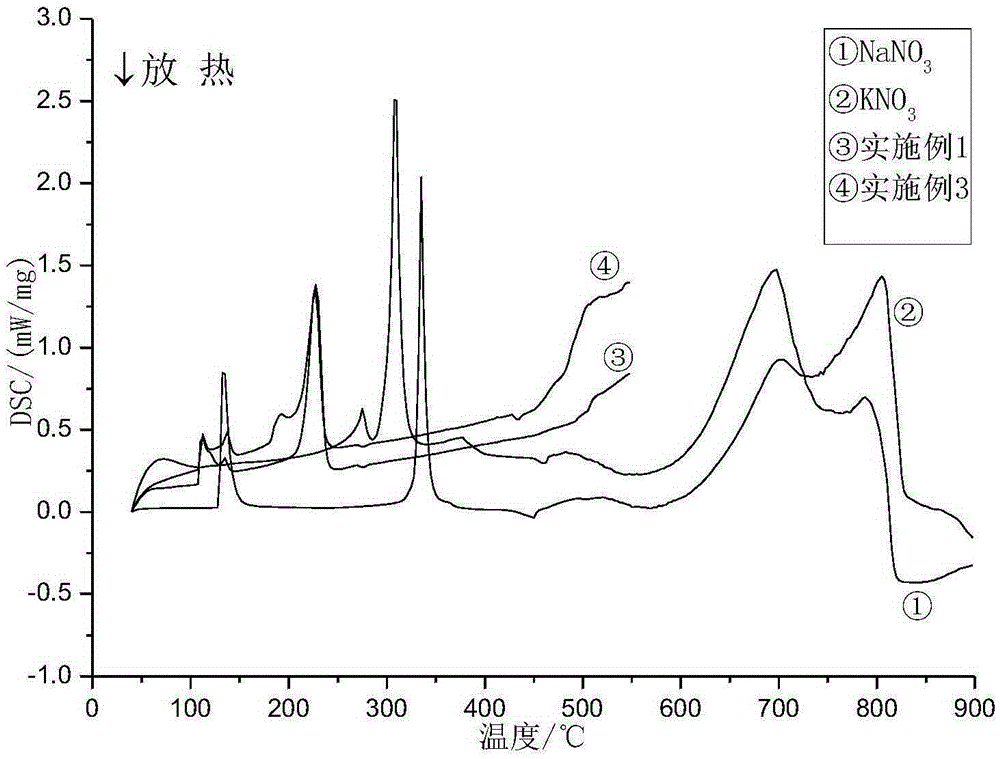

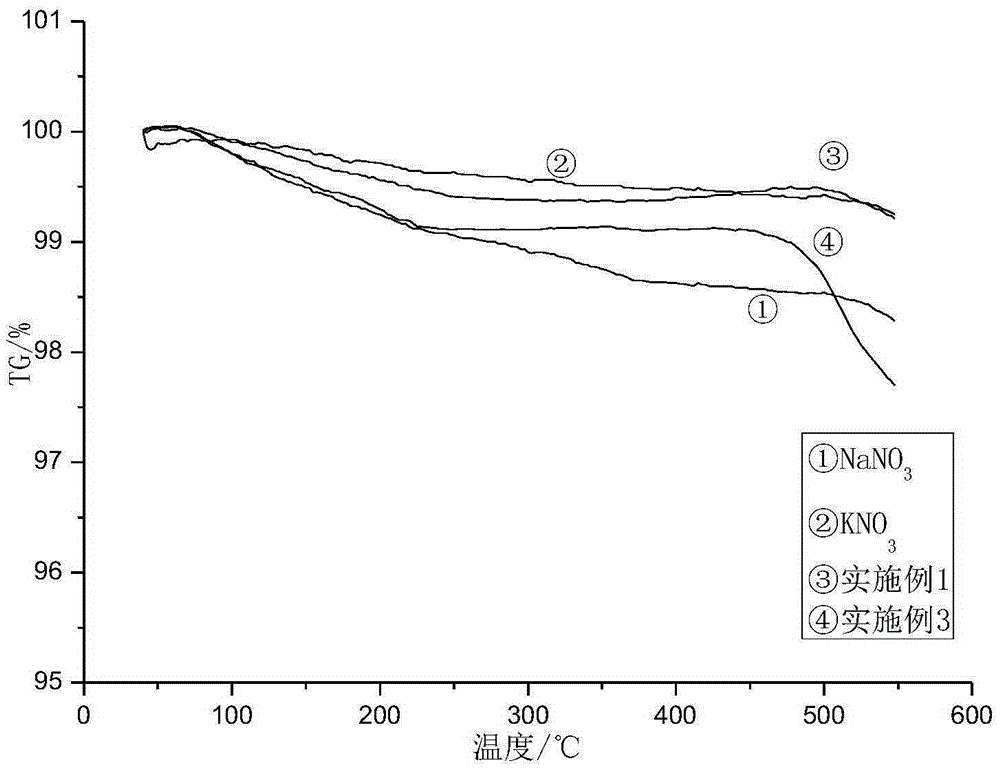

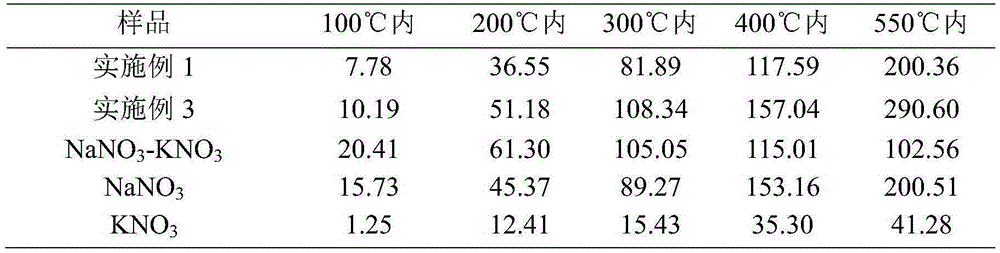

Embodiment 1

[0052] Weigh sodium nitrate, potassium nitrate and neodymium nitrate respectively according to the mass ratio of 54:45:1; wherein, the purity of sodium nitrate, potassium nitrate and salt neodymium nitrate are all greater than 99%, and the sum of impurity ions is less than 1%; the weighed Sodium nitrate is put into mortar, adopts mechanical grinding mode to grind 35min, waits to pass through sieve (average aperture of sieve is 1mm) after grinding, obtains sodium nitrate powder; Grind in a mortar for 35 min, and pass through a sieve (the average aperture of the sieve is 1 mm) after the grinding is completed to obtain potassium nitrate powder; put the neodymium nitrate taken into a mortar, grind for 35 min in a mechanical grinding mode, and pass through a sieve ( The average aperture of the sieve is 1 mm) to obtain neodymium nitrate powder; the sodium nitrate powder, potassium nitrate powder and neodymium nitrate powder are placed in a vacuum drying oven for drying independently,...

Embodiment 2

[0056] Weigh sodium nitrate, potassium nitrate and neodymium nitrate respectively according to the mass ratio of 53:44:3; wherein, the purity of sodium nitrate, potassium nitrate and salt neodymium nitrate are all greater than 99%, and the sum of impurity ions is less than 1%; the weighed Sodium nitrate is put into mortar, adopts mechanical grinding mode to grind 40min, passes through sieve (average aperture of sieve is 2mm) after grinding, obtains sodium nitrate powder; Grind for 40min, pass through a sieve (the average aperture of the sieve is 2mm) after the completion of the grinding, and obtain potassium nitrate powder; put the neodymium nitrate taken by weight into a mortar, grind for 40min by mechanical grinding, pass through a sieve (sieve) after the completion of the grinding The average pore diameter is 2mm), to obtain neodymium nitrate powder; the sodium nitrate powder, potassium nitrate powder and neodymium nitrate powder are independently placed in a vacuum drying o...

Embodiment 3

[0060] Weigh sodium nitrate, potassium nitrate and neodymium nitrate respectively according to the mass ratio of 52:43:5; wherein, the purity of sodium nitrate, potassium nitrate and salt neodymium nitrate are all greater than 99%, and the sum of impurity ions is less than 1%; Sodium nitrate is put into the mortar, adopts mechanical grinding mode to grind 45min, passes through the sieve (the average aperture of sieve is 1.5mm) after the grinding is finished, obtains sodium nitrate powder; The grinding mode grinds for 45min, and passes through a sieve (the average aperture of the sieve is 1.5mm) after the grinding is completed to obtain potassium nitrate powder; the neodymium nitrate taken by weighing is put into a mortar, and the mechanical grinding method is used to grind for 45min, and after the grinding is completed, pass Sieve (the average aperture of the sieve is 1.5mm) to obtain neodymium nitrate powder; sodium nitrate powder, potassium nitrate powder and neodymium nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com