Method for extracting rose essential oil through combination of ultrahigh pressure and steam distillation

A technology of steam distillation and rose essential oil, which is applied in the directions of essential oil/spice, fat generation, etc., can solve the problems of increased impurity content lost by thermal decomposition, increased methyl eugenol content, poor wall breaking effect, etc. Larger, higher yield, lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

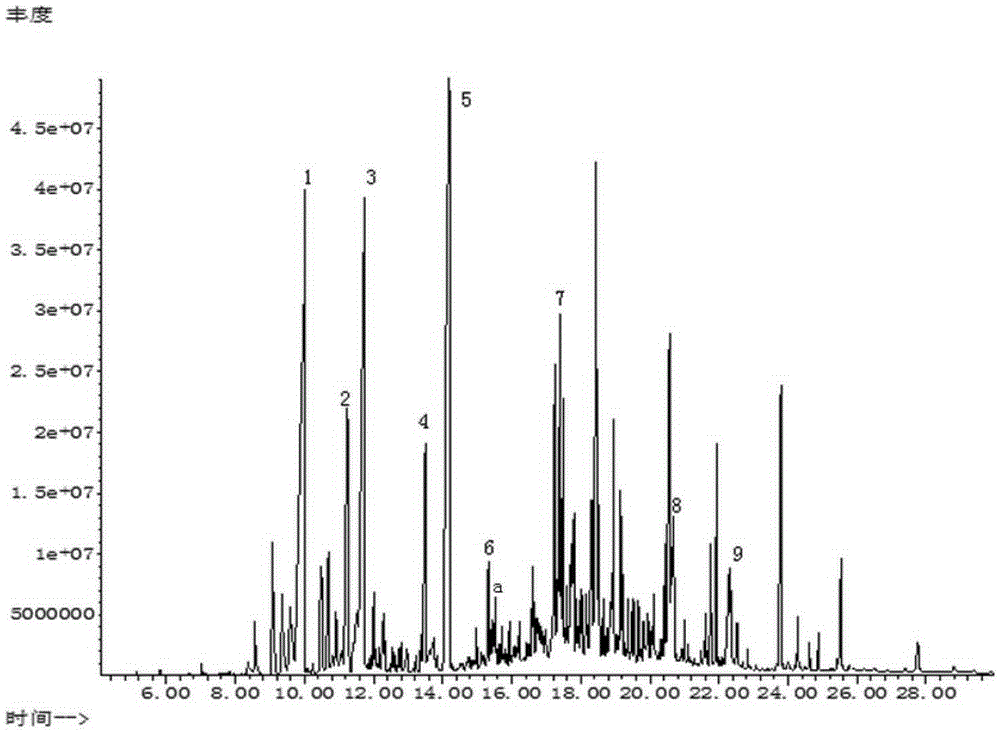

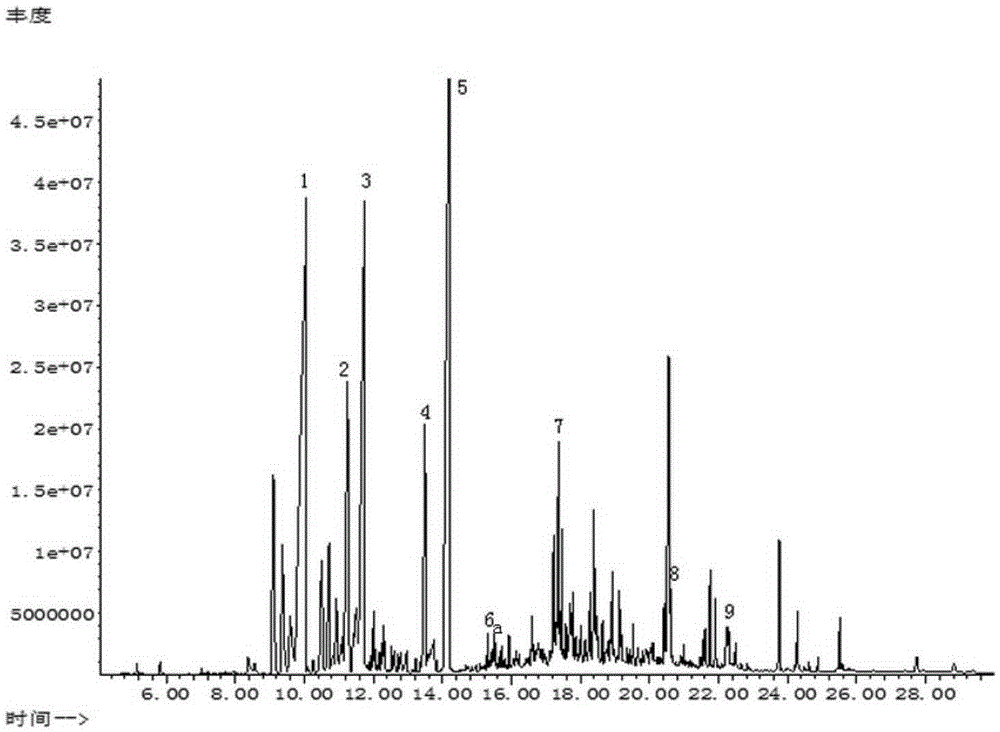

Method used

Image

Examples

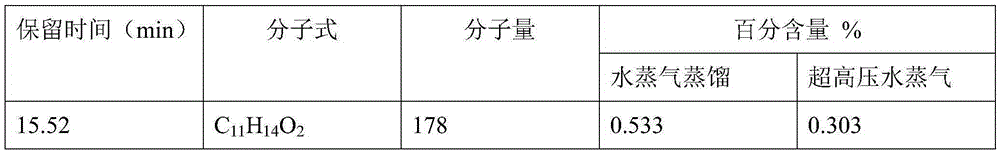

Embodiment 1

[0036]For fresh Pingyin roses, add a citric acid aqueous solution with a mass concentration of 0.5% at a ratio of material to liquid ratio of 1.0:2.0 (by weight), mix evenly, seal a polyethylene retort bag at the level of the liquid surface, and place under pressure Ultrasonic extraction kettle; pressure 500MPa, holding time 6min, temperature 25°C. After the end of the ultra-high pressure, put the material liquid in the sealed bag into the distillation bottle for steam distillation, and use deionized water as the steam source; control the heating temperature to 102°C to ensure the continuous and stable output of water vapor; set the distillation bottle The heat preservation temperature is 99°C to control the evaporation rate in the distillation bottle; the cooling water circulation device is used to control the flow rate and temperature of the condensed water to control the condensation rate; the distillation time is 2h; the first drop of distillate flowing out from the condens...

Embodiment 2

[0045] For fresh Pingyin roses, add a citric acid aqueous solution with a mass concentration of 1% at a ratio of material to liquid ratio of 1.0:1.5 (by weight), mix evenly, seal the cooking bag at the level of the liquid level, and place it under pressure for ultrasonic extraction In the kettle; the pressure is 300MPa, the holding time is 8min, and the temperature is 30°C. After the end of the ultra-high pressure, put the material liquid in the sealed bag into the distillation bottle for steam distillation. Deionized water is used as the steam source; the heating temperature is controlled to 102°C to ensure the continuous and stable output of water vapor; the heat preservation temperature of the distillation flask is set to 99°C to control the evaporation rate in the distillation flask; the cooling water circulation device is used to control the flow rate of condensed water and temperature to control the condensation rate; the distillation time is 2h; the first drop of distil...

Embodiment 3

[0049] For fresh Pingyin roses, add a citric acid aqueous solution with a mass concentration of 2% at a ratio of material to liquid ratio of 1.0:2.5 (by weight), mix well, seal the retort bag at the level of the liquid level, and place it under pressure for ultrasonic extraction In the kettle; the pressure is 100MPa, the holding time is 6min, and the temperature is 30°C. After the end of the ultra-high pressure, put the material liquid in the sealed bag into the distillation bottle for steam distillation. Deionized water is used as the steam source; the heating temperature is controlled to 102°C to ensure the continuous and stable output of water vapor; the heat preservation temperature of the distillation flask is set to 99°C to control the evaporation rate in the distillation flask; the cooling water circulation device is used to control the flow rate of condensed water and temperature to control the condensation rate; the distillation time is 2h; the first drop of distillat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com