Preparation method of electrospun composite membrane for lithium ion battery

A lithium-ion battery, electrospinning technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of limiting battery ionic conductivity, poor thermal dimensional stability, battery short-circuit, etc., to improve ion conduction. ability and tensile strength and elongation at break, high ionic conductivity and safety properties, the effect of compensating for the weakening of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

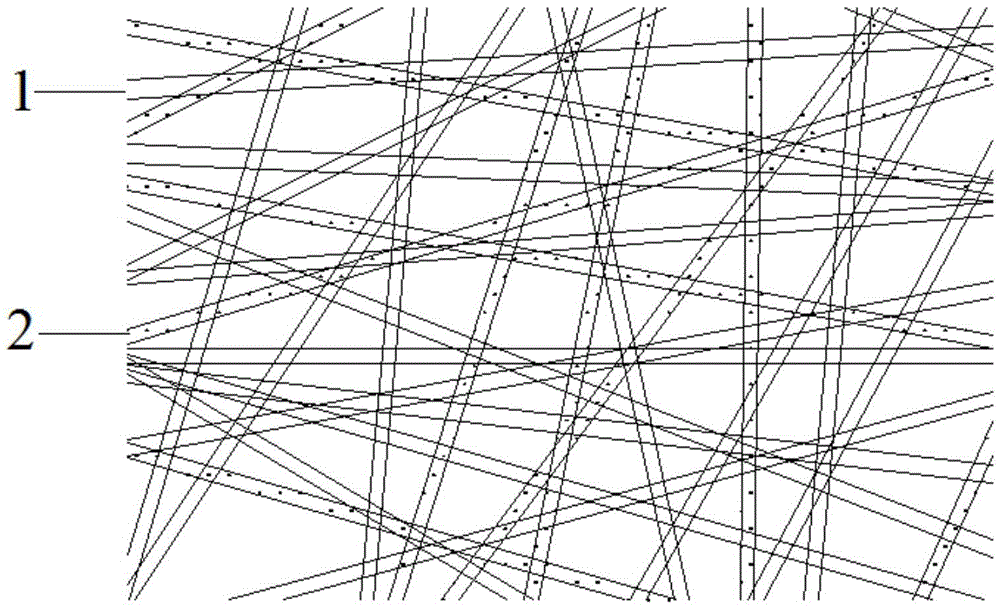

Image

Examples

Embodiment Construction

[0019] The electrospinning composite diaphragm for lithium ion battery described in this embodiment and the preparation method thereof comprise the following steps:

[0020] (1) preparation mass fraction is the precursor solution of 10%, wherein the quality of PVDF is 2.55g, another kind of polymkeric substance is PMMA, and quality is 0.45g, and solvent is the mixture of DMAc and acetone, and wherein DMAc volume is 20ml, acetone The volume is 10ml. A magnetic stirrer was used to stir at room temperature for 12 hours to obtain a uniformly mixed precursor solution.

[0021] (2) preparation mass fraction is the precursor solution of 10%, wherein the quality of PVDF is 3g, and inorganic nanomaterial is SiO 2 , the average diameter of nanoparticles is 15nm, and the mass is 0.3g. First use an ultrasonic cleaning machine to ultrasonically contain solvent and nano-SiO 2 The solution was added for 30 minutes, then PVDF powder was added, and a magnetic stirrer was used to stir at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com