A kind of vegetable soft capsule rubber composition and preparation method thereof

A soft capsule and plant-based technology, which is applied in the field of plant-based soft capsule rubber composition and its preparation, can solve the problems of rubber elasticity and toughness deviation, high price of pullulan polysaccharide, and high cost, and achieve low friability, The effect of abundant sources and excellent cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

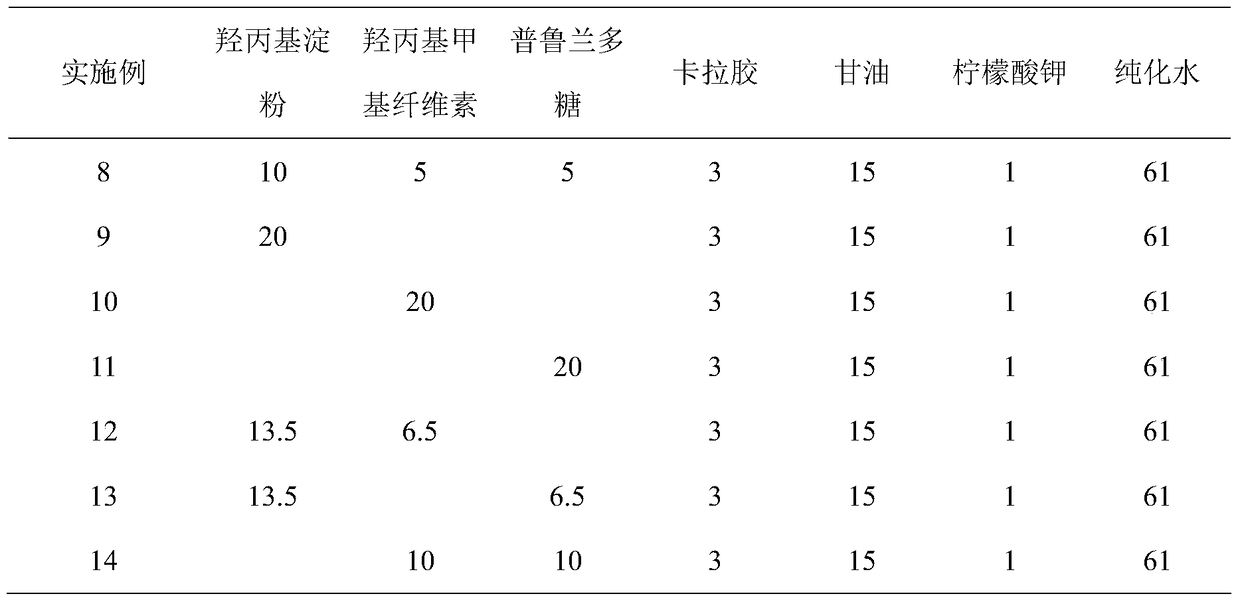

Examples

Embodiment 1

[0034] By mass percentage, the group distribution ratio is as follows:

[0035] Hydroxypropyl starch: 15%;

[0036] Hydroxypropyl methylcellulose: 7%;

[0037] Pullulan: 5%;

[0038] Carrageenan: 2%;

[0039] Glycerol: 7%;

[0040] Polyethylene glycol 400: 5%;

[0041] Potassium citrate: 0.2%;

[0042] Titanium dioxide: 0.5%;

[0043] Purified water: 58.3%.

[0044] The hydroxypropyl starch is dissolved and dispersed in purified water of the same amount as the hydroxypropyl starch, and heated in a 55° C. water bath to obtain solution A. The remaining components except the hydroxypropyl starch were added to the remaining purified water to disperse evenly, and the solution B was obtained by heating and dissolving in a 65°C water bath for 20min. Add solution A to solution B, stir and mix well, then gradually heat to 90 °C, keep the temperature for 1.5 hours, then cool down to 75 °C, keep warm and defoaming for 3 hours, and directly pass through the glue feeding equipment ...

Embodiment 2

[0046] By mass percentage, the group distribution ratio is as follows:

[0047] Hydroxypropyl starch: 15%;

[0048] Hydroxypropyl methylcellulose: 8%;

[0049] Pullulan: 4.5%;

[0050] Gellan Gum: 2%;

[0051] Glycerin: 8%;

[0052] Sorbitol: 4%;

[0053] Sodium alginate: 1%;

[0054] Carboxymethyl cellulose: 0.2%;

[0055] Potassium citrate: 0.2%;

[0056] Paprika: 0.1%;

[0057] Purified water: 57%.

[0058] The hydroxypropyl starch was dissolved and dispersed in purified water of the same amount as the hydroxypropyl starch, and heated and kept warm in a 60° C. water bath to obtain solution A. The remaining components except hydroxypropyl starch were added to the remaining purified water to disperse evenly, and the solution B was obtained by heating and dissolving in a 60°C water bath for 30min. Add solution A to solution B, stir and mix well, then gradually heat to 95°C, keep warm for 2 hours, then cool to 80°C, keep warm and defoamed for 2 hours. , to prepare soft...

Embodiment 3

[0060] By mass percentage, the group distribution ratio is as follows:

[0061] Hydroxypropyl starch: 15%;

[0062] Hydroxypropyl methylcellulose: 8%;

[0063] Pullulan: 4%;

[0064] Carrageenan: 1.5%;

[0065] Gellan Gum: 1%;

[0066] Glycerin: 10%;

[0067] Sorbitol: 4%;

[0068] Carboxymethyl cellulose: 0.2%;

[0069] Potassium citrate: 0.2%;

[0070] Titanium dioxide: 1%;

[0071] Paprika: 0.5%;

[0072] Purified water: 54.6%.

[0073] The hydroxypropyl starch is dissolved and dispersed in purified water of the same amount as the hydroxypropyl starch, and heated in a 65° C. water bath to obtain solution A. The remaining components except hydroxypropyl starch were added to the remaining purified water to disperse evenly, and the solution B was obtained by heating and dissolving in a 55°C water bath for 50min. Add solution A to solution B, stir and mix well, then gradually heat to 90°C, keep the temperature for 0.5h, then cool down to 75°C, keep warm and defoaming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com