Composite nano filtration membrane with high selectivity on removing divalent ions and preparation method thereof

A composite nanofiltration membrane and high-selectivity technology, which is applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as the performance difference of nanofiltration membranes, and achieve the effect of improving selective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A composite nanofiltration membrane with high selectivity for the removal of divalent ions, which consists of a non-woven fabric layer, a polysulfone porous support layer, a cross-linked desalination layer and a charge-grafted functional layer, wherein the polysulfone porous support layer It is arranged on the non-woven fabric layer, and the cross-linked desalination layer and the charged grafted functional layer are sequentially arranged on the polysulfone porous support layer; the cross-linked desalination layer is prepared by reacting the amine mixture and the acid chloride monomer mixture at the oil-water phase interface; The electrografting functional layer is grafted on the cross-linked desalination layer through surface chemistry. The amine mixture is formed by mixing aliphatic amines and aromatic amines; the acyl chloride monomer mixture is formed by mixing acyl chloride monomers with bifunctionality and acyl chloride monomers with trifunctionality in any ratio. ...

Embodiment 2- Embodiment 6

[0058] On the basis of embodiment 1, other changes on the basis of embodiment 1 are as follows:

[0059]

[0060]

[0061]

Embodiment 7

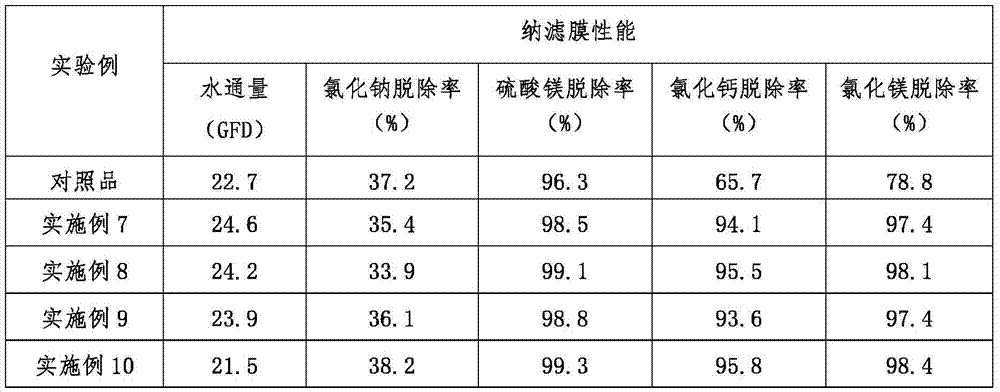

[0064] A 19% polysulfone solution is prepared, and a porous polymer support layer is prepared by a liquid-solid phase conversion method. A solution containing 0.5 wt% hexamethylenediamine and 2.0% m-phenylenediamine was prepared, and an appropriate amount of NaOH was added to adjust the pH value to about 11 to obtain a mixed amine solution (A solution). A 0.22 wt% trimesoyl chloride solution (solution B) was prepared, wherein the solvent was cyclohexane. Prepare 0.3% glycerol ether aqueous solution (C solution), the catalyst is hydrochloric acid, the concentration is 0.05%. Soak the polysulfone porous support layer in solution A for 30 s, drain the water droplets on the membrane surface, and then enter solution B for 20 s, take it out and dry it at room temperature to remove the cyclohexane on the membrane surface. The cyclohexane-removed membrane was placed in solution C, soaked for 50s, and then taken out in an oven at 80°C for heat treatment for 5 minutes. Take out the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com