A kind of preparation method of sea urchin-shaped rutile nano-titanium oxide

A nano-titanium oxide, rutile-type technology is applied in the fields of environmental protection and clean energy, can solve the problem of not getting titanium dioxide, etc., and achieves the effects of avoiding high-temperature calcination steps, uniform morphology, and easily controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

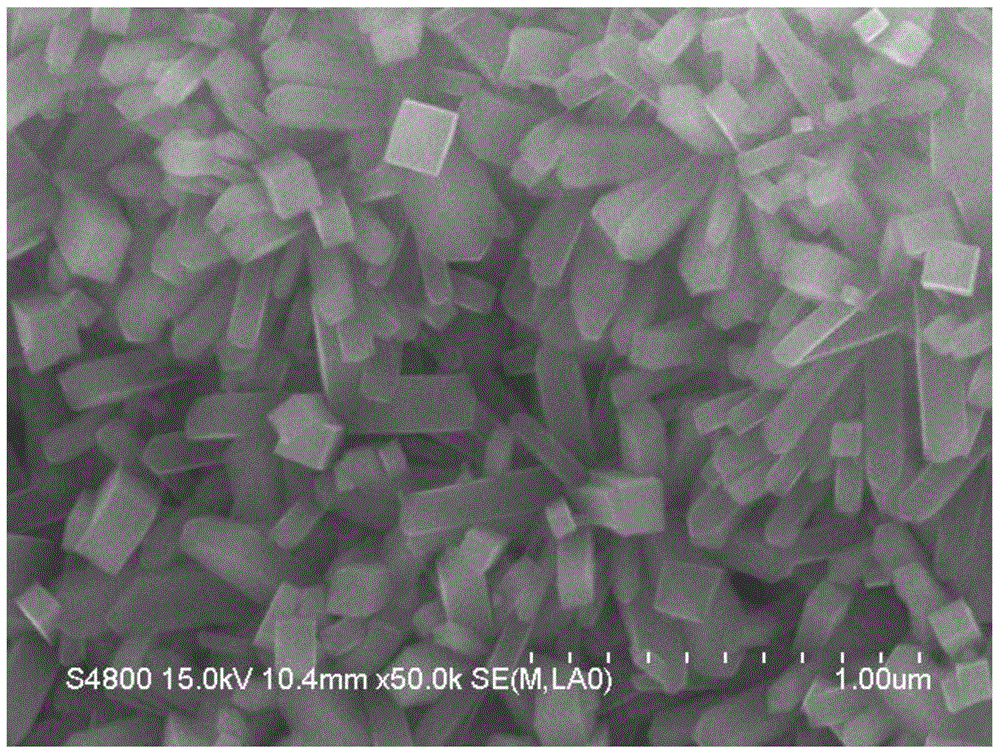

[0039] A preparation method of sea urchin-shaped rutile nano-titanium oxide, comprising the following steps: adding 0.032g of titanium silicide, 0.5ml of concentrated hydrochloric acid, and 29.5ml of deionized water into a tetrafluoroethylene reactor in sequence, stirring for 2 to 3 hours, and stirring at 180 Keep warm in an oven at ℃ for 18 hours, discharge, centrifuge, wash the separated precipitate with alcohol and deionized water alternately for 3 times, dry at 80℃ for 4 hours, and the distance from the farthest end to the center of a single particle of the finished product is about 400nm , the crystal form is rutile. The scanning electron micrographs of the synthesized titanium dioxide particles are shown in image 3 .

Embodiment 2

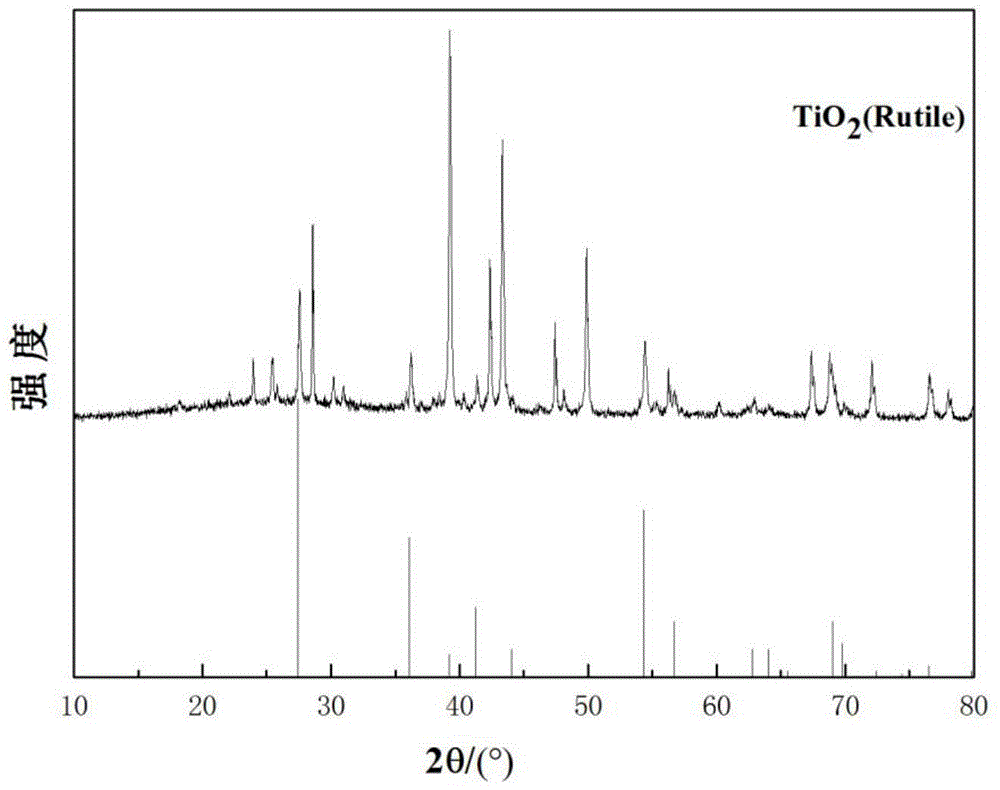

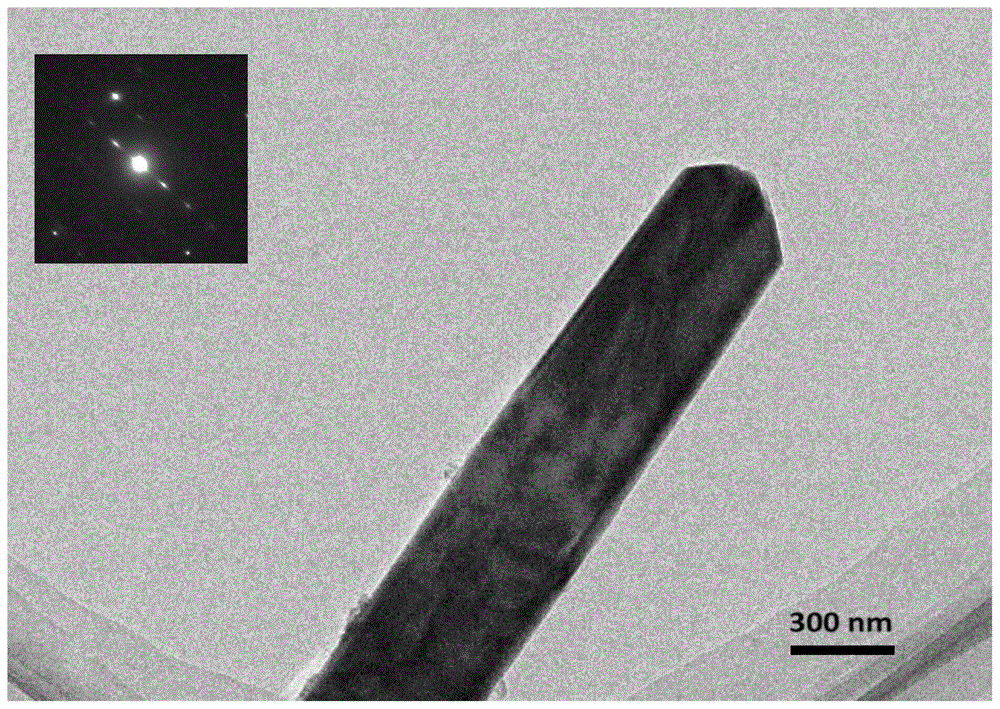

[0041]A preparation method of sea urchin-shaped rutile nano-titanium oxide, comprising the following steps: adding 0.032g of titanium silicide, 1.5ml of concentrated hydrochloric acid, and 28.5ml of deionized water into a tetrafluoroethylene reaction kettle in sequence, stirring for 2 to 3 hours, and stirring at 180 Keep warm in an oven at ℃ for 18 hours, discharge, centrifuge, wash the separated precipitate with alcohol and deionized water alternately for 3 times, and dry at 80℃ for 4 hours. Micron or so, the crystal form is rutile. The XRD patterns of the synthesized titanium dioxide particles are shown in figure 1 , the transmission electron microscope photo see Figure 4 .

Embodiment 3

[0043] A preparation method of sea urchin-shaped rutile nano-titanium oxide, comprising the following steps: adding 0.032g of titanium silicide, 2.5ml of concentrated hydrochloric acid, and 27.5ml of deionized water into a tetrafluoroethylene reactor in sequence, stirring for 2 to 3 hours, and stirring at 180 Keep warm in an oven at ℃ for 18 hours, discharge, centrifuge, wash the separated precipitate with alcohol and deionized water alternately for 3 times, dry at 80℃ for 4 hours, and the distance from the farthest end to the center of a single particle of the finished product is 2 microns Left and right, the crystal form is rutile. The transmission electron microscope pictures of the synthesized titanium dioxide particles are shown in Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com