Method for quickly preparing NaYF:Yb/Er upconversion nano particles having different phases

A nanoparticle and phase technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as trouble, toxicity of reaction by-products, high reaction temperature, etc., and achieve simple and fast operation, simple post-processing of products, dispersion good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] With 1.0mmol (the total amount of three substances) of Y (NO 3 ) 3 , Yb(NO 3 ) 3 and Er(NO 3 ) 3 Dissolve in 14mL ethanol solution according to stoichiometric ratio 78:20:2, add 3.0mmol NaF solution, stir for 10min, then add 0.342gNH 4 HF 2 , continue to stir for 30 minutes, transfer to a hydrothermal reaction kettle, react at 140°C for 48 hours, naturally cool to room temperature, centrifuge and wash with deionized water and absolute ethanol three times alternately, and obtain β‐NaYF after drying 4 : Yb / Er upconverting nanoparticles.

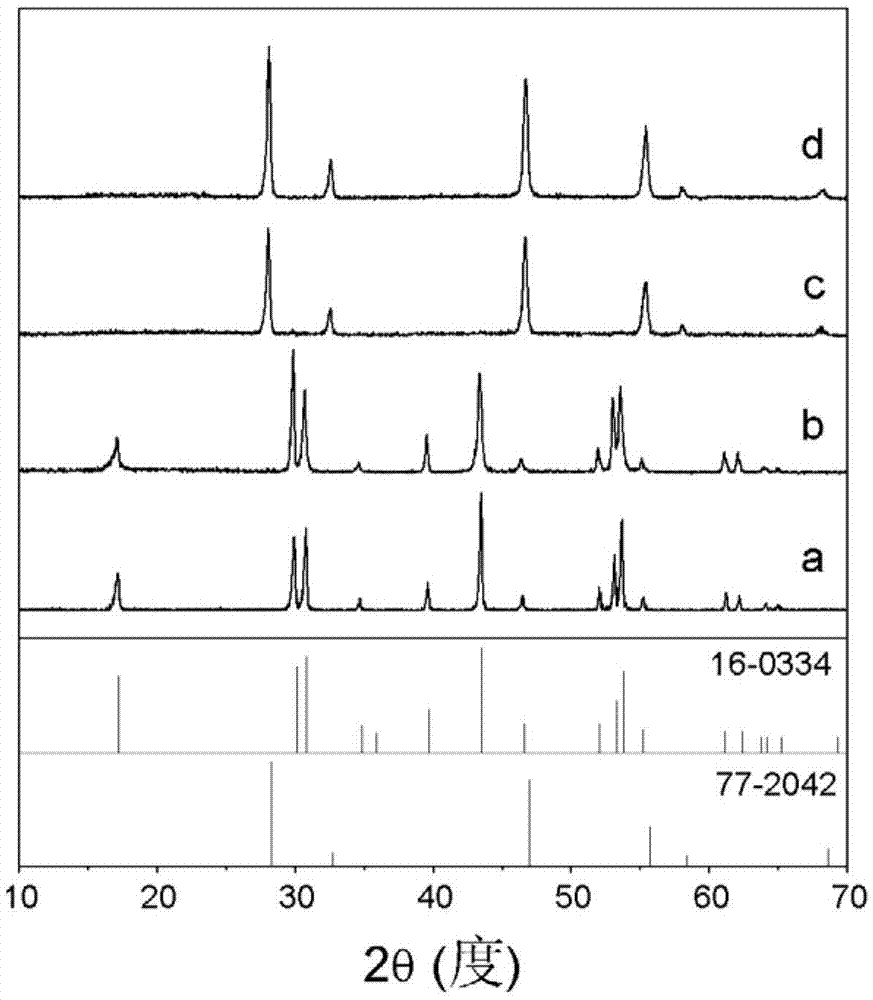

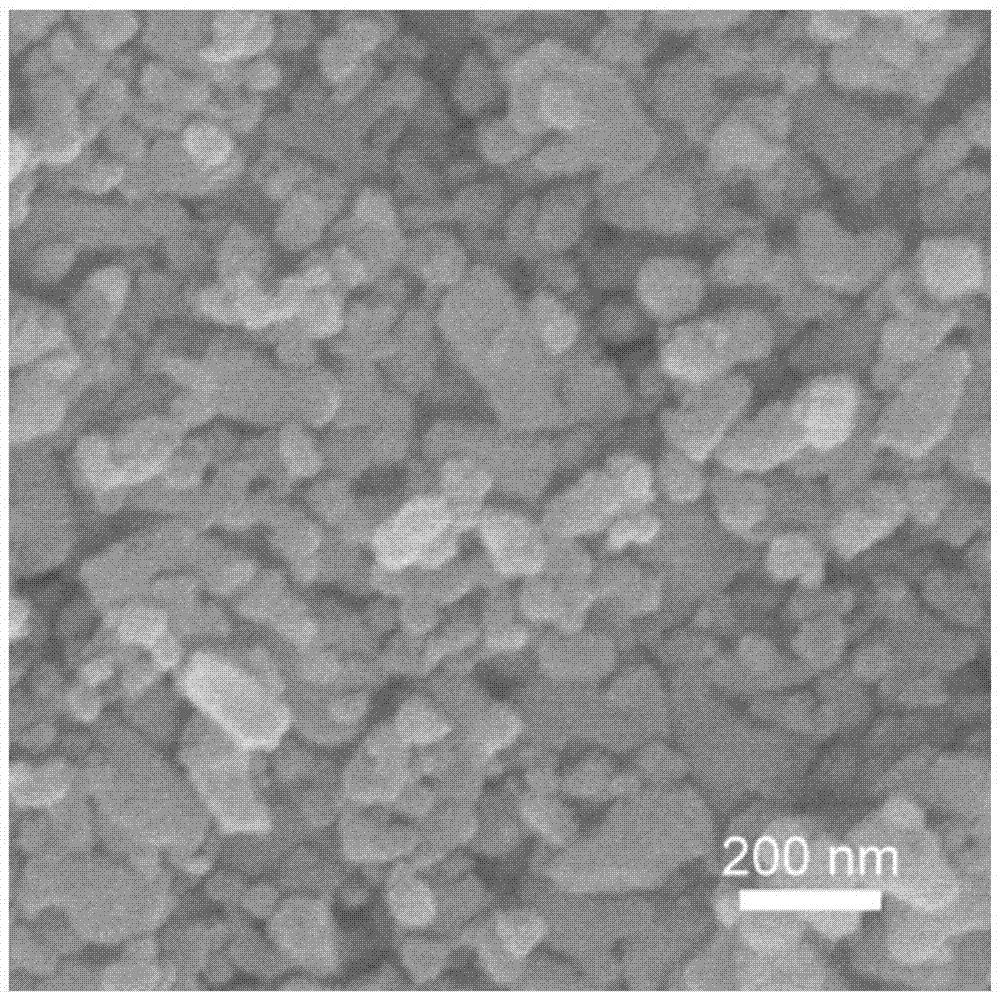

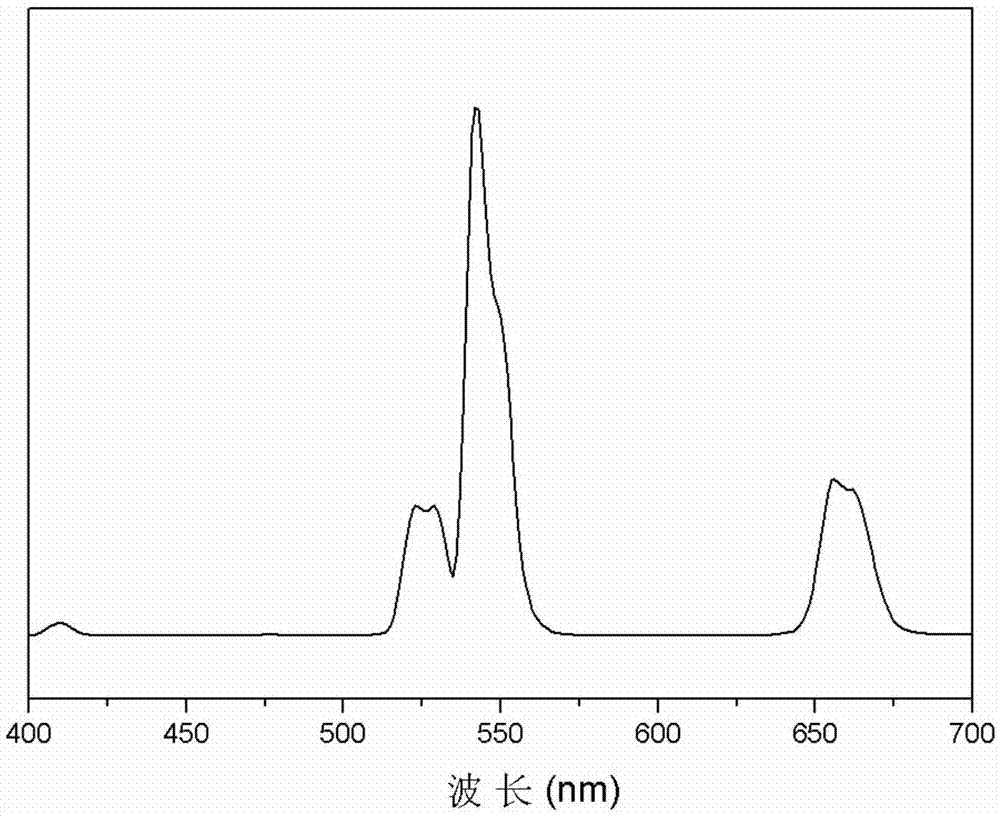

[0027] The XRD diffraction peaks of the product are as figure 1 As shown in the middle curve a, the shape is as figure 2 As shown, its up-conversion luminescence performance is as image 3 shown. From figure 1 It can be seen from the middle curve a that all diffraction peaks are consistent with β‐NaYF 4 Corresponding to the standard diffraction peak (JCPDS16‐0334).

[0028] From figure 2 It can be seen from the SEM photos...

Embodiment 2

[0031] 0.2mmol of Y (NO 3 ) 3 , Yb(NO 3 ) 3 and Er(NO 3 ) 3 Dissolve in 14mL propanol solution according to stoichiometric ratio 78:20:2, add 0.6mmol NaF solution, stir for 10min, then add 0.068gNH 4 HF 2 , continue to stir for 30 minutes, transfer to a hydrothermal reaction kettle, react at 180°C for 24 hours, naturally cool to room temperature, centrifuge and wash with deionized water and absolute ethanol three times alternately, and obtain β-NaYF after drying 4 : Yb / Er upconverting nanoparticles.

[0032] The XRD diffraction peaks of the product are as figure 1 Shown in curve b. From figure 1 It can be seen from the middle curve b that all the diffraction peaks are consistent with β‐NaYF 4 Corresponding to the standard diffraction peak (JCPDS16‐0334).

Embodiment 3

[0034] 0.5mmol of Y(NO 3 ) 3 , Yb(NO 3 ) 3 and Er(NO 3 ) 3 Dissolve in 14mL acetic acid solution according to the stoichiometric ratio of 78:20:2, add 1.5mmol of NaF solution, stir for 10min, then add 0.171gNH 4 HF2 , continue to stir for 30 minutes, transfer to a hydrothermal reactor, react at 180°C for 24 hours, cool to room temperature naturally, centrifuge and wash with deionized water and absolute ethanol three times alternately, and obtain α-NaYF after drying 4 : Yb / Er upconverting nanoparticles.

[0035] The XRD diffraction peaks of the product are as figure 1 As shown in the middle curve c, the shape is as Figure 4 shown. From figure 1 It can be seen from the middle curve c that all the diffraction peaks are consistent with α‐NaYF 4 Corresponding to the standard diffraction peak (JCPDS77‐2042). From Figure 4 It can be seen from the SEM photos in the figure that the product is nanoparticles with a size of about 100-150 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com