High-concentration continuous dynamic anaerobic fermentation apparatus for multi-element material and application thereof

An anaerobic fermentation and anaerobic fermentation tank technology, which is applied in the field of high-concentration continuous dynamic anaerobic fermentation devices for multiple materials, can solve the problems of complicated material humidification and spraying process, heavy cleaning workload, and high moisture content of biogas residues. Prevent local acidification problems, realize zero discharge of biogas slurry, and improve the effect of material mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

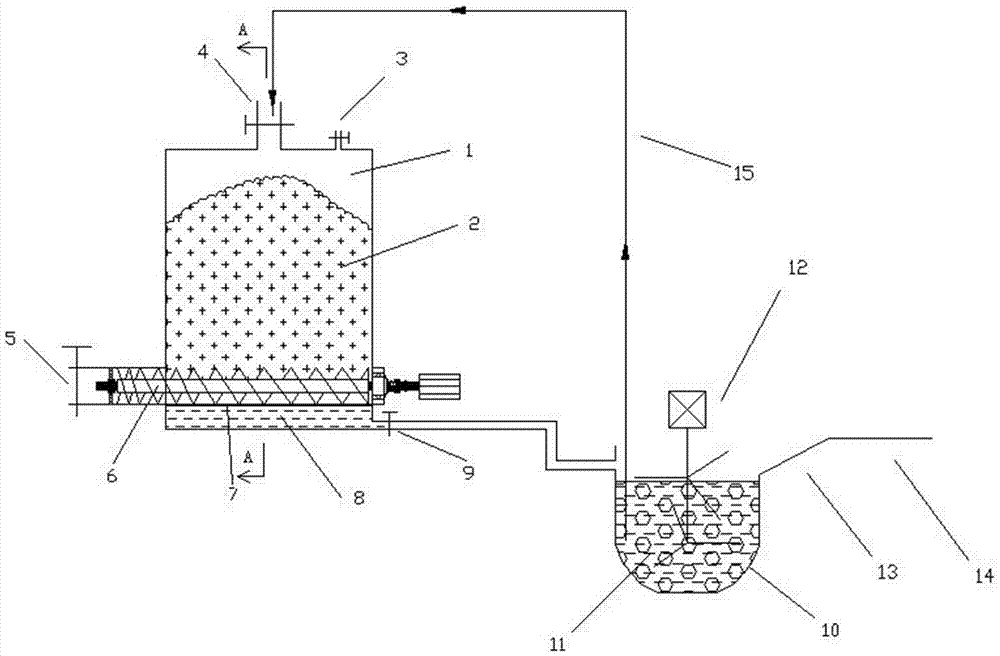

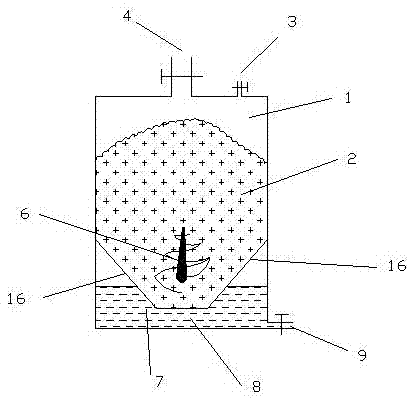

[0021] The accompanying drawings disclose the specific structure of the embodiment of the present invention without limitation, and this embodiment will be further described below in conjunction with the accompanying drawings.

[0022] Depend on figure 1 It can be seen that the high-concentration continuous dynamic anaerobic fermentation device for multi-component materials includes a slurry mixing tank 10 and an anaerobic fermentation tank 1. The slurry mixing tank 10 is an open mixing area. The slurry mixing tank 10 is provided with a biogas slurry inlet and is equipped with a stirring Device 12; the anaerobic fermentation tank 1 is a closed tank body, and the anaerobic fermentation tank 1 is divided into an anaerobic fermentation area and a biogas slurry storage area by a filter screen 7, or a porous filter plate 16, or a partition formed by their combination, and the partition The top of the anaerobic fermentation zone is the anaerobic fermentation zone; the feed port 4 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap