Preparation method for ultrasound-assisted fiber surface expanding of nonwoven cloth and loading with nano zinc oxide

A nano-zinc oxide, non-woven fabric technology, applied in fiber treatment, light-resistant fibers, textiles and papermaking, etc., can solve problems such as environmental pollution, violation of purified water quality, etc., and achieve low cost, easy control, and simple and easy-to-operate preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

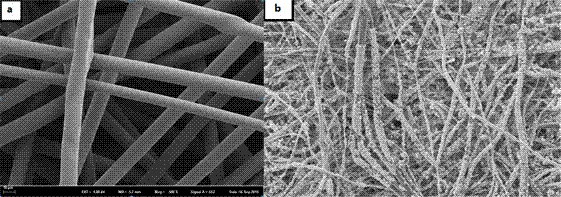

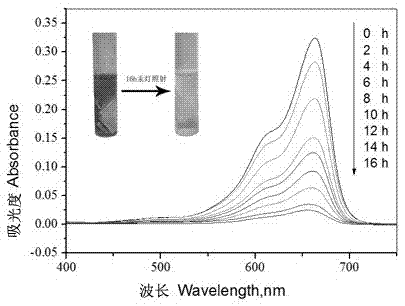

Embodiment 1

[0029]The CNC suspension with a solid content of 20g / L and the zinc chloride solution with a concentration of 0.2mol / L are uniformly mixed at a volume ratio of 33:100, and introduced into a 200W ultrasonic generator. Put 0.2g of PP non-woven fabric into the above mixed solution, heat and ultrasonic at 90°C for 1 hour, and obtain a non-woven fabric with puffed fiber surface. After the reaction, take out the nonwoven fabric; and soak it in NaOH solution (0.5mol / L) for 0.6h, take it out and dry it at 60°C for 5h. Put the dried PP non-woven fabric into the zinc-ammonia solution with a pH of 10.6 and soak it alternately in hot and cold for 40 cycles (the total time is 1h), and then dry it at 100°C for 1h after taking it out, and then obtain the PP non-woven fabric uniformly loaded with nano-zinc oxide on the surface. Woven cloth. The weight of PP nonwovens increased by 36.6% after treatment, and the degradation rate of photocatalytic degradation dyes reached 94.8%. Scanning elect...

Embodiment 2

[0031] The CNC suspension with a solid content of 40g / L and the zinc chloride solution with a concentration of 0.5mol / L are uniformly mixed at a volume ratio of 4:100, and introduced into a 1000W ultrasonic generator. Put 0.5g of PET non-woven fabric into the above mixed solution, heat and ultrasonic at 95°C for 1 hour, and obtain a non-woven fabric with puffed fiber surface. After the reaction is over, take out the nonwoven fabric; soak it in KOH solution (0.2mol / L) for 0.5h, take it out and dry it at 115°C for 1h. Put the dried PET non-woven fabric into the zinc ammonia solution with pH 11.3 and alternately dip it in hot and cold for 10 cycles (the total time is 0.6h), and then dry it at 105°C for 1.5h after taking it out, and then the surface can be uniformly loaded with nano-zinc oxide. PET nonwoven fabric. The weight of PET nonwoven fabric increased by 28.2% after treatment, and the degradation rate of photocatalytic degradation dye reached 90.2%. The diameter of the na...

Embodiment 3

[0033] The CNC suspension with a solid content of 50g / L and the zinc nitrate solution with a concentration of 0.5mol / L were uniformly mixed at a volume ratio of 23:100, and introduced into a 2000W ultrasonic generator. Put 1 g of PP nonwoven fabric into the above mixed solution, heat and ultrasonically heat at 92° C. for 1 hour, and obtain a nonwoven fabric with puffed fiber surface. After the reaction is over, take out the nonwoven fabric; and put it in Ca(OH) 2 Soak in the solution (0.1mol / L) for 0.5h, take it out and dry it at 85°C for 4h. Put the dried PP non-woven fabric into the zinc-ammonia solution with a pH of 10.2 and soak it alternately in hot and cold for 50 cycles (the total time is 2 hours). After taking it out, dry it at 110°C for 1 hour to obtain a PP non-woven fabric uniformly loaded with nano-zinc oxide on the surface. Woven cloth. The weight of PP nonwoven fabric increased by 37.5% after treatment, and the degradation rate of photocatalytic degradation dye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com