Efficient adsorbent based on michelia chapensis leaves and preparation method thereof

An adsorbent, leaf technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc. The effect of low energy consumption, simple preparation process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Lechang Michelia leaves are crushed into powder, sieved, and the leaf powder with a size below 300 microns is taken for subsequent use;

[0019] (2) Utilize the sodium hydroxide solution that mass concentration is 5% to soak leaf powder, and at 60 ℃, keep warm for 1 hour;

[0020] (3) After washing the powder soaked in step (2) repeatedly with water until it is colorless, dry the powder at 80°C;

[0021] (4) After weighing 5g of leaf powder and 5g of sodium hydroxide powder and mixing, add 250mL of water to soak the solid matter, stir well and let stand for 1 hour;

[0022] (5) After repeatedly washing the solid substance in step (4) with water until it is colorless, dry it at 80° C. until the solid no longer loses weight, and then the adsorbent product can be obtained.

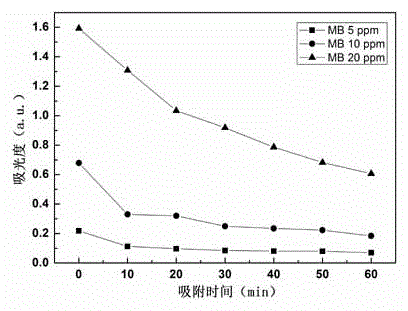

[0023] Adsorption performance evaluation was performed at room temperature: 0.05 g of adsorbent was added to 20 mL of methylene blue solutions with initial concentrations of 5 ppm, 10 ppm, and 20 ...

Embodiment 2

[0024] (1) Lechang Michelia leaves are crushed into powder, sieved, and the leaf powder with a size below 800 microns is taken for subsequent use;

[0025] (2) Soak the leaf powder in a sodium hydroxide solution with a mass concentration of 15%, and keep it warm for 1 hour at 40°C;

[0026] (3) After washing the powder soaked in step (2) repeatedly with water until it is colorless, dry the powder at 90°C;

[0027] (4) After weighing 5g of leaf powder and 10g of sodium hydroxide powder and mixing, add 350mL of water to soak the solid matter, stir well and let stand for 1.5 hours;

[0028] (5) After repeatedly washing the solid substance in step (4) with water until it is colorless, dry it at 90° C. until the solid no longer loses weight, and then the adsorbent product can be obtained.

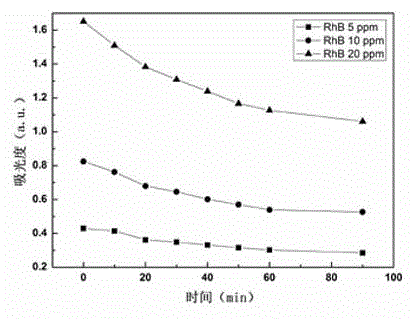

[0029] Adsorption performance evaluation was carried out at room temperature: 0.05 g of adsorbent was added to 20 mL of rhodamine B solutions with initial concentrations of 5 ppm, 10 ppm and 20...

Embodiment 3

[0030] (1) Lechang Michelia leaves are crushed into powder, sieved, and the leaf powder with a size below 50 microns is taken for subsequent use;

[0031] (2) Soak the leaf powder with a sodium carbonate solution with a mass concentration of 3%, and keep it warm for 0.5 hours at 80°C;

[0032] (3) After washing the powder soaked in step (2) repeatedly with water until it is colorless, dry the powder at 70°C;

[0033] (4) After weighing 5g of leaf powder and 15g of sodium carbonate powder and mixing, add 400mL of water to soak the solid matter, stir well and let stand for 1 hour;

[0034] (5) After repeatedly washing the solid substance in step (4) with water until it is colorless, dry it at 70° C. until the solid no longer loses weight, and then the adsorbent product can be obtained.

[0035] Adsorption performance evaluation was performed at room temperature: 0.05 g of adsorbent was added to 20 mL of methylene blue solutions with initial concentrations of 5 ppm, 10 ppm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com