Injectable mineralized collagen bone repair material and preparing method

A technology for mineralized collagen and bone repair, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problems of reduced strength, poor anti-collapse ability, collapse and other problems, achieve good biocompatibility, good bonding performance, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1, preparation of injectable / anti-collapse / mineralized collagen bone repair material

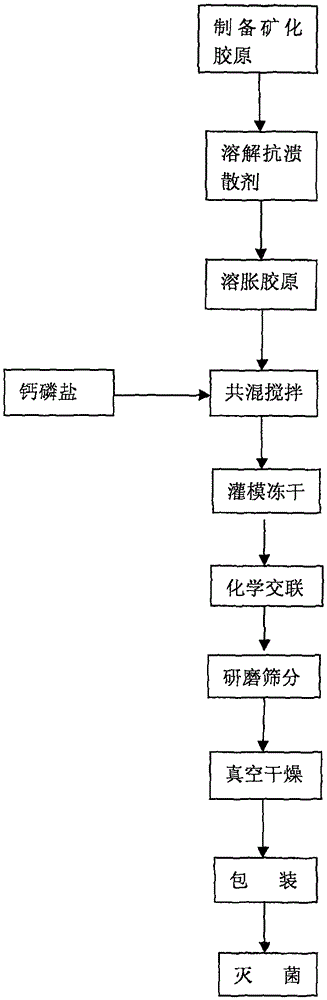

[0058] figure 1 Shown is the process flow chart of the preparation method of the injectable mineralized collagen bone repair material of the present invention. according to figure 1 In the steps shown, the preparation method of the injectable mineralized collagen bone repair material is:

[0059] Step 1.1, dissolving 1 gram of collagen in 2 L of acetic acid solution with a concentration of 0.5 mol / L to prepare an acid solution of collagen;

[0060] Step 1.2, keep stirring the solution obtained in step 1.1, and slowly add 100 mL of CaCl with a concentration of 1 mol / L dropwise 2 solution;

[0061] Step 1.3, keep stirring the solution obtained in step 1.2, and slowly add 100 mL of Na with a concentration of 0.6 mol / L dropwise 2 HPO 4 solution;

[0062] Step 1.4, continue to stir the solution obtained in step 1.3, and slowly add 1 mol / L NaOH solution dropwise until the ...

Embodiment 2

[0084] Embodiment 2, preparation of sheet-like injectable mineralized collagen bone repair material

[0085] First, prepare mineralized collagen powder, the specific steps are as follows:

[0086] Step 1.1, dissolving 1 gram of collagen in 4 L of acetic acid solution with a concentration of 0.25 mol / L to prepare an acid solution of collagen;

[0087] Step 1.2, keep stirring the solution obtained in step 1.1, and slowly add 60 mL of CaCl with a concentration of 0.1 mol / L dropwise 2 solution;

[0088] Step 1.3, continue to stir the solution obtained in step 1.2, and slowly add 30 mL of Na with a concentration of 0.12 mol / L dropwise 2 HPO 4 solution;

[0089] Step 1.4, continue to stir the solution obtained in step 1.3, and slowly add 0.5 mol / L NaOH solution dropwise until the pH of the mixed system = 7;

[0090] Step 1.5. The mixed system obtained in step 1.4 was left to stand for 72 hours, the precipitate was separated and impurity ions were washed away, followed by freeze...

Embodiment 3

[0110] Example 3, Preparation of Injectable Mineralized Collagen Bone Repair Material and Its Drug-loading Application

[0111] First, mineralized collagen powder was prepared according to steps 1-1 to 1-5 in Example 1.

[0112] Then, a sheet-like injectable mineralized collagen bone repair material was prepared. Specific steps are as follows:

[0113] Step 2.1, dry the sodium carboxymethyl cellulose in a vacuum drying oven at 50°C to constant weight, and put it in a drying vessel for use;

[0114] Step 2.2, weigh 1.2 grams of sodium carboxymethylcellulose in step 2.1, put it into a glass container with 100ml of purified water, stir and dissolve for 18 hours;

[0115] Step 3, adding 4.5 grams of collagen to the glass container in which sodium carboxymethyl cellulose has been dissolved in step 2.2, stirring and swelling for 72 hours;

[0116] Step 4.1, add 3.8 grams of mineralized collagen powder in step 1-5 to the glass container in step 3;

[0117] Step 4.2, adding 0.5 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com